We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Acombination belt-disc sander is similar to a mid-round draft choice on an athletic team. It’s not a priority purchase, like a tablesaw or planer, but it’s valuable in a woodworking shop as a role player. It’s two tools in one. The disc is great for precise edge work, like fitting miter joints and trueing outside curves. The belt allows you to flatten faces and edges, shape contours and smooth inside curves. We tested 18 combination sanders that cost $500 or less. Some are benchtop models; others come with stands. All these sanders are equipped with 6-in. x 48-in. belts and 9- to 12-in.-dia. discs. These are not industrial-quality machines (see “Consider These Alternatives,” ), but they’re a good fit in small pro or home shops where they won’t be used constantly. The sanders in our test fall into two categories (Figs. A and B). Machines priced under $300 have limitations in capacity, power and ease of operation compared with those that cost more. Still, the fact is some of these lightweights deliver good value. We found several likeable sanders in the $300 to $500 category, including some real workhorses.

|

|

|

|

Effective Dust Collection

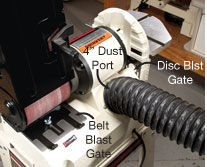

Don’t buy a sander that doesn’t provide ports for dust collection. Look for large-diameter ports, which restrict airflow the least. Most sanders we tested have separate ports for the belt and disc. These machines require two separate hoses (and blast gates) or moving a single hose to the disc or belt, depending on the job. Many machines make moving the hose inconvenient, because the two ports are different sizes or awkwardly located. Sanders with a single dust port for both disc and belt are most convenient to hook up (see photo, left), but unless they have separate blast gates for the disc and belt, they aren’t as effective as separate ports. Sanders with onboard dust collection are only worth considering if you don’t have a dust collector or shop vacuum. Onboard collection is definitely better than nothing, but it’s not as effective as collection with a separate machine. A dedicated dust collector equipped with a filter bag capable of removing the tiniest dust particles is your best choice. A shop vac with good filtration is an adequate substitute.

Effective dust collection is a top priority, because combination sanders spew clouds of fine dust. Blast gates concentrate the suction to the tool being used. |

|

Protective Shrouds

Combination sanders and your fingers don’t mix. Both disc and belt operate simultaneously, even though you only work on one of them at a time. Unintentional contact with the abrasive can be painful. Belt and disc shrouds minimize your exposure. The best belt shrouds cover the bottom, back and top of the belt. Many machines leave the top and back uncovered, which is especially dangerous if the belt is positioned vertically. For durability, we prefer metal shrouds. Sanders from Bridgewood and Lobo come with covers that shield the front of the disc when you’re working on the belt. Every machine should have them—and similar covers for the belt.

Full shrouds protect against accidental contact with the abrasive—and instant regret. A removable top allows you to sand inside curves on the roller. |

Direct-drive systems transmit power efficiently and reduce vibration by eliminating pulleys and belts. Instead, the belt and disc mount directly to the motor’s driveshaft. |

Plenty of Power

The disc or belt shouldn’t slow significantly during use. Horsepower and amperage ratings don’t tell the whole story, because they don’t indicate how effectively the power is transferred. Belts can slip and pulleys can be out of alignment. Both conditions eat power. In our tests, sanders with direct drive were less likely to slow down than belt-driven models with motors of similar size (see photo, above right). The downside of direct-drive sanders is that the dedicated motor may be both expensive and difficult to replace. We were able to find “sweet-spot” speeds for both belt and disc sanding on the variable speed sanders, which are belt driven.

User-Friendly Speed

Speed, abrasive choice and feed rate are all related. For safety, and for fast results without clogging the abrasive or burning the wood, we prefer the combination of coarse abrasive (60 grit), slow speed and a light touch. Sanders with variable speed control allow you to dial in exactly the speed you want. Sanders with 9-in. discs rotating above 3,000 rpm (the case with several light-duty sanders) are scary-fast. Sanding with one of these speed demons requires an experienced operator. All the 12-in. discs rotate at about 1,720 rpm, which we found to be effective and user-friendly. Belt speeds under 1,500 feet-per-minute (fpm) are too darn slow.

Securely locking tables are a must

|

|

|

|

We prefer tables mounted on trunnions (left) or pivot arms (center) because they lock securely. Cast trunnions (typically found on industrial sanders) are the traditional choice, but stamped steel pivot arms are just as effective. Long levers are best for locking the table securely. Tables mounted on a single post (left) are much less effective. They can work loose and allow the table to rotate.

