We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I’ve drawbored hundreds and hundreds of joints since 1999, mostly on workbenches I’ve built for myself or with students. That doesn’t mean I know jack buddy about drawboring, as last weekend proves.

I was in Oak Park, a suburb of Chicago, for a Lie-Nielsen Hand Tool Event and staying with a friend. Let’s call him “Narayan.” I was staying with “Narayan” during the show to save hundreds of dollars in hotel fees and to force him to open his 23-year-old Pappy Van Winkle bourbon.

In “Narayan’s” basement were the parts to a workbench that I had made for him a week earlier while I was teaching at the Marc Adams School of Woodworking. In addition to drinking his Pappy Van, I really wanted to get that bench assembled before the parts cast too much.

First order of business: Drill all the drawbores.

Second order of business: Make the 1/2” drawbore pins from oak.

“I don’t have any oak,” said “Narayan.”

“What? Isn’t this Oak Park,” I replied. “And you don’t have any oak?”

So we drove out to the most messed-up home center store ever, a suburban Menard’s. It had a huge slide that deposited you in the candy aisle. And employees who were helpful but ignorant.

“I need dowels,” I told the lumberyard employee.

“Dowels?”

“Yeah. Long sticks of wood that are round in section,” I replied.

“Yo, we got dowels?” he called to another employee.

“Dowels?”

Soon enough “Narayan’s” 5-year-old son located the dowels for us. And then we encountered a crisis. They were out of 1/2” white oak dowels. They had only 5/8” dowels. I’d not used 5/8” dowels for drawboring, but we didn’t have much of a choice. So we cashed out.

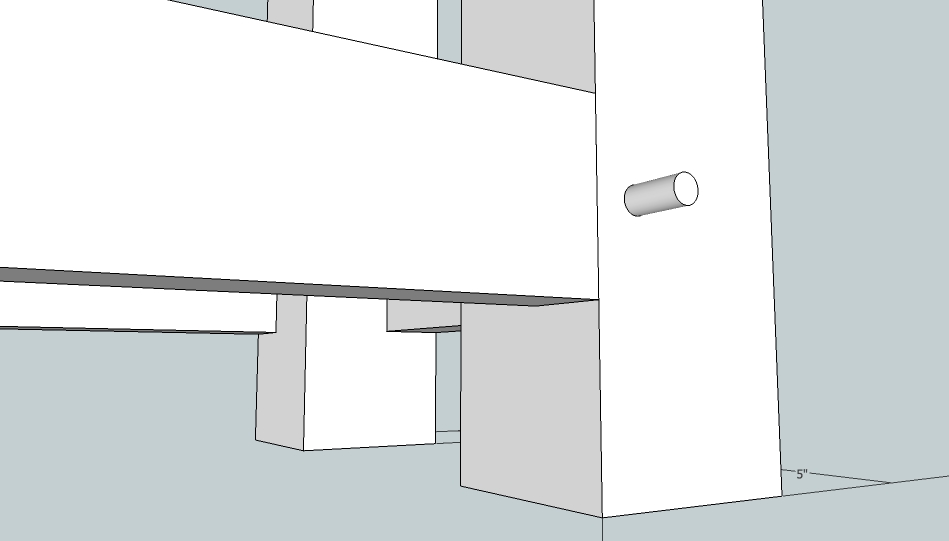

We bored the holes and used an offset that was strong – between 1/8” and 3/16” in Douglas Fir. We pointed the dowels so they tapered to a point over 1-1/2”. We waxed the dowels with paraffin – a timber-framer’s trick.

But when “Narayan” began beating the dowels into the drawbore holes, I almost couldn’t watch. I’ve split 1/2” dowel stock. Heck, I’ve split 1/2”-diameter rived stock.

But the 5/8” stuff was different. It sounded different when you hit it. It went in with confidence and navigated the offset holes like nothing I’d ever seen before. And when it was all done, I was seriously impressed with the results.

So for now I am switching to 5/8”-diameter pins for drawboring bench joints.

— Christopher Schwarz

OK, you want to read about workbenches? I’ve got seven years worth of my writing on workbenches here on this site, all free. Want to get started? Click here.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I just want to know how the pappy’s taste.

So… what you’re saying is that size does matter.

Darn, us boutique (available, Iowa, Illinois, the coasts) are rye drinkers are out then. Consolation: I have a great source for white oak, and armed with a Lie Nielsen dowel plate…

Don’t have the math at my finger tips, but would suspect that stiffness is a cube function of the diameter.

And yes, there are definite rules as to peg size and its relation to placement on the tenon.

Would have to go hunting to find written references. It is a big deal in timberframe work.

At some point I’d be worried that the drawbore peg would be stronger than the short grain at the end of the tenon and would just split it out rather than bending through the offset.

Anyone had this happen in a bench-scale assembly?

You graciously left out the part where “Narayan” cut one of the leg tenons a smidge short then fixed it with a vat of “epoxy”.

Chris,

Do you have a rule of thumb for edge distances in drawbored joints? If you use a 5/8 dowel, what would be the distance from the edge of the hole to the edge of the board. And I guess the question is for both the tenon and the cheeks of the mortise.

http://www.youtube.com/watch?v=ngaUBXwzza4

’nuff said

First, I would like to apologize for the traumatic experience at Menard’s. Unfortunately, it’s a very popular store in these parts so it won’t be going away any time soon. Second, I learned that to have a bench personally assembled by “The Schwarz” only requires some good liquor and the challenge a pile of bench parts presents 🙂

I put my work bench together the week before last and I am proud to say I used no glue on the entire assembly and it is un moveable. God Bless the Drawbore pin

I never thought about it, but really, why I am I not getting a steady supply of oak for every day I work in Oak Park? Seems only fair.

Firstly, I’m glad to find another bourbon lover here in the wood pile – I’ll have to square you away when we happen to bump into each other. And secondly, the point of the article is lost on me – why is 5/8″ dowel stock better? Is it going in 1/2″ holes? Or did you split it down to something like 1/2″? I’m lost. Thanks.

I got 99 dowels but 1/2 ain’t one.