We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

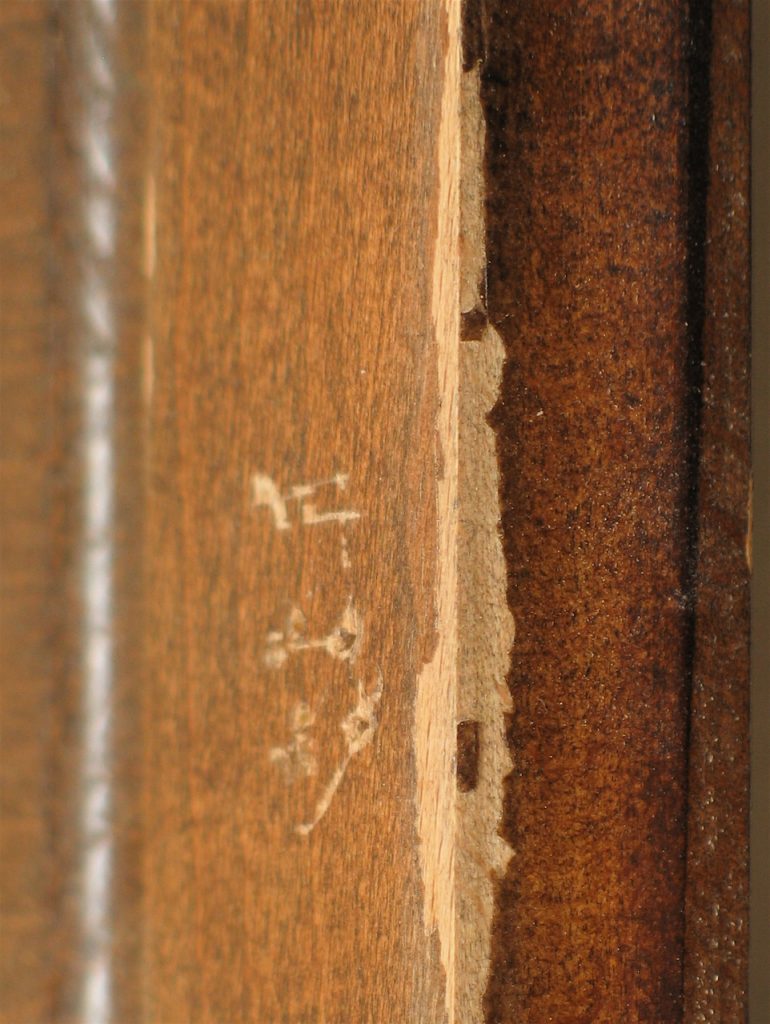

Sharp edges should be softened by a light sanding so this doesn’t happen.

Sometime early in your woodworking career you probably learned that you were supposed to sand sharp edges to soften them, or as I learned, to “break edges.” You may not have been told the reason for doing this, or you may have been told a reason that isn’t true. The real reason is a little obscure, so I can understand that you could conclude that sharp edges dent easier than rounded edges – that avoiding the dents is the reason.

But this isn’t the reason for this rule. What you’re really trying to avoid is “fat edges” when the finish is applied. The problem with sharp edges is that a film finish doesn’t flow over and bond to them well. Instead, film finishes, meaning finishes that dry hard so they build, pull away from these sharp edges and lump or ridge next to them. This leads to premature peeling.

If you don’t know the rule of “breaking edges,” you may have experienced the peeling and not understood why it happened. You don’t need to sand much to avoid fat edges, just a couple of light passes with medium-grit sandpaper.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.