We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Since taking my hobby woodworking more seriously I’ve tried a few different honing mediums, but I always seem to come back to the venerable India combination stone that’s used by all the joiners in our workshop. It’s always had a dash of oil when in use and think no more about it. However, most of my hobby projects are much smaller than the general joinery products I’m involved with and I have noticed a bit of residue from the honing process where it is not welcome.

I don’t have a separate area for honing and I like to have my stone at hand on the bench when I need it. So I thought why not hone dry? We all know that whatever solvent is used during the honing process is there to float the particles away and prevent clogging. Hone dry and the stone will load and eventually stop cutting. How long my India would take to load to the point of being useless was an unknown.

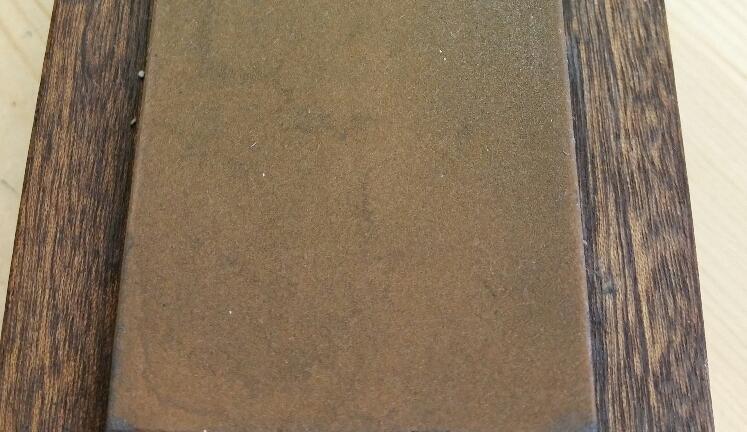

Let the experiment begin. I scrubbed the stone with abrasive soap (Swarfega) and warm water to remove any residue. By the book, this stone will not be totally dry because India stones come pre-soaked in oil – but there will be no solvent used so it’s as dry as I’m going to get it.

The shot above is as clean as I could get it without taking any further steps. So to put it to work, I honed a Stanley No. 5-1/2 Iron. With the Stanley iron being so thin I tend to hone the whole bevel; on thicker stuff I’ll remove the bulk with a grinder. Despite the dry surface honing felt fine; I think I subconsciously used a lighter touch. I observed the surface loading up but the stone still cut well enough for a finishing stone. I would also say it produced a finer edge, not that I wanted or was looking one but nice just the same. Below are the results and you can see the surface of the stone beginning to clog.

I also honed some chisels using my normal secondary bevel method and that worked really nicely. Working a smaller area meant the stone loaded much more slowly. I had a few hours of work and honing, and it worked out very well. It’s not totally clean as there is still metal swarf about, but it is significantly cleaner. At the end of the session I scrubbed it once again with warm water and abrasive soap and it removed the swarf quite nicely.

I don’t think anyone should be in a hurry to change what they do and I don’t think I’ve broken any new ground but I’m quite happy to hone dry and wash at the end of the day, especially if it keeps any unwelcome marks away from my projects! I can see me using this method when there is a day of finer work at the bench needing regular honing; when it’s normal workflow I’ll probably add a splash of oil. The most important thing was the wood didn’t care – you find it normally doesn’t as long as you’re sharp.

— Graham Haydon

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

This is the sort of thinking that most impresses me. Many many things are possible; most , however, are not. Differentiating is the mark of genius, because we don’t have time to try everything.

Now I must consider the consequences of dry diamond sharpening, heck, it can’t clog very much there’s steel under there.

There, that wasn’t very hard.

Thanks.

A trick I learned from some old tool+die makers is soak the India stone in kerosene to clean it.

Thanks, definitely going to start doing this. I work with a lot of Ash. An oily fingerprint with iron shavings in it has a pretty extreme reaction due to the high tannin content. I don’t mind cleaning up at the end of the day, but I don’t like to run in the house after touching up an edge just to scrub my hands clean.

I don’t use oil stones my self, but a very nice article, well put together.

Well done Graham