We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

The hand tool versus power tool discussion is something that comes up frequently at work (at least where I work these days). Prior to 2007, however, I didn’t even know it existed. In August of that year I decided to open a woodworking school and began writing for Popular Woodworking Magazine. Prior to that I was building furniture every day and had no idea there were wars raging in the woodworking community at large. In fact, I didn’t even realize there was a woodworking community at large.

The hand tool versus power tool discussion is something that comes up frequently at work (at least where I work these days). Prior to 2007, however, I didn’t even know it existed. In August of that year I decided to open a woodworking school and began writing for Popular Woodworking Magazine. Prior to that I was building furniture every day and had no idea there were wars raging in the woodworking community at large. In fact, I didn’t even realize there was a woodworking community at large.

As a full-time maker, there wasn’t usually time to read magazines or frequent forums. Honestly, I didn’t know there were that many of either out there. And to find out that people were trying to decide whether hand tools were better than power tools (or vice versa) was a concept that was totally foreign to me.

Having worked my entire adult life in the fine custom furniture business, the only woodworkers I knew were making furniture pretty much the same as me. Sure, there were the furniture makers who leaned heavier in one direction than another, but everyone was pretty much blended (or what the magazine often refers to as “hybrid”). Let’s face it, customers willing to pay for handmade furniture actually want some of it to be touched by the maker with hand tools.

Having worked my entire adult life in the fine custom furniture business, the only woodworkers I knew were making furniture pretty much the same as me. Sure, there were the furniture makers who leaned heavier in one direction than another, but everyone was pretty much blended (or what the magazine often refers to as “hybrid”). Let’s face it, customers willing to pay for handmade furniture actually want some of it to be touched by the maker with hand tools.

Because we were all making furniture for a living, we had to use power equipment to some degree or another. It’s not easy making a living building furniture today and it’s twice as hard if you plan to do it 100 percent by hand. For me it wasn’t a philosophical choice – it’s just what everyone did.

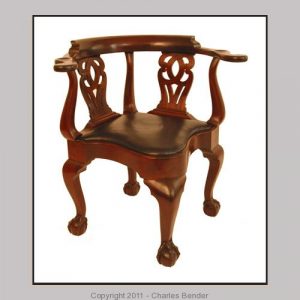

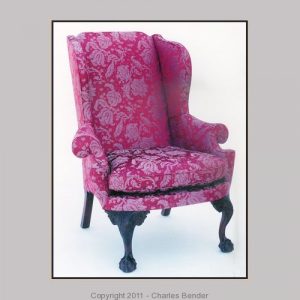

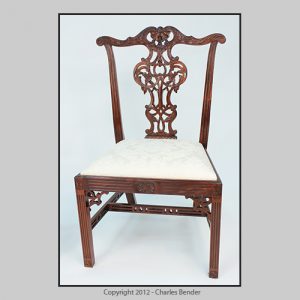

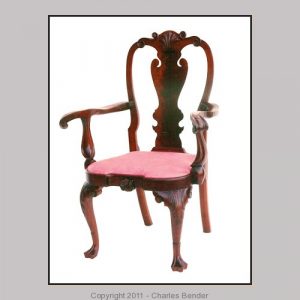

One area of woodworking where being blended helps tremendously is making chairs. Sure, 18th-century chairs were made entirely with hand tools, but we don’t live in the 18th century. Having made hundreds of chairs, I can tell you there’s no substitute for machine repeatability when it comes to joinery – but no matter how much I do with power tools, there are always joints that need to be fit precisely by hand – not to mention and all that decorative carving.

One area of woodworking where being blended helps tremendously is making chairs. Sure, 18th-century chairs were made entirely with hand tools, but we don’t live in the 18th century. Having made hundreds of chairs, I can tell you there’s no substitute for machine repeatability when it comes to joinery – but no matter how much I do with power tools, there are always joints that need to be fit precisely by hand – not to mention and all that decorative carving.

One of the greatest benefits of blended woodworking is that you can create projects of a higher skill level and quality in less time. Using the most efficient tools for the job means you can concentrate on learning and perfecting the skills that make the project different from something made in a factory. Working in this manner has allowed me to concentrate on my joinery and carving skills. To my mind, those are the things that have always separated my pieces from what others build. I see them as extensions of my own creativity and expression.

Chairs are like no other type of furniture – they are both sculptural and functional. They need to be made in such a way as to be sturdy enough to be dragged across a floor while bearing the full weight of a person. A good chair is not only structurally sound but is designed to be light in physical and visual weight, whether it’s plain or heavily adorned. Either way, chairs are the perfect place to blend power- and hand-tool work.

Chairs are like no other type of furniture – they are both sculptural and functional. They need to be made in such a way as to be sturdy enough to be dragged across a floor while bearing the full weight of a person. A good chair is not only structurally sound but is designed to be light in physical and visual weight, whether it’s plain or heavily adorned. Either way, chairs are the perfect place to blend power- and hand-tool work.

If you take pleasure from doing everything by hand or machine, I’m not knocking your choice. Woodworking for me isn’t about exclusion – it’s about inclusion. Approach it any way you like, but you may want to give the blended approach a try; you might get more done and have fun doing it.

For more on blended, or hybrid, woodworking you might check out Marc Spagnuolo’s book by clicking here.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Why blended works:

a) It can take half a day to set up a one-time jig and a machine to do a job you can do by hand in 5 minutes

b) it can take half a day to rip to width an 8′ 8/4 hardwood, then hand plan to square and smooth, or 5 minutes to run it through the table saw and jointer.

Now, it depends if you enjoy the work or enjoy the results.

Let’s not forget, in the old days in Europe the apprentice did a lot of the masters grunt work. A master rarely flattened or thicknessed stock.

While I love to use my hand planes as much as possible I almost always use an electric planner for thicknessing, even if I joint by hand.

My goal with hand tools is safety, meaning I am trying to reduce the usage the power-tools I find the most dangerous, mainly the router table and jointer (I use a stop saw). This means acquiring moulding planes, much to the chagrin of SWMBO) and spending more time with the planer and my Stanley no. 6.

Power tools. Electric, water driven, treadle, etc., have been around a long time. Power and hand will always compliment each other. Nice article. Thank you. Ron

Too many people/magazines get hung up on “I’m a hand tool” or “I’m all power” way to much.

Personally I’d rather read about how to build challenging project – like any of the chairs pictured here.

When I moved to Seattle from England I had to dispose of most of my power tools because of the difference in voltage and cyclic rate. So I started a business designing and building custom desks using hand tools. Unfortunately I couldn’t make it pay, because I couldn’t produce the volume needed using just hand tools. The same was true with carved Roubo style folding bookstands I made as iPad stands. It took me a day to make one. Now woodworking is a pleasant hobby, and the rest of the time I design and build databases for a living. If you are in business as a woodworker, you have to use power tools. Even Sam Maloof used a bandsaw.

Sounds like you’re trying to say that you should woodwork in any way that makes you enjoy doing it rather than woodworking like it’s some sort of crusade?? No offense, but that’s a lot of dandy rot! If we follow your ideas that would leave no room for baseless insults! Where’s the fun in that??

It`s them knuckle draggin Neandrethal’s that want to fight. Those of us who are smart just put up some ELECTRIC fence to keep em out of the yard.

Ducks and runs…………………………………………… 🙂

I use a combination of both, and it works just fine for me.

Well said Chuck. I don’t understand battle line on this topic either. When it comes to just getting work done, use the best tool you can use and stay safe.