We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I’ve worked out of a traditional floor chest since 1997 when I built my first cover project for Popular Woodworking Magazine. It’s not that I’ve always been monogamous, however. I’ve tried all manner of wall chests, tool racks, rolling cabinets, soft-sided bags and suitcases as ways to contain, protect and limit my tools. But I have always come back to my floor chest.

Here’s why.

Nothing else gives me the same level of protection for my tools. Nothing keeps them as well organized but accessible. And nothing else is sized so perfectly to contain a complete (but not insane) collection of hand tools for building furniture.

Let’s discuss each advantage individually.

Protection

Even if you live alone in the mountains with a shop that is guarded by three Chinese spirits, your tools need protection. Not from thieves, necessarily, but from dust, rust and other aggressive tools. (Oh, and if you have children, add them to this list, too.)

If your tools are dusty, they are on their way to being rusty. Common dust contains salt. And salt attracts water, which wants to react with the iron in your tools to make baby iron oxides.

Consider this: I live in a river city. My shop is in a basement. The relative humidity is regularly more than 90 percent. Yet, I don’t have a rust problem. Why? I wipe the dust off my tools with an oily rag and put them in my tool chest. Then I shut the lid at the end of the day.

If I spot a rust patch on a tool, I immediately remove it with a rubberized abrasive (such as the Klingspor Hand Blocks) and wipe the bare metal with oil.

It does not matter what oil you use. What matters is that you apply it regularly and apply a thin layer. Do this and you will never encounter a problem with finishing – even with water-based finishes. Promise.

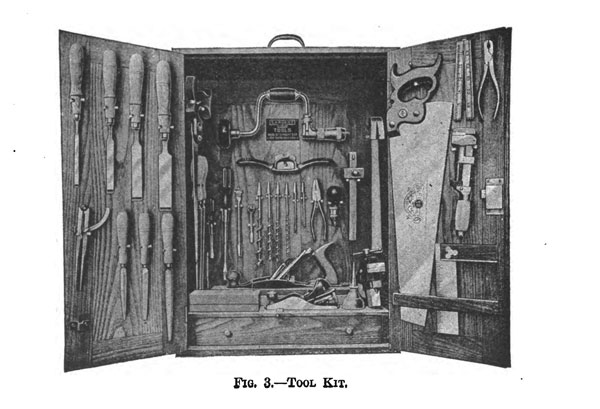

Sometimes tools need to be protected from other tools. You wouldn’t throw your chisels into a drawer filled with rasps. Build racks in your chest for your chisels. Put your rasps in tool rolls. Protect tools’ cutting edges with plastic edge guards or homemade wooden ones. Retract the irons into your plane bodies. That is enough.

Yes, sometimes your try square will ding the wood on your winding sticks. That’s an acceptable toolbox ding in my book. What I don’t want is for a chisel’s edge to get chewed up when it encounters my trammel points.

This sort of protection is closely related to the organizational principle used by most tool chests, which is to say, they are pretty unprincipled.

Organization

Tool chests are common finds at antique stores. And almost of them share the following characteristic: They contain few, if any, tool holders in their trays. Yes, many chests have a tool rack somewhere. Yes, many have a wall in the floor to separate the moulding planes from the bench planes. A good number of them have sawtills of one kind or another.

But when I see a historical tool chest that’s as well organized as the H.O. Studley chest, it will be the second chest I’ve seen like that.

Most chests have interior trays that might have one or two walls. Most of the trays I see have none. So should you simply pour all of your tools in there in a heap and shake them around? Hardly.

Tool chest organization is more like a loose friendship than an arranged orthodox marriage. Every tool has a home in my tool chest. And while I might move a tool to another location in my chest, the time to make that change verges on the geological.

My marking knives and pencils have always been in the top right-hand tray against the right wall. The block plane is on the left wall of that tray. My other important tools are arranged in the middle. I could honestly walk up and snatch my 6” combination square from my chest while blindfolded.

But things can change. During the last five years my compass has migrated to sit on top of the case for my trammels. That just makes sense. This familiarity breeds speed. I can snatch tools and put them away without thinking. This leaves me more time to think about the project.

So why not use little tool holders in the chest that protect and organize the tools? I tried this. Several times. Here’s the quick answer: Tool holders take up unnecessary space. They look all uber-Felix Unger, but they decrease your storage capacity and reduce your flexibility. This isn’t my opinion. It is an answer that was revealed to me by working out of historical chests and asking: Why are chests built like they are?

The Limiting Factor

A traditional tool chest that measures 24” x 24” x 40” will hold everything you need to build furniture by hand – and then some. You don’t need six bench planes. You don’t need a full set of hollows and rounds. You don’t need four sets of different kinds of chisels.

Once you try working leaner, I think you’ll naturally resist buying additional tools. Not only will you have to carve out space for new acquisitions, but you will have one more tool to care for. When you have a glut of tools, many of them become and remain dull. Part of your time in the shop will be searching for a tool that is sharp and well-set from among several similar tools.

If you have only one smoothing plane (and I do), you can darn well bet that you will always know what state it is in (I do).

