We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

If you’re new to the craft of woodworking, this post is for you, and it’s to help spread the word on the brainchild of Tom Iovino (Tom’s Workbench), “Get Woodworking Week,” Feb. 3-9. Below, I’ve addressed a handful of the most common questions I get from beginning woodworkers.

Q: What’s the deal with the “I Can Do That” cutlists vs. the lumber you call out in the text? In other words, why does the text tell me to buy a 1×4 at the big box store, but the cutlist says the workpiece is 3/4″ thick 3-1/2″ wide?

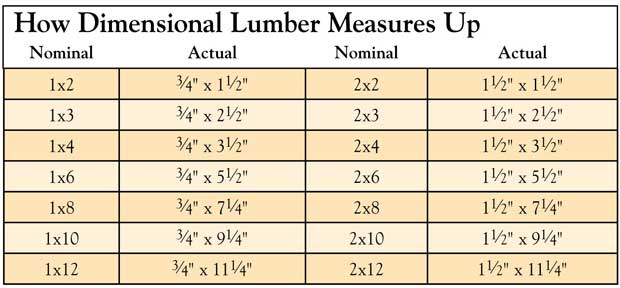

A: It’s related to the way S4S (surfaced on four sides) lumber is sold. If you go to a Home Depot or Lowe’s or Menard’s or wherever and measure what they sell as 1″ dimensional lumber, you’ll find that in reality it’s 3/4″ thick. So the text is telling you what to ask for at the store, while the cutlist gives you the actual size of the pieces.

While it’s perhaps a bit confusing, there are standards within the dimensional lumber industry. All 1x is 3/4″; all 2x is 1-1/2″ thick. As far as widths, anything marked at 6″ or less is actually 1/2″ narrower; above 6″ in width, it’s actually 3/4″ narrower. See the chart below. (Also, all of our simple “I Can Do That” articles are free online.)

Q: I want to build a workbench. What style should I build, what wood should I use and how tall should it be?

A: Not answerable in an email or blog post…get “The Workbench Design Book: The Art & Philosophy of Building Better Benches” – that will tell you everything you ever wanted to know about workbenches, whether or not you were afraid to ask.

But in brief, you should build the style that most suits your work – but perhaps the most important thing to remember is that a good bench is basically a big, heavy 3D-clamping surface – and nothing should get in the way of that purpose.

My Roubo-style bench at home, with a Benchcrafted Glide vise (and a Benchcrafted twin-screw vise stored underneath). It is 28-1/2″ tall (I am 65-1/2″ tall).

And almost any (untreated) wood will do. If it’s clear, dry and cheap, buy it (especially if it’s 3″ or thicker). And yes, you can mix species (e.g. pine for the base, maple for the top). My bench at home is white pine. Yes, it gets easily dinged (but I’d rather have my bench dinged than ding my work if I drop it on a hard bench), but it is easy to flatten.

The height of your bench will vary based on your height and the kind of work you do (and possibly on how many benches you have room for in your shop). If you have only one bench and are doing hand-tool work, it’s a compromise. You want to be able to get over your work as you plane, but not have to bend really far over as your saw (unless you have a strong back). For me, that compromise feels about right with the top of my bench level with the knuckle joint of my pinky finger when I stand alongside it. (Of course, I also have a Moxon twin-screw vise that I use for most of my sawing, and that raises the work to a more comfortable working height…because I do not have a strong back.)

Q: What tools should I buy to get started?

A: I can only assume you’re asking about hand tools…because no one ever asks me what router or table saw to buy (those are valid questions, too, but better asked of Bob Lang or Steve Shanesy). I think the best plan of attack for stocking your shop is to buy only the tools you need, and buy the best ones you can. But I don’t know what tools you need, because it varies from project to project – so decide on something you want to build, then ask me. But if you want a full list with a great explanation of each (not to mention instructions on building a place to put them, check out the explanation of the 50 or so tools (types, not brands) Christopher Schwarz recommends buying in his book “The Anarchist’s Tool Chest.” Also, download this free PDF: ToolsforWoodwork (from the Autumn 2008 issue of Woodworking Magazine).

More to come – and Get Woodworking!

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I’m building a tri fold poster display board. I want to fold the left side in, then the right side in to protect the posters during transport. I’m visualizing a u shaped hinge mounted at top and bottom but I can’t seem to find anything like that in all the hardware sites I have looked at. Does anyone have a suggestion? Thanks, jimsworkbench@hotmail.com

As to the tool bench google Bob Rozaieski or check out episodes 20, 21 and 22 at https://itunes.apple.com/us/podcast/hand-tools-techniques/id325342687 (cut and Paste) or go to logancabinetshoppe.com. Bob Rozaieski’s blogs are incredible for twice the price. They’re free, BTW. In spite the low cost of the bench in Bob’s bench it is one of the best I’ve seen.

Jb