We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Responding to my post last week on the demise of woodworking clamps made in the U.S., a few readers pointed out that the well has not completely dried out. Yes, we have probably lost the big names in casting, forging and milling of clamps, but a few smaller manufacturers have survived, in addition to new makers who have released some interesting stuff in the last few years.

A few years ago we bought a 10” Milwaukee Tool and Equipment Co. woodworking bench vise. This is a really strong work horse, reliable and impressive that is used by our students day after day.

Milwaukee Tool and Equipment Co. – not to be confused with the Milwaukee that makes electric, battery powered and other tools – is making vises for both metalworking and woodworking, they also make C-clamps and have been in business for more than a century. As far as I know the only woodworking supplier who carries their vises online is Tools for Working Wood. To find out about their entire line of vises and other clamping tools check their website.

Dubuque Clamp Works makes its Universal Bar Clamps in the USA. These are medium-duty bar clamps made from aluminum. I have two of their clamps and they are really handy and strong. The company’s other domestically made clamps are: Wooden Handscrew Clamps, and Miro Moose Cam Clamps. The latter are wooden clamps for delicate or sensitive clamping such as in a luthier’s work.

Clamp Manufacturing Inc makes the Kant-twist clamps. These clamps have pivoting jaws which allows them to adjust to un-parallel surfaces

The JackClamp is an innovative American clamp system that claims, as suggested by its name, to be the Jack of all clamps. Check out this site to see it in action.

Cleaning and Oiling Your Clamps

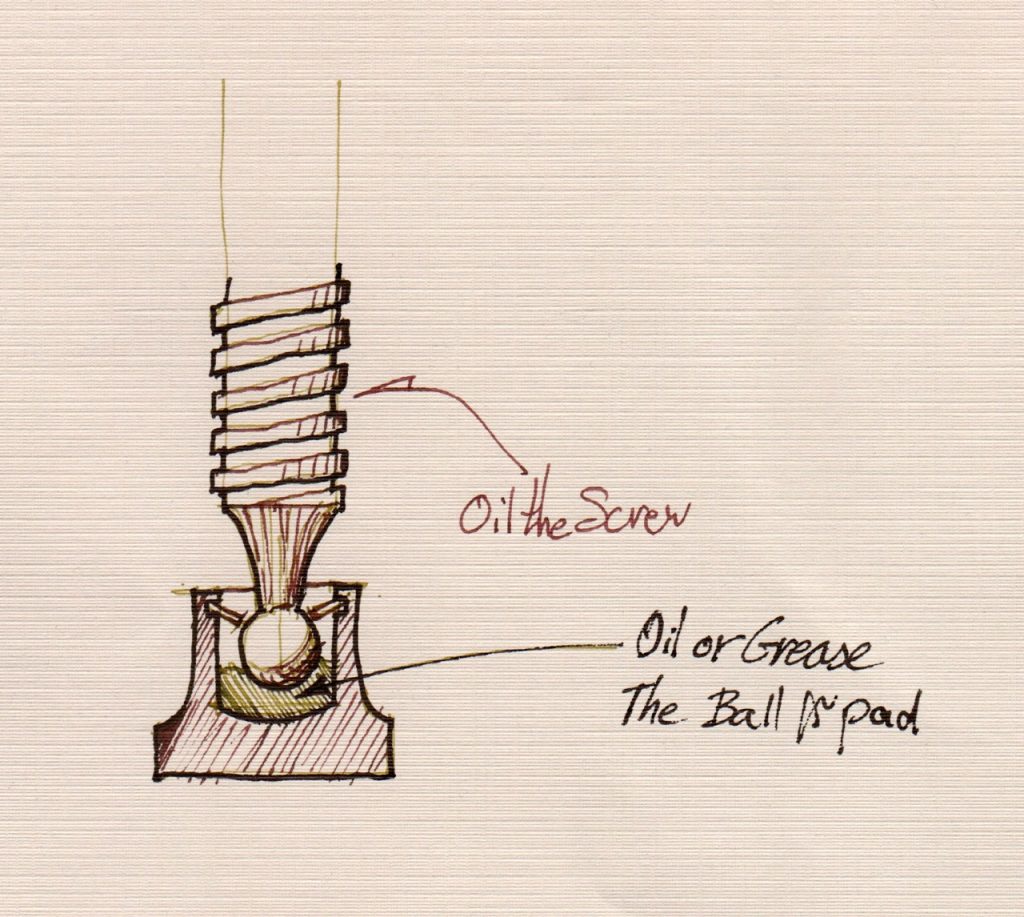

Lubricate your clamp pads to extend their life and prevent the ball from pushing through the flat surface of the pad.

When I buy new clamps, find second-hand ones in garage sales or (believe it or not) even in a “Free stuff” box on the side of the road, I make sure to clean the screws and oil them before use.

Rusted screws can be cleaned with Scotch-Brite pads, a stiff brush or steel wool, followed by a rag moistened with mineral spirits. After this, I oil the screw, the ball at the end of the screw and the clamp’s socket pad. It is very important to lubricate the ball and socket pad; it will reduce friction during tightening, which means longer life for both ball and socket. Lubricating these will also reduce the tightening torque needed to achieve the necessary clamping pressure.

If you fail to lubricate the ball, it will at some point start to erode the socket and push through it, as seen in the pictures below.

Replacing a Worn or Missing Socket Pad

Did you know that clamps that have lost their pads can still be rehabilitated? When I began teaching in my school I discovered a cache of crippled “C” clamps . I opened my McMaster catalog and ordered replacement pads in four sizes. These pads are the same pads that used to be on the older Pony clamps. Made by Jorgensen, they are hefty and will clip onto the ball at the end of the screw, and will hold onto the ball via the help of an integral retaining washer, so no banging or hammering is needed. After receiving them, I put a dab of grease in the sockets and placed them over the orphaned balls; grease is better than oil for this purpose but can be more complicated to apply.

Our old C-clamps lost their original pads at some point but gained new ones that work even better.

As I mentioned in my previous post, it seems like Jorgensen is no longer making clamps and parts in the U.S. Plus, in the last few years the company has skinned down the design of their heavy-duty pads, making them less robust and irreplaceable, so who knows for how long we will be able to order the older snap-on pads.

Jorgensen’s replacement pads. They can fit over the ball of clamps made by other manufacturers, too.

An orphaned socket pad of the “pressed on” persuasion

By following these simple cleaning and lubrication steps you will make both your clamps and your wrist joint much happier.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.