Dedicated Table that Lock Securely

We recommend sanders with separate tables for the disc and belt. Light-duty sanders often have only one table that serves both. These dual-service tables mount on a post, which is only held in place by setscrews. No matter how tightly you reef on the setscrews, typical back-and-forth sanding action can cause the table to work loose.

Most medium-duty sanders have dedicated tables mounted on trunnions or pivot arms (see photos, above). Trunnions are cast iron or aluminum alloy. Stamped steel pivot arms depend on a perfect fit at the pivot pin. Usually the pin is threaded, so you can tighten it.

Cast Iron Where It Counts

Cast-iron tables are best because they dampen vibration. Large tables provide better support. Most of the sanders we tested come with miter gauges that are merely adequate. Tables with standard-size miter slots make it easy to upgrade to a better-quality miter gauge.

A 12-in.-dia. disc has 6 in. of usable width, because only the portion that rotates toward the table can be used safely. You lose 1-1/2 in. of usable width with a 9-in. disc. |

|

A 12-in. Disc and a Large Drive Shaft

Because of its rotation, you can only use half of the disc safely. Sanding on the half that rotates away from the table is dangerous—be sure to use only the half that rotates down toward the table. Opting for a bigger disc seems like a no-brainer. A 12-in. disc allows sanding widths up to 6 in., so you can true up miters on pieces as wide as 4 in. A 9-in. disc maxes out at 4-1/2-in. widths and can only handle miters on 3-in.-wide stock. Almost all of the discs in this test are made of aluminum (industrial sanders have discs made of machined steel or cast iron). While the 9-in. aluminum discs were similar from sander to sander, we found significant variations in the 12-in. discs. The heaviest 12-in. discs weighed 25 percent more than the lightest and had almost twice the wall thickness. For precision work like truing up miters, the disc must be rigid. Deflection wasn’t an issue on the sanders we tested with 9-in. discs, but it was on some sanders with 12-in. discs. We found that the most rigid 12-in. discs were mounted on sanders that had large-diameter drive shafts—at least 3/4 in. (19mm).

Disc abrasive changes are easiest if the lower shroud gives you room. On many sanders, you have to remove a cover that’s screwed to the shroud. |

|

Easy Access for Disc Changes

You probably won’t change the disc abrasive as often as you should if you can’t get to it. This task always requires removing the disc table, but on the best sanders, that’s all you have to do (see photo, above). Here’s a tip: Put away the lacquer thinner. Use a citrus-based adhesive remover to clean the disc before installing the new abrasive (3M’s citrus-base adhesive remover is available at www.OfficeMart.com, MMM6040, 5-oz. aerosol, $5).

All 12-in. discs aren’t created equal. Better ones are thicker, reinforced and balanced, and they have a larger bore. All 12-in. discs aren’t created equal. Better ones are thicker, reinforced and balanced, and they have a larger bore. |

|

Choosing Abrasive Belts and Discs

Choosing the “right” belts and discs isn’t a life or death decision, because they aren’t very expensive. Top-quality belts cost less than $10 and discs less than $5. Economy abrasives cost about half as much. Here are some guidelines for good sanding service.

1. A coarse, “open-coat” abrasive (60 to 80 grit) is the best choice for most general-purpose sanding. It cuts aggressively, so you can sand with a light touch, which is easier on the sander and safer for you.

2. Sanding belts with a heavy backing material (X- or Y-weight fabric) stay cooler and hold their shape better during use. Unlike belts, sanding discs are firmly attached to a solid surface, so lighter-weight backings are fine for them.

3. Aluminum oxide or zirconium oxide abrasives are the best choices for sanding wood. Silicon carbide is best for sanding metal.

4. An antistatic coating on the belt or disc removes static charges created by sanding. Did you ever notice how sanding dust sticks to everything? That’s because sanded particles are statically charged. Using belts and discs with an antistatic coating can leave you with a cleaner shop: Noncharged sanded particles remain suspended, so they’re more easily captured by your dust collector. Don’t use antistatic belts or discs without dust collection—the particles will just hang in the air.

5. Keep a belt-cleaning stick at hand and use it often (8-in.-long stick, BS99801, $8, Klingspor’s Woodworking Shop, (800) 228-0000, www.woodworkingshop.com).

|

A cleaning stick extends the life of any belt or disc. Used frequently, it’s the best abrasive-related investment you can make. |

Easy Belt Arm Positioning

The belt arm pivots to allow sanding at any angle. A split collar makes position changes easy because it locks at a single point (see photo, top left).Your other choice is a slotted dual-ring mechanism that locks with two or three bolts, which are often hard to reach.

