We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

A well fitted drawer on traditional wooden runners is a pleasure to use.

1. Wooden slides

Traditionally, drawers have slid on wooden runners: strips of wood tenoned into horizontal rails at the face of a cabinet. In casework where a drawer will not be guided by the cabinet’s sides — for example, when the cabinet has a face frame that protrudes into the drawer opening — the runners are fitted with guides to keep the drawers from sliding left or right and binding as they’re closed.

Wooden runners have several qualities to recommend them:

- They work wonderfully when drawers are well fitted. When it comes to fine furniture, they’re the gold standard, not least because it takes finesse to make a drawer fit snugly while not so tightly that it’s a challenge to open and close.

- They require no additional financial investment beyond your labor, whereas mechanical slides cost money.

- They allow your drawer front to function as a finished face; no other face (“dummy” or “false”) need be applied.

- They let your drawer sides and joinery shine without intrusion by metal hardware.

At the same time, wooden drawer slides are less than ideal in some respects.

- They don’t allow for full extension: Once you pull the drawer out to a certain point, it will sag and can even fall out of its opening. (The well fitted example shown above is still stable at more than 3/4 of the way out.)

- A well fitted drawer can stick in humid weather in locales where humidity fluctuates significantly from season to season.

The drawer shown at the top of this post fits into this opening. The guides are precisely in line with the left and right sides of the opening and run perfectly perpendicular to the table’s face. The runner itself is just wide enough to accommodate the thickness of the drawer side. The table is fitted with traditional wooden drawer stops that go immediately behind the face. The runners and side guides have been waxed to promote smooth movement.

View into the drawer opening of a 1903 English factory made sideboard. The drawer runner is visible on the left side of the cabinet, where you can see that it’s tenoned albeit with a bit of a gap) into the front rail. To the left of the runner is a low-profile guide to keep the drawer from moving laterally as it’s opened and closed. The pyramidal object on the front rail is a traditional drawer stop. Also visible is the dust board, a thin piece of wood that resembles a cabinet bottom. Dust boards are a feature of traditional furniture fitted with drawers.

For decades now, cabinetmakers (traditionally a term that applies to makers of furniture as well as built-ins) have had access to mechanical slide hardware, the features of which have improved steadily since I was introduced to such hardware at my first woodworking job in 1981. Today there’s a dizzying variety of options offered by manufacturers such as Blum, Accuride, Salice, Knape & Vogt, and more. I’ll cover just a couple here.

Mechanical slides have a few advantages over traditional wooden runners, even if they lack the cachet that comes with a piston-fit drawer. They’re quiet, smooth-running, and allow you to pull a drawer out fully without danger of it tipping its contents all over the floor, or worse, falling out and being damaged.

2. Side-mounted ball bearing slides

Side-mount ball bearing slides such as those made by Accuride are affordable, dependable, and hard wearing. They come with a huge variety of optional features, among them a detent (helpful in cases where you want to use whatever is on the pull-out surface, such as a keyboard, without the drawer or tray closing when you touch it); extra-heavy load capacity; specialty slides for file drawers, lateral files, and so forth. Other advantages:

- They’re fantastically easy to install in casework — you can put them almost anywhere you want, mounting the support to the cabinet side or using mounting plates to attach the hardware to the cabinet’s front and back — and only impose one constraint on the dimensions of your drawer: The width of the drawer must be at or just a hair under the precise width between the slides once they’ve been installed. Beyond this, you can use these slides on drawers that are deeper (from front to back) or shallower than the slides, depending on your application. It doesn’t matter how your drawer bottom fits into the drawer — whether it’s flush at the bottom surface, fitted in slips, or slid into grooves in the drawer front and sides. While this flexibility may not sound so impressive in principle, it can be a life saver in rare circumstances where you need the combination of affordable price, full extension, and flexibility in drawer construction that such hardware allows.

- These slides allow the drawer to be removed simply by disengaging a lever. To replace the drawer, slide it carefully into position — if you don’t align the parts perfectly, you can damage the slides – -then push until you hear a “click.” Now pull the drawer out and close it fully to check the fit.

- Adjustability: Before you install set screws, the slides are adjustable up and down in addition to forward and backward thanks to slots on both parts: the part that goes on the drawer and the part that goes in the cabinet. Some models also have screwdriver-adjustable cams.

A drawer in a simple set of kitchen cabinets fitted with Accuride side-mounted ball bearing slides. This kitchen uses Accuride model 3832. One part of the slide is screwed to the interior of the cabinet; the other, visible here, to the drawer. The slides telescope to allow for full extension, which makes a drawer’s contents completely accessible.

