We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I’m in the final stages of setting up a new workshop in Covington., Ky. It’s my seventh (!!) workshop. I could probably write a book on the process, but instead I think I’ll sum it all up here.

I’m in the final stages of setting up a new workshop in Covington., Ky. It’s my seventh (!!) workshop. I could probably write a book on the process, but instead I think I’ll sum it all up here.

During the last 20 years I’ve visited and written about some of the most impressive and modest shops all over the world. From a home shop with a remote-control crane (that shop was nicer than my house) to an unheated, leaky basement with an old desk for a bench.

Both of those shops produced top-shelf work. So a nice shop won’t make your work nicer.

Both of those shops produced top-shelf work. So a nice shop won’t make your work nicer.

Here’s what’s important in a shop (to me) regardless of the budget.

- Flexibility. There’s a good chance your shop will change next month for some reason, and you’ll have to rearrange your bench and machines. Every shop I’ve had has changed multiple times during its lifetime. I’m not advocating putting all your machines on mobile bases (though that’s helpful with some machines). Instead, don’t do anything that limits your flexibility. Don’t bolt things down. Don’t build permanent walls (unless you have to). Keep your space flexible.

- Comfort. Your shop should be climate controlled. Not just for you, but for your projects. Moving finished work from an uncontrolled area to a place with forced heat is asking for trouble. Also, you will be happier if you shop is climate controlled. Second: Do something for your feet. If you can’t afford a wooden floor, buy some mats for animal stalls or weightlifting. (Don’t bother with the cheesy thin foam crap they sell at woodworking stores. It isn’t durable and it doesn’t help much.)

- Light. Do everything you can to get a window in your shop that faces north (or south) and put your workbench near it. Good natural light makes handwork a pleasure. Machines don’t need natural light. Lots of overhead light is what I prefer. And with modern LED lighting you can really control the color temperature of the light. This has been a huge boon for me – getting the right finish color is much easier under 4,000 (K) lights instead of rando work lights.

- Dust collection. I know I’ll catch flak for this, but I have never liked centralized dust collection (or air pressure) for a small shop. It reduces the flexibility of your shop. It clogs. It’s another system to maintain. I have two roll-around single-bag units that handle all the machines. These have zero maintenance headaches. No ductwork. No gates. No additional wiring.

- Water. A slop sink is a huge luxury. You’ve earned it.

- Infeed/outfeed. Because my shop is flexible, I don’t get my panties in a twist about this.

- Wood storage. I think of wood like it’s meat or fresh vegetables. I don’t keep much wood on hand, never have. This is a huge advantage. I don’t have to build a storage area. And I don’t buy wood on a whim, saving money. (Whenever I have, I have regretted it. I either got too much or too little for that “future project.”) Wood hoarding and woodworking are not the same thing. For the wood I do have on hand, I store it in a climate-controlled area.

There are lots of details I could go into about tool storage (build a tool chest) and workbenches (hey, I did write a book about that). But the above principles pretty much sum up what’s important to me.

— Christopher Schwarz

P.S. Hey, if you do want a book on setting up shop, “The Practical Workshop” covers a lot of these issues and is reasonably priced.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

What should the humidity ideally be in a woodshop.?

How can I make a 5-Star review for Chris?

Folks have commented about dust/chip collection a little. I have found that a cyclone in the back room with pipe going to each major tool with gates, and a dust/chip level sensor in my collection barrel, there is no maintenance at all.Remote control on and off. I don’t have plugs, and along with a fine dust collection unit in the main shop, I have very good air quality. Costs money for sure.