Adjusting the belt arm should be simple. A split collar lock mechanism is best. |

Gaining access for belt changes shouldn’t be too complex. Some sanders require more than one tool and leave you with numerous loose parts. |

Easy Belt Change and Adjustment

Changing abrasive belts takes multiple steps, and getting hung up on any one of them makes the job a chore, especially if you change belts often. First you have to get to the belt, which requires removing the dust collection and belt shrouds. On many sanders, this is a tedious operation, but it should be simple, tool-free and fast To change belts, you have to release the belt tension. It’s easy if the sander is equipped with automatic belt tensioning and a pain if it isn’t. After the new belt is installed, you have to adjust the tracking to make sure it stays centered on the platen during operation. Automatic tensioning mechanisms use spring pressure to compensate for minute differences in length between belts. They also keep belts properly tensioned as they stretch during use. Most of the sanders we tested use one of two types. Mechanisms designed around a post-mounted yoke are most user-friendly. Contour sanding using the top roller isn’t possible with side-mounted mechanisms, because only one end of the roller is supported.

|

|

Automatic tensioning makes belt changes easy. We prefer mechanisms with a yoke that supports both ends of the roller and an on-off lever to set and remove the tension (see photo, far left above). Belt tracking adjustments are simple because they’re made with a single knob. Side-mounted mechanisms are harder to use, because they’re spring-loaded (see photo, left). You have to hold the lever down with one hand while removing or installing the belt with the other. Belt tracking adjustments require two knobs.

A Graphite Platen Pad

Many sanders have a graphite-covered pad affixed to the platen to reduce friction between the platen and belt (see photo, below). With a pad, the belt slides more easily and requires less power, so it’s less likely to slow significantly during use. The belt also stays cooler, so it’ll last longer. In addition, the pad dampens vibration and compensates for a platen that isn’t flat—because the pad is a wear surface, high spots will simply be worn down. The only downsides: New pads slough bits of graphite and handling the pads leaves your hands dirty.

A 6-in. x 36-in. graphite roll is available from Klingspor’s Woodworking Shop, www.woodworkingshop.com, (800) 228-0000, GR03062, $7. A Paddle-Style Off Switch A paddle-style switch makes it easy to shut down the sander in an emergency. If your hands are busy, you can operate a paddle switch with your knee.

A graphite pad improves sanding by reducing friction. Concentrated sanding can create a low spot (inset photo), but the pad is easy to reposition and inexpensive to replace. |

A stop arm makes sanding easier and safer, because it keeps the belt from ripping the workpiece out of your hands. Its location should allow full-length use of the belt platen. |

Flatten the Platen

A cast-iron belt platen isn’t necessarily better or flatter than one made of stamped steel. The least-expensive machines we tested have cast-iron platens; some of the more expensive machines employ stamped steel. We didn’t notice significant differences between them during our test, but we did find an easy way to flatten platens made of both materials. A perfectly flat platen isn’t absolutely necessary, because the belt isn’t intended for precision work. However, sanders ran more smoothly and quietly after their platens were flattened, reward enough for the 10 minutes we spent doing the job and the belt that we sacrificed.

First, joint the face of a 3- to 4-in.-wide board that’s long enough to bridge the platen’s entire length. Disconnect the dust collection hose. Turn a clean used belt inside out and install it abrasive-side down. Start the sander, position the flattening board on the platen and bear down lightly as you move it back and forth. Don’t bear down hard enough to stop the belt, or you’ll score the rollers. Stop and check the results frequently.

Flatten the platen with an inside-out belt and a flat-bottomed board. |

|

Recommendations

We found several combination sanders priced between $400 and $500 that are worthy of your hard-earned cash. These machines feature sanding performance similar to that of more expensive industrial sanders, but they’re not as heavily built. Our Best Buy award winners provide good value. Combination sanders that cost less than $300 are small, light-duty machines. These sanders usually include compromises that affect user-friendliness and performance. Some models are worth a look, if you’re willing to compromise.

Bridgewood

BW648BD, $430

In addition to being a top performer, this sander is a great value.

Pros

• The platen is heavy gauge steel (twice as thick as other stamped steel platens).

• The cast-iron belt tensioning mechanism is one of the best.

• The well-made disc threads onto the 1-in. drive shaft and doesn’t visibly deflect.

• Both tables lock solidly.

• Dust collection is excellent.

• Belt and disc are both fully shrouded, including front covers for the disc.

Cons

• Access to the disc for abrasive changes is sub-par.

• Adjusting both the belt table and the belt arm requires a wrench.

