We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Boiled linseed oil darkens. Boiled linseed oil (shown here on oak) and, to a lesser extent, varnish darken considerably as they age. On the left is freshly applied boiled linseed oil. On the right is boiled linseed oil that has aged about 10 years.

Different finishes look different on different species.

There are many reasons to choose one finish over another. Usually the most important is for protection and durability – how well a finish protects the wood from moisture and how resistant the finish is to being damaged by coarse objects, heat and solvents.

Other significant factors include drying time (you don’t want a fast-drying finish if you’re brushing) and odor (some finishes have a less irritating aroma than others).

There’s also color. Finishes differ in color, or the amount of color, they add to wood. For example, clear paste wax adds the least amount of color and the least amount of darkening to wood. Wax adds a little shine, but otherwise leaves the wood looking very close to natural.

Water-based finishes don’t add color either, but they do darken the wood noticeably. The lack of color can be an advantage on “white” woods such as maple or ash or a disadvantage on darker woods, making them look “washed out.”

Nitrocellulose lacquer and blonde or clear shellac add a slight yellow/orange tint to wood. But not nearly as much as does orange or amber shellac. (Shellac in flake form is usually labeled blonde and orange. In prepackaged liquid form the equivalent to blonde is “clear” or “SealCoat.” The equivalent to orange is “amber.”)

Oil-based varnish, including polyurethane varnish, and boiled linseed oil add a darker yellow/orange tint than lacquer or blonde/clear shellac. More significantly, varnish and oil continue to darken as they age – boiled linseed oil considerably more than varnish.

Mixtures of varnish and oil, often sold as “Danish Oil,” fall in between varnish and oil in their tendency to darken depending on the ratio of each that is included.

The Seven Finishes

Seven finishes on maple. Top row from left: unfinished, clear paste wax, water-based finish, nitrocellulose lacquer. Bottom row from left: clear/blonde shellac, amber/orange shellac, polyurethane varnish, boiled linseed oil.

You’ll find on these pages pictures of the seven finishes (not including oil/varnish blends) on four different woods – maple, oak, cherry and walnut – to illustrate the differences in the amount of color each adds. Be sure to look closely at the woods in each of the pictures. The finishes have somewhat different effects depending on the wood.