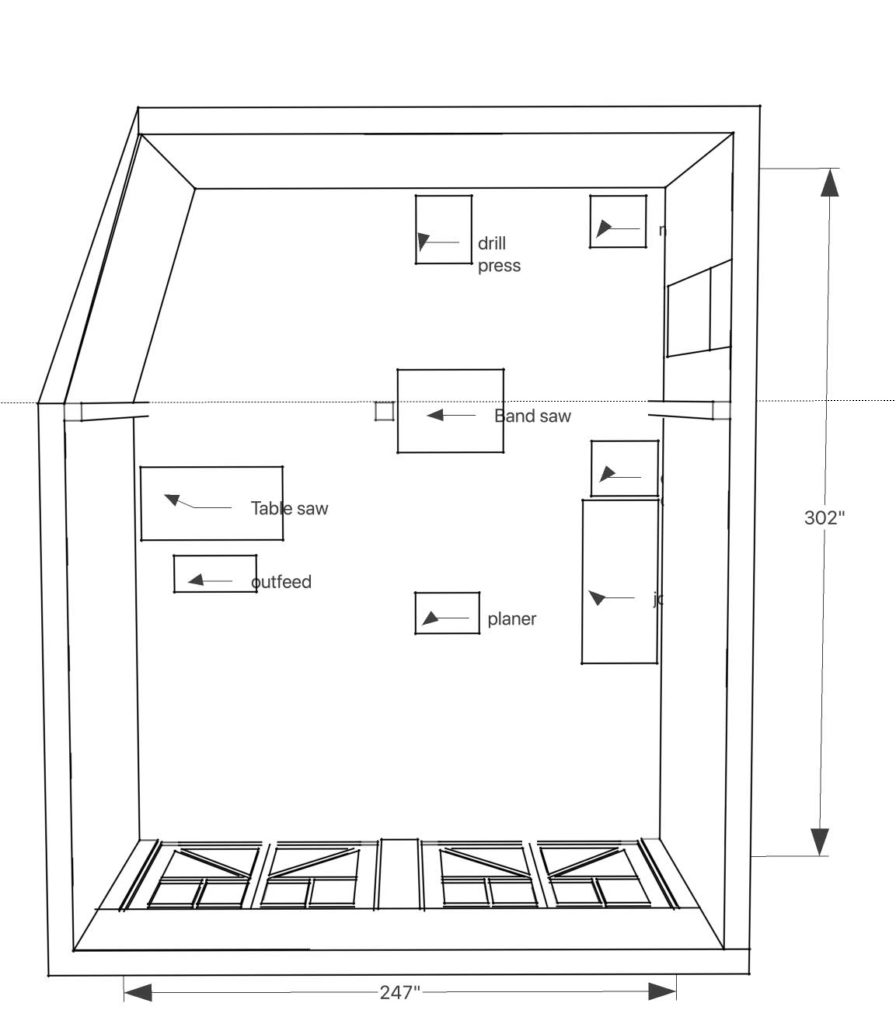

This might be a dumb question – what do the arrows in your diagram represent? Outfeed? Electrical? Where you’ll stand?

For all the dreaming I did for nearly 20 years, I have found all that it took to make we happy was one wall cabinet and a 4×8 sheet of pegboard in front of my 8 foot bench. I had these big dreams but when all was said and done, I use about 60 square feet to woodwork and about another 40 square feet to store wood. Rather than buy the power tools, I just pay to get it S4S’d. I probably use 100 to 200 board feet a year at it doesn’t cost that much to have the lumber yard do it.

No steps!

Hello Chris,

Off topic but I am new to the blog and didn’t know how else to get in touch, so briefly:

I had read that you are working on, (amongst a zillion other things), an english translation of Roubo’s L’Art du Menuisier. Was wondering if that is ongoing or if this translation is for sale yet. I have not seen any banter beyond 2008 or so and can’t find anything more on it.

Thanks;

Jim

BTW…. this is the first time I have ever joined a blog or commented in one so if I have broken some cardinal rule by going off topic, I do so humbly apologize.

Dont see any space for your wifes deep freeze chest 🙂

I agree with tbe your dust collection theory; its easier to move chips 5-6′ with a small collector than 40′ on a large system. I have a old cast aluminum “Cincinnati Fan” blower that works fine. I imagine it was made across the river from you?

The downfall for most shops, is sheet goods and off cuts. Small piles lean against walls and slowly creep inward like a kudzu vine.

Which model is that Grizzly bandsaw?

Always had a basement shop. Not that I haven’t tried (looking for my current home). While it does have some disadvantages (access, natural light, ventilation), it’s just down the steps and hooks into HVAC, insulation, security, water, and electric of the house. Sometimes I wish wish for a big garage door I could open and get fresh air and sunlight. But not this week (-5F – +18F and windy all week). And I don’t have to share with vehicles (or leave them outside). All trade-offs, I suppose.

One of the big drawbacks was getting 20′ of clear space to rip or power plane or joint an 8′ long board.

Do you rip boards on your bandsaw often enough (compared to the table saw) that you are not putting it against a wall?

I’m building a 20×28 shop right now and working on layout. I have my table saw in the same place as you show it.

Humidity has been on my mind a lot recently — my shop space is an uninsulated detached garage, concrete slab, basically metal and OSB walls. Open to the air soffits. No practical ability to control the “climate”. (I’m located in central-eastern KY, humidity levels are 60-85% throughout the year.) Wood kept in the shop is usually right at 12%MC, so I’ve been bringing wood into the (wood-heated) house to dry it out for projects. But that isn’t always practical, so I’m considering building a “kiln closet”, or essentially an insulated corner in the shop heated/dried with high wattage lightbulbs to get wood down to ~5% without cluttering the house.

I’d be curious if anyone had other good ideas on how to deal with high humidity conditions and drying out materials appropriately. I’m kinda over bringing finished projects into the house only to see them eventually blow apart.

p.s. Yes, I have a moisture meter… which helps too…

I am also in the process of building a new shop, my forth. This one will be in the city of Holland Michigan and inside a 3 car garage walling off room for one car and other stuff.

Walled off so that I climate control less space (about 325 square feet) and so that the moisture brought in by a car in winter will stay out of shop area.

A carpet won’t cut it. For the floor I lay 1.5 inch foam insulation board corralled with pressure treated sleepers (2 by 4) screwed into the concrete along the interior edges. On top goes a moisture barrier (plastic sheet) and then two layers of 1/2 inch underlayment. One layer runs east-west and the other north-south. They are screwed into each other. The foam and plywood will support all the heavy tools, cushion my feet, keep my feet warm in subfreezing temperature, and protect any tool that falls from hitting concrete.

Our monthly average temperature varies from 0 F to 90 F and average humidity ranges from 50% to 90%. I will put in a 1/2 or 3/4 ton mini-split to control the climate.

It has warmed up to a balmy 15 F, so I will put more work into the new shop. Adding insulation now so that I can temporarily heat it while I work on the rest of the shop construction.

Chris, I agree with your other points but I am conflicted about dust control.

There is undoubtedly no vapor barrier under the concrete floor. A shop that I had earlier in my life also did not and I was constantly fighting surface rust on bare metal surfaces. I found furniture wax worked well to impede rust, but had to reapply often. I will be interested to hear about your experience with this going forward.

Hi Chris….John from UK

let me say…..all with a light heart not critical…….”climate control”. Put a coat on or take my shirt off …..open the doors or stuff a rag at the bottom……..”Wooden floor”. Scrounge a second hand carpet??

Would love the size…….extra woodstore…..what a luxury

The very nice painted 2 pair of double doors…..will those hinges hold up doors……. and opening onto pedestrian path……….all light hearted observations…..enjoy your work shop……..best John uk