• The miter gauge is only average.

• Heavy sanding pressure slows the belt slightly.

Woodtek

Woodtek, 923-810, $500

Aluminum-alloy body castings lend an industrial-quality appearance.

Pros

• Its 2-hp motor is powerful.

• Cast-iron tables and belt platen are rock-solid.

• The disc shows no visible deflection during use.

• Access to both belt and disc is easy.

• Adjusting the belt arm is easy.

• The backs of both belt and disc are fully shrouded.

• The miter gauge is above average.

• Dust collection is good. We made it better by replacing the small disc port with a larger shop-made one.

Cons

•The operating mechanics of the belt-tensioning arm and belt-tracking knobs are hard to figure out, and the operator’s manual is of little help. Once you understand the system, though, it works well.

• Sanding on the top roller isn’t recommended, because the roller is not supported on both ends.

• The disc table is hard to lock, because the adjustment wheels are small and located too close to the trunnions.

• The belt table is easy to adjust, but it’s a pain to remove.

Woodtek

81091, $300

This benchtop model is the most compact direct-drive sander in the test.

Pros

• This model is one of only two machines under $300 with separate tables for the disc and belt.

• The tables lock solidly, but they’re relatively small.

• The 1-hp motor is gutsy.

Cons

• The 9-in.-dia. disc spins too fast.

• Dust collection is good off the disc but could be better off the belt.

• The belt isn’t completely shrouded.

Craftsman Sanding Center

21516, $470

Plamgren Sanding Center

81221, $500

These unusual machines give you three sanding tools

for the price of two. Mechanically, they are identical.

Pros

• The oscillating spindle easily makes these sanders best-in-the-test for shaping concave curves.

• Variable speed control allows you to match sanding speed with the job or your comfort level.

• The dedicated trunnion-mounted cast-iron tables are equipped with long lock levers.

• The 1-1/2-hp motor has good power through normal speed range (though it loses torque above 2,400 rpm/ 1,900 fpm).

Cons

• These are big, heavy machines; moving one is a two-person job.

• The onboard dust collection doesn’t work well enough on the belt.

• The disc deflects slightly.

• The belt wanders a bit.

• The belt isn’t completely shrouded.

Consider These Alternatives

Industrial Belt-DIsc Sanders

A $200 price jump from the most expensive sanders in our test gets you an entry-level industrial sander. The Delta 31-300 ($700) features a machined steel 12-in. disc, a cast-iron belt arm-platen assembly and huge cast-iron tables mounted on machined steel trunnions. Other features include full shrouding, easy belt and disc changes and adjustments, user-friendly knobs and handles and through-the-base dust collection with a single 4-in. port.

Stand-Alone Disc Sander

Benchtop 12-in. disc sanders feature trunnion-mounted cast-iron tables and dust collection ports. Prices start well under $200.

Easy Sander

An edge sander turns the belt on its side and features a long table that adjusts vertically, so you can use the belt’s entire width. On more expensive machines, the belt oscillates. A second table around the end roller makes it easy to sand concave profiles. Prices start around $400.

Different Sander Combinations

The Grizzly G0529 ($395) features a 12-in. disc with an extra-deep cast-iron table mounted on stamped steel pivot arms. The spindle oscillates in a 1-in. vertical stroke, accommodates up to 2-in.-dia. sanding drums and is surrounded by a generous cast-iron table. Power is supplied by a 1-hp, 1,725 rpm, direct-drive motor.

Worth a Look

Central Machinery 40643, $290

The only sander priced under $300 with a 12-in. disc and two cast-iron tables

Pros

• The trunnion-mounted tables lock solidly.

• Dust collection ports are barbaric, but surprisingly effective, once you make your own hose adaptor for the disc.

• A cam-operated quick-release lever sets and releases belt tension.

Cons

• The disc deflects noticeably.

• The belt slows easily.

• Belt tensioning and tracking adjustments require an Allen wrench.

• The miter gauge is a toy.

• Table slots are milled too wide for a standard-size replacement.

• There’s no belt shroud.

Grizzly

1014Z, $220 The best of the rest.

Pros

• It has plenty of power.

• It’s equipped with a cast-iron disc.

• The platen/belt arm assembly is cast iron.

• It features adjustable belt tensioning with a quick-release lever.

• Dust collection is very good.

Cons

• The post-mounted table doesn’t lock solidly enough, especially on the belt, where the post mounts off to the side, instead of under the sanding action.

• The belt stop limits usable platen length.

• The belt isn’t completely shrouded.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.