We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

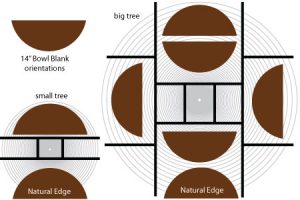

My turning ability is bound by my lathe – it has a maximum diameter capacity of 16”. That means all my accessory tools, such as my hollowing system and 50cc 20” chainsaw, were acquired because they are designed around those size limitations. The largest bowls I make with these constraints are in the 14-15” range.

For years I used fallen trees with a 20” diameter as raw material. By the time you remove the bark and cambium layers, you have a blank that shows off both sapwood and heartwood in the same finished piece. You have control of the balance of sapwood and grain but other than that you get whatever the material possesses. If there are bark inclusions, spalting or curl, the juxtaposition from other areas in the same bowl is dramatic.

For years I used fallen trees with a 20” diameter as raw material. By the time you remove the bark and cambium layers, you have a blank that shows off both sapwood and heartwood in the same finished piece. You have control of the balance of sapwood and grain but other than that you get whatever the material possesses. If there are bark inclusions, spalting or curl, the juxtaposition from other areas in the same bowl is dramatic.

Customer comments on bowls from this size material are always about the beautiful wood. Not the design.

I’m confident in myself nowadays to say, “Big Wood is Better.” That same 50cc 20” chainsaw bar can process a log up to 40” diameter safely. You stair-step multiple crosscuts from opposite sides to work your way through. It’s best to create a kerf across the top, cutting deep enough to engage the spikes but not bury the tip. This allows you to line up the cuts from opposite sides. Then it’s a matter of engaging the spikes and rotating the bar to the point right before the tip engages, then repeating from the other side until you work your way down.

Then cut bowl blanks from those 18”-wide crosscut rounds. Other than the requirement of removing the pith you have control of all aspects of the bowls, not just the grain direction. Careful analysis will allow you to find virgin material or isolate elements such as curl, spalt, inclusions or sapwood. You have more options.

Plus the grain is straighter so drying induces less warpage. You can rough thinner to speed drying.

You’ll also get more comments about your designs as well as the material.

Large trees such as this can be found. My preferred place is from professional arborists as they have the machinery to load big logs into my truck. I understand some charge $20-$40 per ton, but I usually get mine for free as a courtesy to the homeowners where the trees come from. Also, I return a bowl or two to the arborist they can pass on to the customer.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.