We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

When you have to work inside a carcase, there are a wide variety of specialty tools on the market – such as right-angle drills and drawer-lock chisels – to make your life easier.

I try to keep a small tool kit. Not because I’m a tightwad. I’m not. But I travel a lot and I prefer to have fewer tools to take care of and keep track of. Buying fewer tools also gives me more money for wood and beer.

Here are a few of my favorite tricks for working in tight spaces with regular tools.

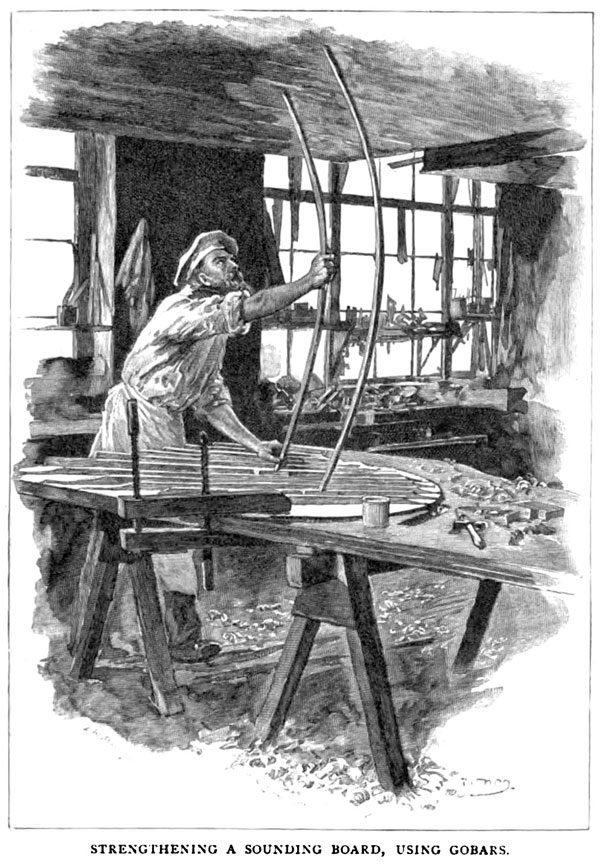

1. The ‘goberge.’ One of the toughest things about working inside a carcase is when you have to glue and clamp something in the middle of the case. Sure, you can buy some crazy expensive deep-throat clamps. Or hope that a nail or screw will do the trick. I prefer the “goberge” – usually called a “go bar” in this country.

It’s a stick that is slightly longer than the space in which you need to apply pressure. The corners are chamfered a tad with a chisel. This allows the goberge to get wedged inside the case. Then you tap it with a mallet until you have the pressure you need.

This is a very old trick – the earliest place I’ve seen it was in a 17th-century French text.

Many woodworkers and piano makers use these goberges against the ceiling for applying pressure to the middle of panels on the bench. (Note this will not work with a modern drop ceiling or drywall ceiling. You have been warned.)

2. Butt chisels. I’ve never owned a butt chisel. Instead, I have socket chisels and remove the handle when I need to chop inside a tight space. Rap the handle hard against the bench a few times and the socket will release its hold on the handle. To reset the handle, put it in its socket, hold the socket and hit the butt end of the handle against the bench.

If your handle comes loose too easily, spray it with a squirt of hairspray – yes, hairspray. Let it dry for 10 seconds and then drive the handle on. The hairspray will allow you to remove and reset the handle many times before having to respray the handle. In other words, you don’t have to have a bottle of hairspray in your tool chest.

3. Hand drills. I use a hand drill for almost all of my small-diameter holes. When installing locks inside small cases or doors, it can be hard to get any drill in there. So I unscrew the handle and get to work. Not all of the handles unscrew, but many do. If you are in the market for a hand drill, look for one with a removable handle. (No, I don’t have a list of models and makes to guide you. You are on your own.)

4. Japanese nailset. If you don’t have a nailset, consider getting this inexpensive one. It’s available everywhere. The two heads allow you to get into tight spaces. You can easily grind or file the other tip to suit your work.

5. A file handle. An old book called “Jobbing Work for the Carpenter” by E.H. Crussell convinced me to pick up one of these for a few bucks at a tool meet. I love it. When it comes to improvising in the shop, this is your best friend. Don’t have a scratch awl? Clamp a nail in the handle. Need a birdcage awl? Clamp a cut nail in the handle. The chuck of the tool will hold a surprising range of items – knife tangs, burnishers, jigsaw blades, countersinks.

— Christopher Schwarz

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Drywall hangers will often use a deadman (usually made from 2×4’s) to support panels when there’s not enough human help around. Sure, there’s another plank nailed to the top of the go bar to spread the pressure out (and not puncture the sheet), but otherwise the wedging principle is the same. And it really helps with the 12 and 16 footers when a hoist isn’t available.

I’ll add a ‘me too’ to this thread. I bought a set of small brass mallets from Lee Valley to try my hand at carving. I use them more in place of my wood mallet in tight spaces than carving. A nice bit of mass in a short arc works wonders in a tight space.

http://www.leevalley.com/US/wood/page.aspx?p=70377&cat=1,41504,43688

More than once I’ve drilled holes or driven screws in tight places by chucking hex-shank bits in a 1/4″ ratchet. A piece of wood with an appropriate hole quickly makes standard irwin auger bits into t-auger bits to allow you to drill a larger hole in a smaller space than your brace fits. Shorter auger bits are even better for this if you can find them. A not-great shape bit, where someone already cut off the square part of the shank can be cut down further and turn with pliers if you have to. Auger bits are awesome for this because the lead screw keeps the bit engaged, (and in place) so even if you can only turn a little bit at a time, you can get there. ( I usually try and plan better, but this was for installing a goldenrod in a tool cabinet after the fact.)

Luthiers use gobars a lot to hold down the backs and tops of their instruments as they glue the braces on. There’s a lot of electronic ink spent on building gobar benches for those attempting to ply their hand at hand building a guitar.

I tried. It burned well in the stove…