We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

We all know that Joseph Moxon didn’t invent the Moxon vise. But perhaps the Italians did?

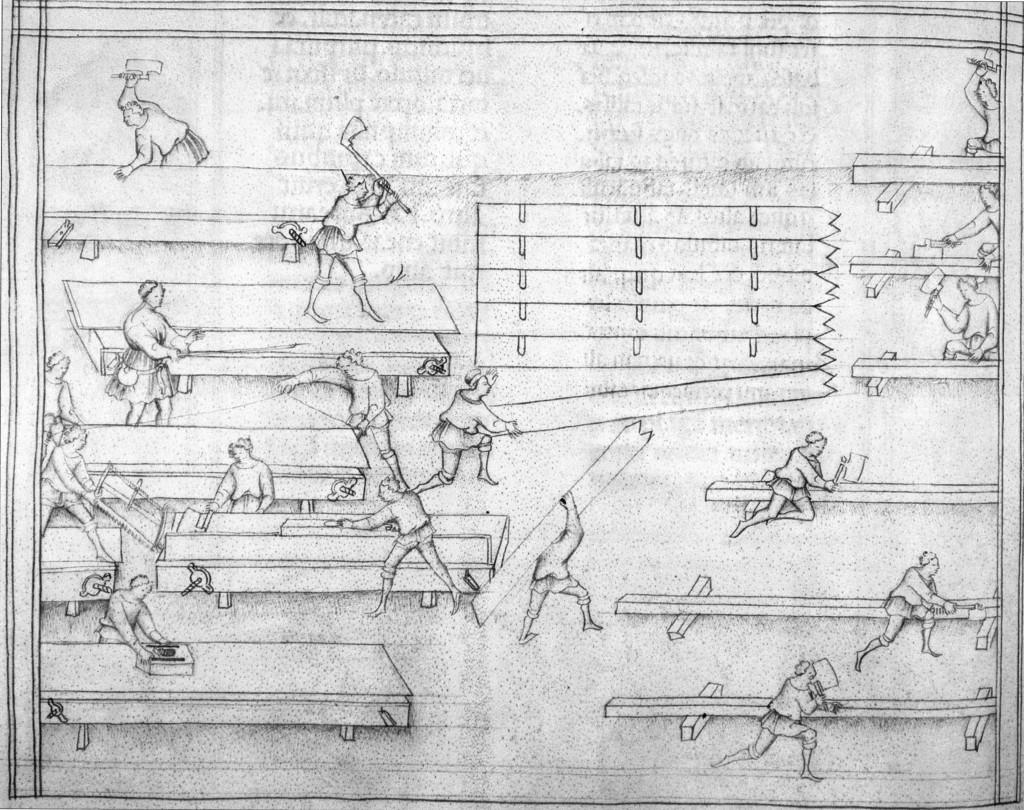

I spent a fatigue-fueled weekend researching some red herrings and stumbled on this circa 1300 hand-drawn illustration of the construction of Noah’s Ark. I found the plate in “Les Rabots,” a fantastic modern book on handplanes in French. (Someone should really translate it; please don’t ask me to do it.)

