We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Last Saturday was an interesting day. My son, Hayes, and I delivered a large, private banquet room table to a popular restaurant that’s moving to a new downtown location in a couple weeks. He landed the job as part of an order for 15 or so other various-sized dining tables in the public part of the new restaurant space. His woodworking business has been keeping him busy since the first of the year.

Last Saturday was an interesting day. My son, Hayes, and I delivered a large, private banquet room table to a popular restaurant that’s moving to a new downtown location in a couple weeks. He landed the job as part of an order for 15 or so other various-sized dining tables in the public part of the new restaurant space. His woodworking business has been keeping him busy since the first of the year.

This 14′-long table is supported by three pedestals and is made from 8/4 recycled white oak lumber. That lumber was originally used for horse stables at a nearby race track. Neither the table design or the use of the material was his idea; it just fit the interior design specs. It was awful to work with – trust me.

What made the day interesting for me was the experience of standing at the intersection of my past and my future. As you may know, I’ll be retiring soon from Popular Woodworking Magazine after a near 19-year stint. In my retirement I’ll be working somewhat regularly with Hayes in the shop, helping him when he needs it and working on my own projects when he doesn’t. We’ve shared shop space for several years now so it should be an easy transition for me and, I hope, for him. It’s great to share my experience with him. And I learn new things from him as well.

The intersection with my past was not so much my time with the magazine but my years in the custom furniture and cabinet business. In one shop I helped manage, one of our specialties was very large, very expensive boardroom conference tables. I think the longest one we ever made was just over 40′. It was so big there were built-in microphones that would rise up though the tabletop with the flip of a switch. Building these amazing monsters required more than a few engineering tricks, especially when large fields of the tabletops were inset granite or marble slabs, or fancy veneered panels. Helping Hayes figure out the logistics of his first big table allowed me the chance to dust off some of those old tricks and hand them down to the next generation. It felt good.

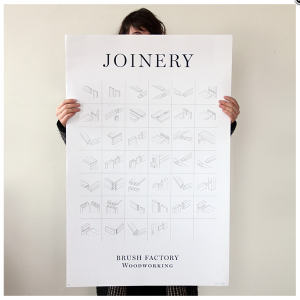

Hayes came to woodworking as an outgrowth of his industrial design degree and a desire to build some of the work he designs. I didn’t push him into woodworking but he certainly had a lot of exposure to the shop growing up. Actually, I preferred he pursue his natural ability to draw and his developed sense of scale and proportion. For a time in college, he contributed a hand-drawn illustration each issue of Popular Woodworking. He continues to use those illustration skills as you can see in his “Joinery” poster here. And allow me make a shameless commercial pitch – you can order one from his web site and have a beautiful poster on highest-quality paper. And you will lend support an up and coming, but still struggling, woodworker. Brush Factory, by the way, is the name of his business. It’s taken from the original occupant of the shop we now occupy, the “Cincinnati Brush Manufacturing Co.”

I’m grateful to be retiring in good health and have some quality years to spend in the shop doing some serious (and sometimes not-so-serious) woodworking on a relaxed schedule. That I can do this sharing shop space with Hayes will make it extra enjoyable.

– Steve Shanesy

p.s. Hayes also did many of the illustrations for Bob Flexner’s book, “Flexner on Finishing” (on sale right now for $15.59 in hardcover).

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Also we need an article on your experience with *large* tables.

August issue will do. 🙂

Wow Steve, sounds like the beginnings of an exciting chapter for you both. Best of luck!

I hope to be so fortunate that one day my sons will want me around their workplace 🙂 You done good Steve!

Great story, Steve! Sounds like you’re continuing to fight the good fight. But how about taking on an additional one? I want to know more about the Cincinnati Brush Manufacturing Company, The Columbus Washboard Company, The Columbus Whistle Corporation, and all the other little Ohio industries that have come and gone or continue as “the only one still existing in America”. I’m sure that there must have been hundreds in Cincinnati.