We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

When I teach dovetailing to a class, one of the common questions is why I saw out the majority of the waste between the tails and pins, instead of chopping with a chisel.

The simple answer is: That’s how I learned to do it, I’m fast at it and coping saws are easier to sharpen than chisels (the last part is a bit of a joke, by the way).

There’s usually some smart aleck in the room who calls sawing the waste a “modern complication” devised in the mid- to late-20th century. To be pure, one must chop.

I’m no purist (except when it comes to reinheitsgebot), but sawing out the waste is not modern. Every time I read an old book that discusses sawing out dovetail waste, I note the publication date. Through the years, that date has been getting earlier and earlier.

Right now, the earliest account I have is 1892 in Thomas A. Clark’s “Workshop Notes & Sketches, Second Edition” (James Thin, Edinburgh). You can download the entire book from Google Books for free here. I haven’t been able to find the first edition of the book, which was published in 1888.

Here are snippets of the original text.

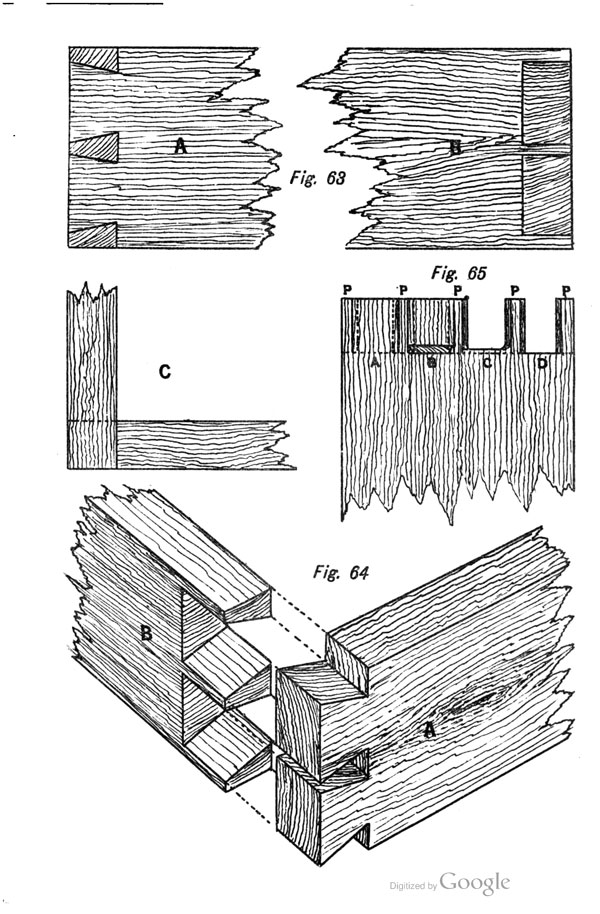

The tenon or dovetail saw is taken to cut down the vertical sides of the pins to the lines, after which the pieces between the pins may be removed. This is done by cutting in with the chisel from both sides, a little away from the line, as at B, or better still, by means of the bow-saw (if it can be got), which has a narrow, thin blade, and if passed down the vertical saw-cut, it may easily be turned round and made to cut along by the line as at c. The holes in the other piece, A, Fig. 64, would be cut out either way, except that the outside ones should be done with the dovetail saw….

When all the pins are marked off, the wood should be fixed upright in the vice, and the tenon or dovetail saw used to cut down the side of the lines, this being done as exactly as possible. The large intervening portions should now be cut out, which may be accomplished, as already explained, by means of the bow-saw, or paring chisel and mallet.

Part of the reason I think that sawing out waste is considered “modern” is that readers look for the words “coping saw,” which is a fairly modern name for a tool that has been around for 500 years. It has been called a “bracket saw,” “frame compass saw,” “Morris saw” and “bowsaw” among other names.

I honestly don’t care how you remove your waste, but sawing it out has been around for at least 122 years. If you have an earlier reference, please post it in the comments.

— Christopher Schwarz

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

An earlier reference to dovetail sawing is “The Mechanic’s Companion,” by Peter Nicholson, 1832. On page 119, he specifically describes the “Dove-tail Saw” which “Is used in dove-tailing drawers.” A free Google copy can be downloaded at:

http://books.google.com/books?id=WGAOAAAAYAAJ&printsec=frontcover&dq=woodworking&hl=en&sa=X&ei=FM7eU7SxPIW58gGU-YCABg&ved=0CIcEEOgBMFE#v=onepage&q&f=false

Real woodworkers use their teeth.

For da foreigners … http://www.wkfinetools.com/wWorking/z_reading/1892-workNotes/0_img-pdf/1892-WorkshopNotes&Sketches.pdf

It gives me an excuse to own a Knew Concepts Fret Saw!

Chris,

The main benefit I find from sawing out the bulk of the waste is that the chopping goes much easier. I saw as close to the baseline as I reasonably can, so the chisel encounters less resistance in the cut and there is less force pushing it back toward the gauged baseline. For me, it is overall faster and more accurate than only chopping.

Thanks for the research. By the way, did any woodworkers of long ago actually cope stuck moldings on furniture? Maybe they did for crown moldings? Did the name of the saw change as it was used for different tasks?

Thanks.

Rob

Chris, you say you’re not a purist. Is that why you kept making benches until you got one as close to what Roubo described as possible? I remember reading you telling about that quest. No tail vise, no parallel guide, planing stop, etc.

My dad introduced me to The Woodwright’s Shop and the episode he called me in to watch had Roy putting together dovetailed pine bookshelves. To cut out the pins, he used a bow saw with a ½” wide blade that was able to go around sharp corners. It was like a magic trick! The blade had a long, tapering kink in it, so you used one end of the blade to cut downwards, the middle part started the corner and the near end cut sideways. One of favourite “go to” moments when I’m remembering my dad.

Following the Reinheitsgebot, means avoiding Weissbier for example as it is a wheat beer.

After watching Frank Klausz turn out dovetail joints without much more than a pair of bow saws and a sharp pencil, I’ve been a convert to sawing out my waste. Chisels are great and all, but if I can use fewer tools and fewer steps, I’m taking that route.