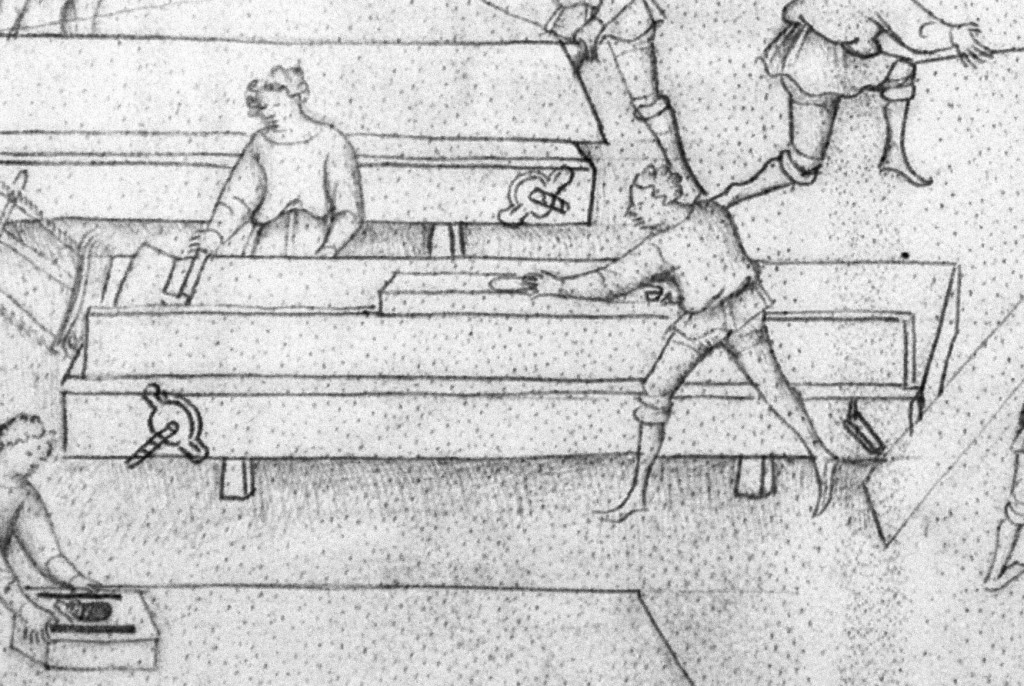

The drawing from Northern Italy shows six Roman-style workbenches outfitted with massive edge-planing vises that span the entire length of the benches. On one end of the vise’s jaw is a bench screw. At the other end is a parallel guide that is pierced by holes for wooden pegs. The parallel guide is the pivot point for the vise jaw and allows the worker to operate the vise alone.

(Interestingly, two of the four benches have the screw on the left side of the bench. The other four have the screw on the right side. I’ll let you draw your own conclusions.)

Judging from the scale in the drawing these vises and benches are 8’ and 10’ long. So yeah, they could handle a 24”-wide case side for dovetailing.

There’s a lot going on in this drawing. So I’ve included a large version of it for you to explore in this link:

— Christopher Schwarz

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Chris

Is it my old eyes or, as usual , I’m missing the point. It appears to me that these are bench long permanent face vises. They sure would be nifty for planing and otherwise working on long stock and also for dovetailing. I suggest the term vise, as used in “Moxon Vise”, can be misleading. Moxon himself called the device the “double bench screw”. The essence of the double bench screw is its portability. It is secured by holdfasts any where on or half off the bench depending upon the location of holdfast holes. It is also easily removed. No holes, no holdfasts? You can still use the double bench screw anywhere on the top of the bench as Peter Follansbee does. He uses it as a free standing clamp or jammed against a metal bench hook for chiseling or planing.Because of the double bench screw’s portability It is easy to think up other uses. Im sure Peter has. Oops, I remember we used it as a free standing vertical “clamp” , anywhere on the bench, to hold vertical stock to split off 17 Century tenon waste. Because of its portability and thanks to today’s dovetailer it enjoys an exciting new life.

Jennie

What a great drawing. I love the details. Especially what looks like one worker using a chalk line to mark a board.

It also looks like the bench top only comes up to the height of the worker’s knees… This would work well for wide (I mean REALLY wide) boards, but what about thinner stock? I guess if you’re building the Ark all of your boards are wide, old growth timbers, eh?

Date of the drawing?

As the board is held at the top of the vise, the face plate will tilt and grab only the bottom of the board that may be tilted to, a problem when jointing. No idea how they solved that problem.

Now you show me. I just finished cutting the vise jaws the day after PBS aired the show with you and Roy making a vise. Mine is made of cherry left over from my last project. I am using Jorgensen press clamps for the screws. I am putting an ebony wear surface on the top of the front jaw so I can use it as a guide to level the bottom of the tail and pin cuts and not wear the vise jaw top. If the ebony gets too rough I can saw it off and replace it with a new top. The holes for the screw in the front jaw will have brass liners in them to keeo them from getting too large over time. Finish, dewaxed garnet shellac rubbed out with BriWax and 4/0 steel wool.

Guessing, of course, but when I look at the full scene, I see that 3 of the 4 benches with the screw on the right have the view of the left end of the bench blocked .

The 4th bench, clearly, was just a matter of incorrect copy/paste in photo-shoppe.

That guy planing the edge must be close to 9’6″ and wielding a 6″x6″, six foot long jointer! 😛

Thanks for the freebie.It is tragic but I do believe that is a woman as my great great Aunt Nina I was told in joking fashion was able to throw her dual front appendage over her shoulder because of the lack of proper support back in the day. The applicator she employs is definitely called the ex-mother in law tongue. It will go without stopping all day,I know it wore me out.