We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

We have iron planes and wooden planes. Iron vises and wooden ones. Iron clamps and wooden ones.

So it shouldn’t come as a shock that you can have a wooden holdfast. But it does.

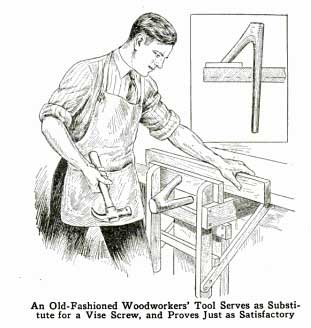

Carpenter and researcher Jeff Burks passed me this clipping from a 1930 edition of Popular Mechanics, which discusses the “barilette,” which is a wooden holdfast. Check out the text here:

“The ‘barilette,’ which is little known on the modern workbench, is an exceedingly helpful tool, and a valuable aid for holding boards flat on the bench while working them. In its simplest form it is a fork of wood or iron, one leg of which is dropped through a hole in the bench top, as shown in the detail, while the other leg rests on the work. A sharp tap on the head of the fork wedges the barilette and holds the work firmly. Iron barilettes are sometimes fitted with a refinement in the form of a screw-tightening arrangement, which, while adding to the cost, does not greatly increase the usefulness of the tool. This form is that known to wood carvers as a ‘hold-down.’ The writer prefers a wooden one, made from the tough fork of a tree, to any form of iron tool, as it is lighter to handle and lower in cost. The longer limb should be about 1-3/8 in. in diameter, and the holes in the bench made with a 1-1/2 in. bit. The larger drawing shows an unusual application of the barilette, in which it is used as a substitute for a screw in the bench vise. A tap on the end of the barilette tightens it, while an upward tap below the outer end loosens it. This contrivance provides an instant grip, which many quite expensive vises fail to do in practice simply because their parts cannot work freely enough.’

— S.E. MacNair, Rio de Janeiro, Brazil. Popular Mechanics, November 1930, page 858

If it weren’t dark right now, I’d head out to the backyard with a pruning saw to hunt me up a barilette. Our neighbors have a gnarly locust tree that could be a target-rich environment for barilettes.

If there are readers out there who have experience with these contrivances, speak up. We’d all like to hear about your wooden holdfasts.

— Christopher Schwarz

For more on this subject, check out “The Mystery of Holdfasts” digital download by Robert Lang.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

It works! Heres some pictures of the one I made: http://imgur.com/a/1XNwe

It’s a piece of Oak (Red, I think) fire wood from some trimmed branches. Of course some bugs got to it and there’s a tiny bit of spalting but even with all that, this thing really holds fast (sorry couldn’t help myself…). I’m using it only on my sawbench as I don’t yet have a proper bench that could use holdfasts. The holdfast is about 1 1/8th inch in diameter. I didn’t bother making it perfectly round though and it tapers a bit towards the end but neither seems to matter. I used a hatchet to chop a bit of wood off one side to bring the diameter down. It started about 2 inches wide.

It’s about 8 inches long and has around 2 1/2 inches of reach. It’s perfect for the sawbench. I’ve used it a bunch in the week since I made it and it hasn’t failed yet. I am thinking of filling the holes with some epoxy or something, though.

Thanks Christopher!

I would try this and may do so. Would like to see a pattern for the deadman, and hear suggestions for species of wood best suited for the barilette. I encounter alot of rhodendron trees where I hike in the mountains that seem to be stronger than other woods and may try that for the barilette. Of course the locust is a very hardy wood but tend to grow straight up with little to any forking.

I think it would be worthwhile to wrap the crotch area tightly with leather or strong twine to strengthen it. Especially if you plan to make one to fit a standard 3/4″ hole.

Reminds me of two tools Roy Underhill likes to point out.

One, a wooden jack plane where a replacement handle was fashioned from the crotch of a small tree, very similar to the illustrated holdfast but just a sawn portion of it.

Two, a cant hook where the mortise to accept the curved iron hook was chopped through a knot. The grain flows around the mortise on each side, maintaining the strength of the pole.

I’m sure he’s the school shop teacher with that tie. But isn’t sliding deadman a double oxymoron?

Thanks for sharing the illustration, Chris. I’m a baby-boomer sucker for those mid-20th-century gems. Deltagrams perfected the look. My favorite setup is a guy, in a tie, working over his lathe while his wife, wearing her Leave-it-To-Beaver house dress and pearls, looks on with admiration. That’s the way I run my shop. Right.

I’ll wait for you to try it. I am a bit reluctant to drill a 1 1/2″ hole in my bench just to see.

But, perhaps it would be awesome to use on a sliding deadman! I think I’ll try it.

Well, It couldn’t hurt. The relaxation of the dress code at work has led to a general demoralization of society in the last century.

And yes, I get the meaning of malapropism.

Hmmm… Do you have to wear a necktie to work with one of these?