Drawbacks? I’m not sure it’s fair to call these drawbacks, except in comparison to the Rolls Royce of the mechanical drawer slide world, which we’ll come to shortly.

- Side-mounted ball bearing slides are not completely silent; there’s a metal-on-metal sound when the arms of the slides are closing or opening, but it’s minor.

- Side-mounted slides take up space in the cabinet’s width. This space varies somewhat, depending on the model; most require 1/2″ on each side. As a result, in most applications, you need to cover the front of the drawer with an applied face. This face can be inset, as shown here, half overlay, or full overlay. When choosing these or other mechanical slides, be sure to read the specs and installation instructions to make sure the slides are compatible with your design.

- My least favorite feature of these slides is their visibility. Although they come in different finishes (many lines are available in white, black, and stainless, in addition to zinc), they do detract from the pristine beauty of a nicely finished drawer side — at least, when the drawer is open. When the drawer is closed, the slides are invisible.

The drawer closed. Full disclosure: This is my kitchen, hastily constructed in spare time many years ago. The doors at the end of this cabinet run don’t even have stops.

3. Self-closing undermount slides

Since about the turn of the millennium, cabinetmakers have had access to a type of slide that combines full extension and smooth, silent operation with almost complete invisibility. The Blum Tandem is the most widely known version, but as soon as other manufacturers (including, but not limited to, those mentioned above) saw how popular the new design was with manufacturers and their customers, they began devising their own variations on the theme.

The drawers in this bar are fitted on soft-close undermount slides.

Incongruous as it may seem, this 1915-style kitchen has drawers that run on Blum Tandem self-closing undermount slides.

Not only are these slides silent, smooth-running, full extension, and invisible; when fitted with the right locking devices (available from the same suppliers as the slides themselves), they offer a new dimension in adjustability over previous kinds of drawer slide hardware. You can move the drawer face up or down, forward or backward, tilt it (at an angle) up or down, and move it from side to side–a boon when you’re dealing with inset drawers faces in particular. But these features come with some strict requirements:

- There are precise dimensional requirements: Drawers must be just the right width and depth (front to back) to fit specific slides. These and other specifications are laid out in a handy instruction guide published by hardware manufacturers.

- You can’t just put the drawer bottom wherever you want. There needs to be a 1/2″ recess so that the door sides and front will sit over the runners. Along with this requirement, you need to drill a couple of holes at the back of the drawer for the tilt mechanism.

- Because the position of the slide hardware is fixed in relation to the drawer sides (it has to go below the drawer bottom), you need to be more precise in positioning the hardware inside the cabinet than you do with side-mounted ball bearing hardware. You must also leave more clearance in height than with side-mounted hardware, which can eat up space, depending on other elements of a cabinet’s design.

- As with the side-mounted slides, there will be a bit of space on either side of the drawer with undermount hardware. This space works out to about 5/16″ on each side. So in most cases you will want to apply a face.

A drawer on Blum Tandem undermount slides, which are invisible other than a little lever just behind the drawer face (in effect not visible in this photo).

View of the underside with the drawer pulled part-way out.

Here’s a 12″ Blum Tandem undermount slide in the closed position. The slide incorporates a frame for attachment to your cabinet; built into this frame is a full-extension runner with parts that allow for tilting the drawer to finesse the fit. The smaller piece is a locking device. (This is an older model example.) The locking device is screwed to the underside of the drawer, then clicks into place on the slide when the drawer is inserted.

Here’s the slide partially extended to show some of the mechanical parts. These slides incorporate a “soft close” feature; when you give the opened drawer a push, it closes most of the way, then at about 1-1/2″ from full closure, this mechanism comes into play, pulling the drawer home. The soft close feature has two advantages: first, it closes the drawer for you. (I’ve always imagined a little man inside the cabinet who pulls the drawer closed.) Second, and more important, it prevents the spring mechanism from snapping the drawer back forcefully, which would pose a risk to children’s fingers.

The curved-front drawers in this double vanity are fitted on self-closing undermount runners.

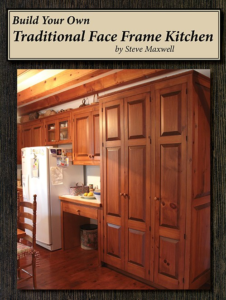

Build Your Own Traditional Face Frame Kitchen

A hands-on approach for honest, beautiful, solid-wood cabinets.

-

This interactive PDF will teach you all the steps necessary to build your own face frame kitchen cabinets. Learn about design, building the cabinet boxes, doors, drawers and how to install. With over 40 built-in videos and eleven full-size diagrams, you will learn the necessary steps to build your own kitchen.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.