We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

How to Buy a Bandsaw

This workhorse is one of the four basic stationary tools in most shops, and can greatly expand the kinds of projects you can build.

| A bandsaw can rip, crosscut, resaw and handle curves, angles and compound cuts. This workhorse is one of the four basic stationary tools in most shops, and can greatly expand the kinds of projects you can build.

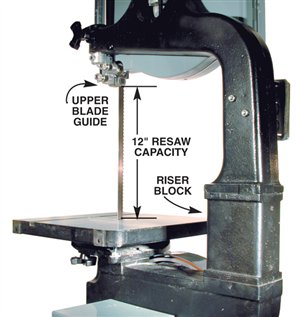

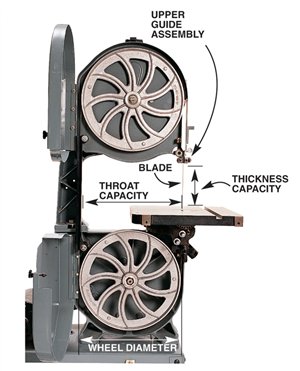

The FamilyBandsaws are sized by the diameter of their wheels. This measurement is roughly the same as the throat capacity, which determines the widest cut you can make (Photo 1). Bandsaws for the small shop have wheels ranging from 10 to 18 in. in diameter, with 14 in. as the most common.

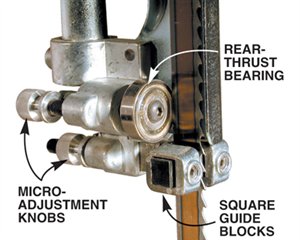

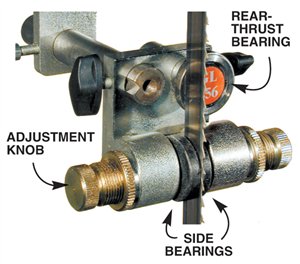

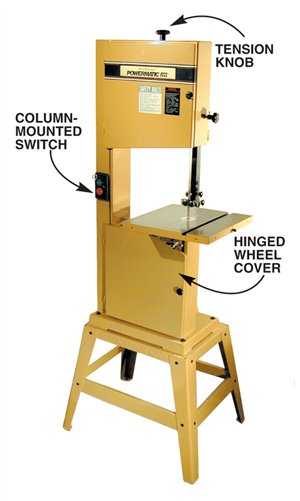

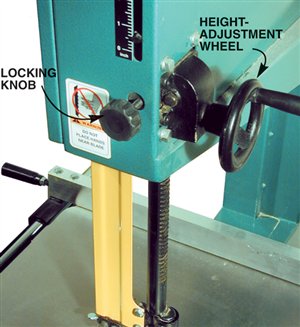

FeaturesWhen shopping for a bandsaw, we suggest you look especially at these features: – Frame: Bandsaws come in one of two frame styles; cast iron and welded steel – Base: A sturdy base helps control vibration as well. For this reason, we favor the closed- and floor-base styles over the open- and panel-base models (Photo 3). – Motor: A 3/4-hp motor is good for most operations, if you primarily cut stock under 3-in. thick. If you regularly cut thicker stock or do a lot of resawing, go for at least a 1-hp. motor. – Riser Blocks: On some 14-in. bandsaws, a riser block increases cutting capacity from 6 – Guides: Block-style guides (Photo 5) are easy to adjust and use. Replacing the stock-metal guide blocks with aftermarket synthetic blocks, such as Cool Blocks, is a good idea. These blocks can be adjusted closer to the blade for better support and enable you to use blades as narrow as 1/16 in. Euro-style guides (Photo 6) are great for supporting wide blades and for heavy bandsaw work, such as resawing. They can be difficult to use with blades less than 1/4-in. wide. – Switches, Wheel Covers and Tensioning Knobs: Column-mounted switches are the most convenient. Changing or checking the blade is quicker with wheel covers that are hinged rather than removable. Tensioning knobs that extend above the top wheel housing (Photo 7) are easy to use and prevent skinned knuckles. – Height Adjustments and Guards: Height adjustment is easiest on machines with rack-and-pinion guards (Photo 8). This setup also keeps the guard from crashing to the table when the locking knob is loosened. Some saws use a spring-loaded, anti-slip guide post to keep the guard from falling when the locking knob is loosened. – Dust Collection: For general use, a 2-1/4-in. dust port hooked up to a shop vacuum will suffice. If you do a lot of resawing, look for a bigger port and hook it up to a dust collector.

Saving Space and MoneyBuy a benchtop bandsaw if you’re really cramped for floor space or on a tight budget. Benchtops typically have less sawing capacity, but are fine for small projects. |

1. Throat capacity determines maximum width of cut. Thickness capacity determines how thick a board you can cut or resaw. |

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.