We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I spend hours looking at photos of furniture. If I don’t have my nose buried in books, I gaze upon photos sent to me by other woodworkers. In a flickr set sent to me by Mark Firley (thanks, Mark), I stopped on a bow-front chest photo. (I think Mark was on a dovetail expedition that day; each piece of furniture he snapped also has a close-up look at drawer dovetails.)

I spend hours looking at photos of furniture. If I don’t have my nose buried in books, I gaze upon photos sent to me by other woodworkers. In a flickr set sent to me by Mark Firley (thanks, Mark), I stopped on a bow-front chest photo. (I think Mark was on a dovetail expedition that day; each piece of furniture he snapped also has a close-up look at drawer dovetails.)  The chest, as shown in the left-hand photo, is nice, but it was the photo right after that really caught my eye.

The chest, as shown in the left-hand photo, is nice, but it was the photo right after that really caught my eye.

Take a look at the pins on the drawer pictured at the right. The pins are extremely thin. So thin, in fact, that there is only room for a saw blade to enter the pin waste area in order to make the cut. True pin dovetails. This method of work brings about discussion on the strength of these dovetails. Do you think these pins and tails have the necessary strength?

Before you respond, let me tell you that Frank Klausz swears drawers built with this dovetail layout will fail; the pins will break off. Also, take a look at the photo of the second drawer on the chest. It’s shown below.

Before you respond, let me tell you that Frank Klausz swears drawers built with this dovetail layout will fail; the pins will break off. Also, take a look at the photo of the second drawer on the chest. It’s shown below.

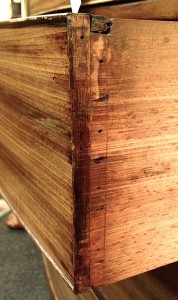

What you should see (you can enlarge the photo by clicking on it) are the obvious round holes in the center of each tail. The only rational conclusion you could make is that this joint failed and was, at one point in time, reinforced with nails, round wire-cut nails.

Before you make these ill-fated dovetails on your project, you may want more dovetail instruction. At shopwoodworking.com, we only have 100+ dovetail related DVDs, articles and downloads from which to choose. I’m not sure why, but I am extremely fond of this particular product. You may be, too.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Actually single entry pins are fairly strong, especially in hardwoods. The only load on them is created when the drawer is pulled forward out of the case. Damage occurs when the drawer gets wracked from misuse. They are much quicker to cut as there is very little material to remove from the pin hole so it just takes a quick whack on each side. This was all piecework and these guys were moving fast to get their money. Remember this wasn’t done for looks back in the day. Hard to do with a router though!

PYdesign beat me to the punch by suggesting more pins. But the other issue is glue failure. More small pins would allow for more glue and joint integrity. In the photo it’s hard to tell if the pins failed or the glue stopped doing it’s job and let loose. Nails would suggest holding the sides in place, while dowels would suggest pin failure. Of course, it all depends on the expertise of the person who did the repair. .

Boy these dovetails are nice to look at, but man what a waste of time, and a guarantee of future repair . Even John and Thomas Seymour changed their ways after needing to repair their own dovetail drawers.

I have repaired several drawers that have failed because they had been heavily loaded and the thin pins had failed. I do not like the appearance of thin pins in these applications and suspect that this is because I intuitively feel they are too weak.

Thin pins can sometimes look good on light duty boxes when they complement the wood being used. I even like cistern layouts, where the pin is the same size as the tail, when they are used in heavy duty jobs with strong woods. They were though to be unattractive though that was in the days when end grain was considered to be offensive. The lower skirt .and similar parts of anarchists chest are best made with these IMHO. I sometimes feel that thin is only a fad and I do not like over thin models and overthin pins. The pins should match the job

I think you are right Glen about these pins being too delicate for heavy drawers. Boy they look pretty on small desk drawers and boxes, though!