We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

We all have junk in our shops that we don’t use or no longer need. My junk is sometimes a bit unique, but it’s junk none-the-less. I’m cleaning out my shop, making room for more junk and I’ll probably drop some on ebay. I won’t post links to my auctions because I think that’s icky. But not all junk is created equal. I have 4 sets of old chisels I’ll auction off but I wanted to give you first dibs. The prices here will be either the reserve or starting prices.

We all have junk in our shops that we don’t use or no longer need. My junk is sometimes a bit unique, but it’s junk none-the-less. I’m cleaning out my shop, making room for more junk and I’ll probably drop some on ebay. I won’t post links to my auctions because I think that’s icky. But not all junk is created equal. I have 4 sets of old chisels I’ll auction off but I wanted to give you first dibs. The prices here will be either the reserve or starting prices.

These may not be reasonable low cost solutions to your chisel needs. These are VERY old chisels after all. But I learned a great deal from examining and using my old chisels. They exhibit a few features that no chisels offer today for reasons I do not understand. I’ve not been particularly influential when it comes to chisel design. Maybe you will have better luck than I have had.

These old chisels are square sided, or at least they appear to be until you look closer. Their sides are ever so slightly beveled back from the back of the chisel. So too are their widths. 1/2 inch chisels were only 1/2 inch when they were new and only at the tip. Their widths taper back from their cutting edges. They are also remarkably thin. In a world in love with cold chisel-esque Stanley 750 pattern chisels, these chisels appear to be toys. Most are or were less than 1/8” at the top of the bevel. Many may have been closer to half that. We would classify them as paring chisels today. But make no mistake about it, these were firming chisels designed for cabinetmakers and joiners, not the carpenters Stanley sold their 750’s to. What is it we don’t understand about chisels, and their use, that causes us to seek ever punch-like chisels made from miracle steels? Though shortened from several lifetimes of work, tempers possibly shot, these tools were usable and I wager can be again.

Steel from this period is interesting as well. These tools were likely made much like Japanese swords. They were hand forged. The process decreased the grain size of the steel and reduced the size of the impurities, resulting in stronger steel. It has been my experience that such chisels are easy to sharpen and take a fantastic edge. Edge retention varies tool to tool, but can be generally overcome by watching the performance of each tool, and honing frequently. I have had some limited success reheat treating old chisels. But my sense is that using chisels is a skill, not a simple matter of finding a superior metallurgist. Toolmakers must do this. And they get a lot of press. But our job is to develop the skill of using.

The condition of these tools varies tool to tool. There should be at least a few tools in each set that can be reworked and used effectively. Pitted backs are common. Remember that not every pit needs to be removed from a chisel back for it to cut. You just need to watch the ones closest to the edges.

Please notice the many small sizes listed. Perhaps I haven’t been following the antique chisel market closely, but it seems uncommon to see so many sizes less than 1/2”. And herein lies a tip for all of you. I think it’s advantageous to have 1/16″ increments under 1/2″. I also think it’s helpful to have full and bare sizes around 3/8″ and 1/2″. I use the 18th century terms “full” and “bare” (abbreviated f and b) to indicate the actual size of the tool is more (full) or less (bare) than nominal. Old chisels are rarely dimensionally accurate.

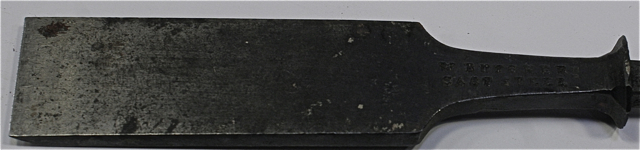

Set 1: 11 pcs W. Butcher Sheffield $75 shipped CONUS

I believe these to be early 19th c tools. Butcher was in business from 1819-1950. The smallest has what I believe to be it’s original handle. All the rest are handless. Recommend patterning handles off of Seaton chest handles. Recognize that they change shape and size according to the chisels width.

Sizes: 1/4b, 1/4f, 3/8f (rusty corner may be unusable?), 7/16 (back badly out of flat),1/2f (short), 5/8 (rusty corner) 7/8 (badly pitted likely unusable), 1, 1 (extra may be ground down to make up for 7/8) 1-1/4, 1-1/4.

