We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

The first time I ever tried steam bending wood, it took two of us to pull the scalding hot ash against the bending form and then clamp it down before it cooled.

While it was an amazing experience, it was something I had difficulty doing on my own with just pure muscle (you will never see me shirtless in a beefcake calendar. Perhaps in a stringbean calendar…).

Years later, bodger Don Weber showed me his windlass device for bending arm bows for Welsh stick chairs. We used it to bend seven arm bows one day, and (to my surprise) no one was killed. I exaggerate. I’m almost certain the device is safe.

I work alone. I am not a beefy dude. I don’t like to build contraptions. So I use a tail vise to bend my crest rails and arm bows. The screw feed on my tail vise, which is actually a quick-release vise, makes it so easy that a child could do it. Here is a photo essay:

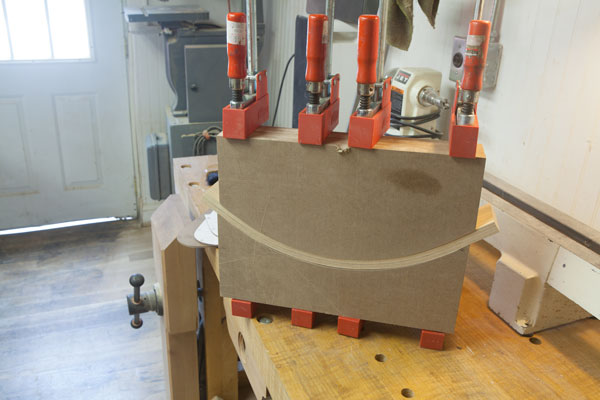

The form is made from pieces of MDF that are stacked together. No, the MDF doesn’t fall apart when you put steamed wood in it. At least, it hasn’t for the first 20 bends I’ve made with this form. The concave section of the form is placed against a dog in my benchtop. The convex section of the form is clamped to the movable jaw of my quick-release vise. The form also is butted against the metal dog in the vise.

Both halves of the form sit on thin pieces of Masonite. The Masonite acts as a flat floor for the steamed workpiece I put in the form and prevents it from falling to the floor.

After I steam or boil the wood for an hour, I put it between the two sections of the form.

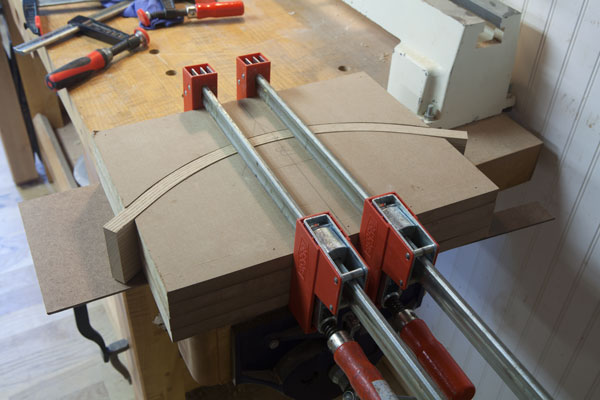

Then I crank the jaws closed. The effort is minimal.

When the bend is complete, I then use bar clamps to press the forms together. Then I release the vise and can put the whole thing aside for a few days so the crest rail will set and hold its shape.

The setup for arm bows is very similar, but it involves a few more clamps. Next time I need an arm bow I’ll document that process here as well.

— Christopher Schwarz

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Hi,

I’m planning to build a pergola for my patio. The patio came with the house and the edge facing the backyard is curved. Your article on steam bending gave me an idea…why not steam bend, laminate and glue 3/8 inch x 10 inch lengths of Doug Fir? I’ve got a 14 inch band saw with a 14 inch throat as well as a re-saw blade. also a 14 inch planer. I can drive stakes at the patio’s edge to form the lengths of Fir against. (I’ve got a lot of clamps.) I thought I could reduce the weight by using spacer blocks, thereby making it hollow. This would, in turn make it possible to run wiring in conduit through the beam to the support columns (I’d like to install an outdoor fan with light). I have only one question: Is Do0uglas Fir amenable to steam bending. Any advice would be welcome.

Thanks,

Nick

How thick would you go with this technique Chris? I have to make a boat tiller