Honestly, this aspect of my chest gives me great psychological relief – something I never expected from a box of wood. When I encounter a charming new tool, I think: Does it work better than my current birdcage awl? If so, I’ll consider upgrading – if I can break my psychological bond to the old tool and prepare myself for learning the peculiar ins and outs of the new one.

Think of your tools as software. Do you need 10 different versions of Microsoft Word going back to back to Word ’98? Do you need six word processors? Or do you need one program that suits your work right now?

Sure, it’s fun to experiment with different tools. That’s part of the journey. But I encourage you to try different tools at shows, at clubs or at woodworking stores. Ask for others’ opinions, but nothing beats holding the tool in your hand and making it eat wood.

Finally, I think you can make a tool rack or wall cabinet that adheres to the above ideals that will work great for you. We are all clever monkeys, after all. But I keep coming back to the floor chest because it already has been thought through. It has been perfected. And it has been simplified to the point where I don’t have to think about it.

So instead, I can think about the piece of furniture on my workbench.

— Christopher Schwarz

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

“Once you try working leaner, I think you’ll naturally resist buying additional tools. ”

If nothing else stuck with me from reading “The Anarchist’s Toolchest”, this did. Seriously. Up until then I’d been buying tools with very little reason, just because they looked neat. I finally built a chest (a Dutch-style chest, because my currently workspace is six feet square, and I really couldn’t afford to give up a third of the width to a tool chest), and started working out of it, and… well, the urge to buy duplicate tools is gone. I’ve replaced a few with specimens in better shape since then, and added some things I just plain didn’t have an equivalent for (the beading plane and tenon saw come to mind…), but no more duplication. Nope, not tempted by that #5… I’ve got one, it’s in good shape, and it works. Why do I want another?

(Ok, ok… the $40 #7 in near perfect condition nearly got me. I mean, really… it needed to be sharpened and polished, and that’s IT. Maybe the tote could have used some new polish, but it didn’t really need it to be useable. But I’ve already got a jointing plane, and while it’s imperfect, it works perfectly well, and it’s inherited, so on to the next booth I went.)

So I and my bank account both thank you.

I love the concept but still subscribe to ” He who dies with the most toys wins”.

There may be words of wisdom in not building a niche for each tool… My main chest for planes is “stuck” the way it is, adding a new plane means re-doing the whole interior. Giving me ideas on better tools storage…

Great article! Using tools, including tool chests and benches is the best way to learn to use them. Although I don’t do as much work as you do, I have four antique floor chests, two of which are in my shop and filled with tools. The dilemma I’ve had is that none of the four have chisel racks. I have one leather roll that holds a few chisels, but I’m always worried about all the edge tools I have in the chests stored in the tills, including chisels, brace bits, plough plane irons, and marking knives. Making boxes for these things would help, such as a Jennings bit box, but it also seems like it would waste space in the chest. Maybe I have only carpenters’ chests, and they didn’t have many chisels? Maybe leather rolls are the way to go? Any thoughts?

One of my chests I purchased is a large carpenter’s chest that included all the bench and moulding planes, some various other items, and a set of several T-handled augers. There is a divided section for all the moulding planes to stand on end at the back of the chest on the bottom, but all the other bench planes sit in the bottom of the chest, along with many other items including the augers. I can’t figure out how anyone would work out of a chest like this without removing many of the tools at the jobsite, and packing them back in at the end of the day.

In your 1/4/13 post you stated that had two (2) smoothing planes in your tool box… down from five (5)!

Very curious…

of the 2 you had in your 1/4/13 post –

which one was deleted and which one made the final cut?

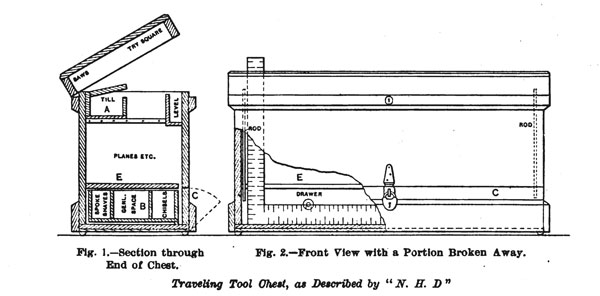

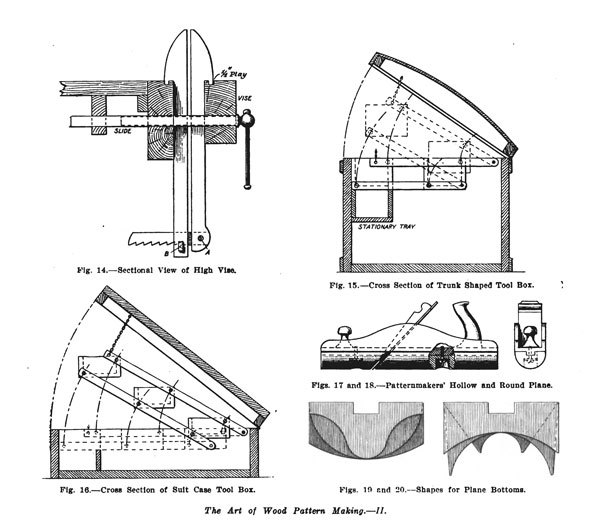

The parallelogram trays in “The Art of Pattern Making -11” look interesting, have you seen this in the wild? Any obvious cons?