We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I recently posted a video to our YouTube channel that discussed proper tightening of a saw blade nut (hand tightened is usually enough) and was surprised by the number of comments not on the focus of the video, but on the splitter shown on our Powermatic 66. I apologize for getting a bit technical (tool nerd!), but this is worth a bit of discussion.

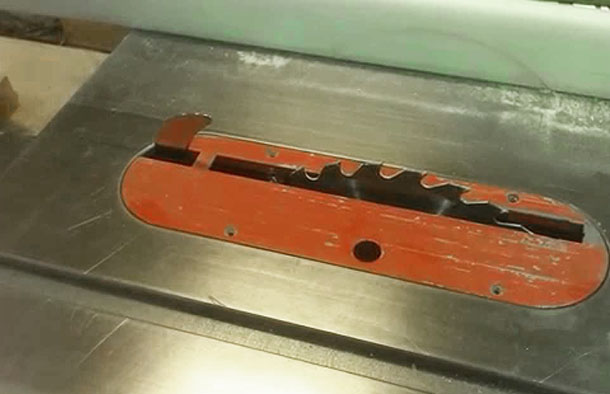

First, our Powermatic 66 table saw has been replaced with a newer model by the manufacturer, so we have used some aftermarket items to keep it safe and up to speed. One of these is the splitter shown above (made by Biesemeyer a number of years ago). But before I get too far I want to point out that this is a splitter, not a riving knife. A splitter mounts behind the saw blade and essentially stay right there. While the blade moves up and down, the splitter remains in a constant location and the distance between the teeth of the blade band the splitter changes (below), widening when the blade is lower, and reducing the effectiveness of the splitter.

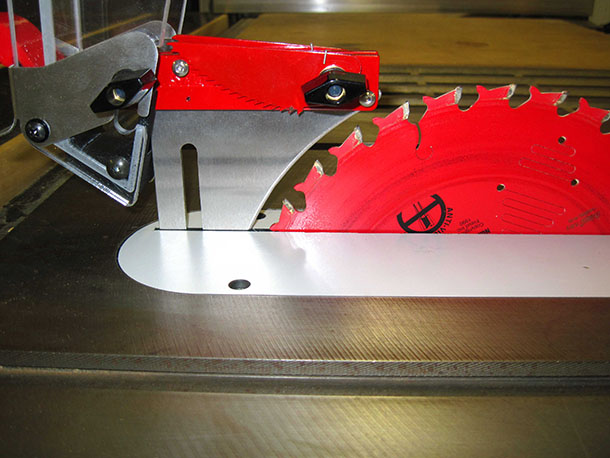

A riving knife is designed to move with the height of the blade and maintain a close clearance distance between the knife and the blade — a safer option.

The Shark Guard Ark Shown in place.

As you might imagine, to keep the distance equal with the blade requires some extra parts under the top. So, if you have an older table saw like ours, you’ll be looking for an aftermarket part for the conversation.

A number of years ago (I apologize for not quoting the date) saw manufacturers answered the call for improved safety on their machines and started to include true riving knives in the mechanics of the saws. Hooray for them and for us! But that left those of us with very decent machines wanting, and the aftermarket for splitters was created. I say splitters because that’s really what’s available as adding a riving knife is taking aftermarket additions to a complicated (or impossible) level.

There were and are a number of splitter designs available, and a fair number of videos and articles on making your own (not my first choice.) I am very happy with our Biesemeyer splitter, but unfortunately, it’s no longer available for Powermatic saws. Though I haven’t had the opportunity to try it, I have found a similar product from a company called Shark Guard. Interestingly enough, they also offer an adjustable riving knife design! They’ve added the option to adjust the height of the knife to mimic a riving knife. Neat.

So, bottom line, if you’ve got a newer machine with a riving knife, use it! If you’ve got an older machine that can be upgraded with aftermarket items to keep it safer, do it! Oh, and don’t get me started on anti-kickback pawls…that’s another post!

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.