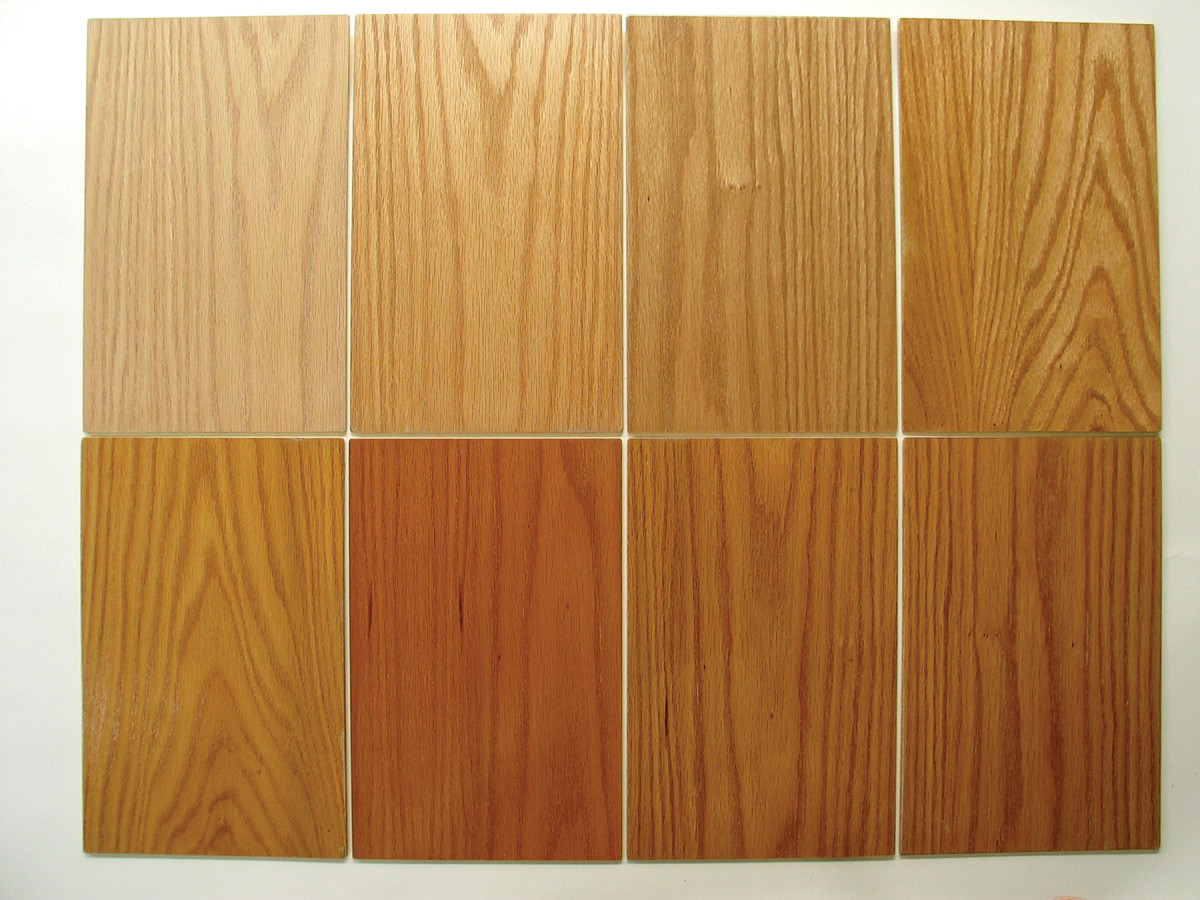

Seven finishes on oak. Top row from left: unfinished, clear paste wax, water-based finish, nitrocellulose lacquer. Bottom row from left: clear/blonde shellac, amber/orange shellac, polyurethane varnish, boiled linseed oil.

I used the most commonly available finishes within each finish category for illustration. But there are exceptions within each of the categories. For example, though most brands of paste wax offer only a clear, some add pigment to produce colored paste waxes.

Seven finishes on cherry. Top row from left: unfinished, clear paste wax, water-based finish, nitrocellulose lacquer. Bottom row from left: clear/blonde shellac, amber/orange shellac, polyurethane varnish, boiled linseed oil.

Though rare, some manufacturers of water-based finishes add a little dye colorant to make the finish better resemble the look of nitrocellulose lacquer. Information on the can or in the promotional literature will inform you of this.

Within the lacquer category, CAB-acrylic and water-white lacquers add considerably less color than does nitrocellulose lacquer. In fact, a good quality CAB-acrylic lacquer adds no color, similar to water-based finish. But it does bring out the richness of darker woods better than water-based finish.

Seven finishes on walnut. Top row from left: unfinished, clear paste wax, water-based finish, nitrocellulose lacquer. Bottom row from left: clear/blonde shellac, amber/orange shellac, polyurethane varnish, boiled linseed oil.

In addition to clear/blonde and amber/orange shellac, some specialty suppliers offer a number of additional colors, including garnet, button, extra dark and various shades of lemon.

Depending on the oils and resins used in manufacture, some varnishes darken wood more than others. For example, Waterlox, which is a popular wiping (thinned) varnish used by woodworkers, is made with phenolic resin and tung oil, both of which are darker than the more common alkyd and polyurethane resins and soybean oil used to make most varnishes.

Though rarely used by itself as a finish, 100 percent tung oil darkens a little less over time than boiled linseed oil.

In choosing a finish for your project, you need to take into account a number of characteristics of the various finishes. One is the color the finish adds, or doesn’t add, to the wood.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.