Despite my harsh critique of the condition of these tools, I have restored chisels in this condition and worse. At this time Butcher was making these tools from solid ignots of tool steel. Removing a good bit from their backs will only make the tools edges more like they were when they were longer. Only possible down side is the need to reheat treat. I would be inclined to use them first and learn as much as possible about them before resorting to that. That said, this is easily done now that the handles are off. I did a batch of old molding plane irons in preparation for WIA in about 2 hours start to finish. Just please be cautious. It’s possible the chisels once resurfaced will get better due to the removal of the decarbed layer.

Set 2: 11pcs W. Butcher Sheffield SOLD

These chisels also appear to be early 19th c tools. They are obviously handless. They are in generally better condition then the set above. But looks can be deceiving. Increased price is more a function of consistency of length and better distribution of sizes. Tempers could be shot and I wouldn’t know.

Sizes: 5/32, 1/4, 3/8f, 7/16, 1/2F, 5/8, 3/4f, 7/8, 1, 1-1/4, 2 (beautifully thin- I love a big thin chisel)

Set 3. Greaves Sheaf works 11 pcs SOLD

This is a newer, Victorian or Edwardian set of firmers with what appear to be many original handles. Only regret is that the set is missing 1/2 and 1” tools. What attracted me to this set was that Sheffield makers continued to make early 19th c style chisels for easily 100 years. How is it that a pattern that lasted that long, and serviced so many professional hand tool woodworkers is no longer available? Greaves is a good name and these chisels are near full length and beautifully thin.

Sizes: 1/8b, 5/32, 3/16f, 1/4f, 5/16f, 3/8, 5/8, 3/4b (pitted), 3/4b (rusty, condition unknown, but long), 7/8, 1-1/4

Set 4: 5 pcs W.Butcher carving chisels SOLD

This is a newer, possibly Victorian set of what I believe to be a cabinetmaker’s carving gouges. A great deal of (bad Victorian) cavring can be done with these few tools plus a few sharp firmers. These are much lighter than firming gouges, but it’s possible they are firming gouges. I believe 4 of them are the original factory handles. I believe these can all be put to right with a little elbow grease.

Sizes: 1” #3 (light pitting), ½ #3 (heavy pitting), 5/16f #3 (heavy pitting), ¼ #5, 3/16 #5 (light pitting).

Terms and Details: CONUS shipping is included with all sets. First email in my inbox making clear that you want to purchase gets it. If you have questions, this may not work out for you, but it’s worth a try. Payment is whatever works for you. I can issue paypal invoices or accept personal checks. If you get the tools and hate them, regret the purchase, you can send them back for a refund. You pay return shipping back to me.

For those who aren’t interesting in buying these tools, I hope you enjoyed this blog post just the same. This is a subject I feel strongly about. I love using chisels and I feel this is a subject we need to discuss more often. I feel that as a community of users, we aren’t where we could be with respect to chisels. I hope this post stimulates your thoughts regarding these important tools.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

what the letter stand for after the size….i miss your story line in pm

Adam,

There is a pretty big difference between carving gouges and firmer gouges.

Adam,

Just received April issue of Popular Woodworking. Your absence was noted. Arts & Mysteries was always my first stop. I hope this is a short term thing.

Regards,

Bill

I also have an amazing amount of “junk” that I have yet to part with. You have inspired me to do some clean up!

Thanks!

Chris Mobley

http://www.cmobleydesigns.com

Adam, While I have no interest in purchasing any of the chisels (my wife told me i didn’t) I found this very interesting. The history of hand tools fascinates me.

A piece on making handles (using hand tools only) for chisels with a tang would be interesting.

I seem to remember you making a handle for something (boy, how’s that for being specific) at WIA in Cincinnati (Covington) last year.

btw… really enjoyed your presentations at WIA.

Thanks, Cosmo

Having trouble editing my blog. Carving tools are sold.

Some tempting items there. One question…what is your eBay seller name so we can keep an eye out for more goodies?

Thanks, Bill