We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Try dividing large objects into smaller parts, or get someone else to apply or wipe off.

With this information you may be able to avoid the problems entirely.

Problem #1

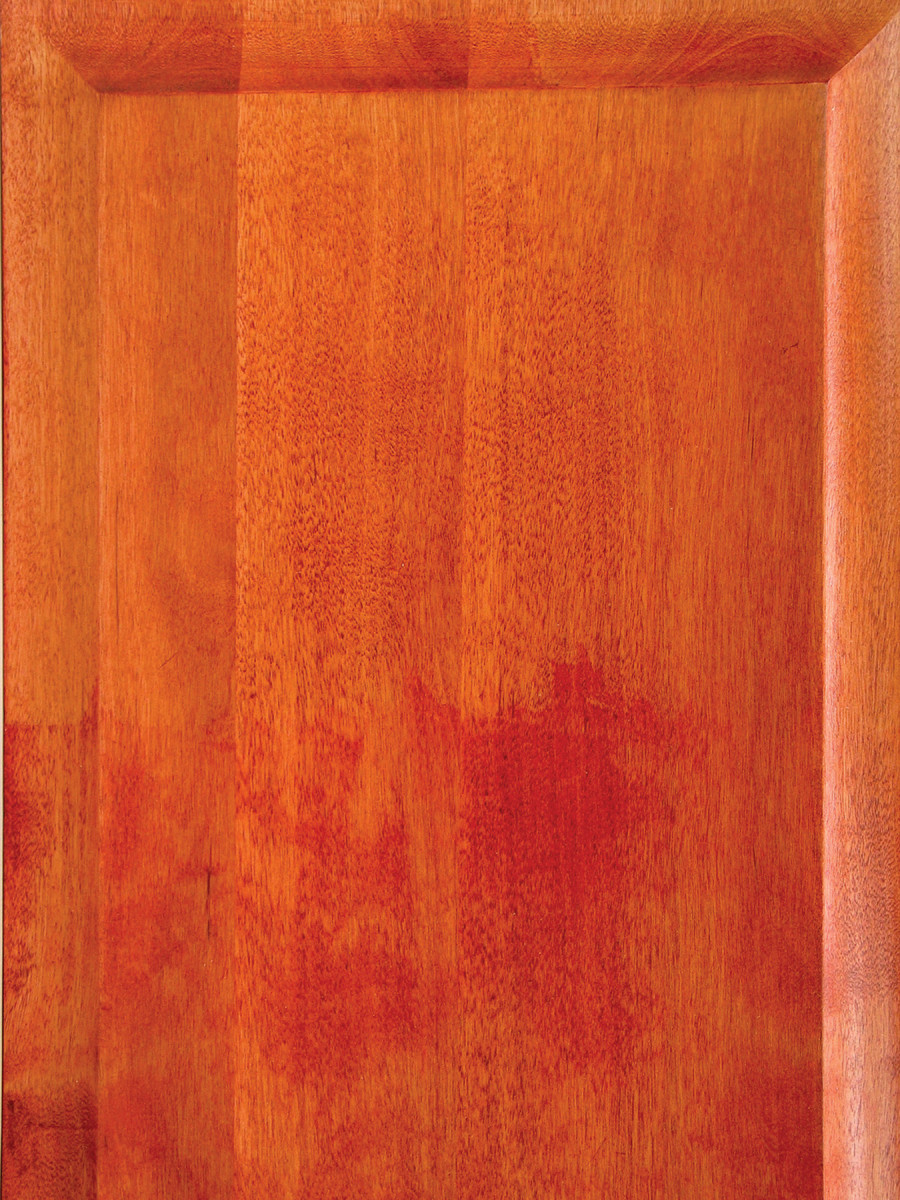

Different boards on glued-up panels take stain differently, some boards coming out lighter than others.

Fix Apply more stain to the lighter boards either directly on the wood or by adding some of the stain color to the finish and shading them darker. It’s seldom possible to get an exact match, but you can reduce the contrast significantly. Another way to even the coloring is to bleach the wood using a two-part bleach (sodium hydroxide and hydrogen peroxide), then stain the wood to the color you want after sanding to remove the fuzz.

Problem #2

The stain dries before you can get all the excess wiped off.

Fix This problem is fairly common with water-based and lacquer-based stains because both dry rapidly. Apply more of the same stain, the thinner for the stain, or if necessary, a paint stripper, and remove the excess stain. If the color is then not even, or it’s too light, you’ll need to apply more stain. Switch to a slower drying stain, work on smaller sections at a time, or apply and wipe off the stain faster by using a cloth or spray gun to apply the stain and a large dry cotton cloth to remove the excess stain. You can also get someone else to perform one of the steps while you do the other. Stains that thin or clean up with mineral spirits (paint thinner) dry the slowest, but you have to wait longer before applying a finish.

Problem #3

1. If you sand through an edge, an easy way to put the color back is with a touch-up marker. Then apply some finish to prevent the marker color from being wiped off.

While sanding the sealer coat, you sand through the stain on some edges.

Fix Replace the color by applying some of the same stain to the area and wiping off all the excess, or by using a touch-up marker.

Problem #4

The end grain on raised-panel cabinet doors gets too dark when you wipe on and wipe off a stain.

Fix Sand the end grain so there’s absolutely no remaining roughness, or spray the stain in light enough coats so you don’t need to wipe off any excess. The darkening is caused by more stain lodging in the rough areas in the end grain than in the smooth-sanded areas in the long grain of the rest of the door. Spraying stain without wiping deposits an equal amount of color everywhere, so the roughness doesn’t impact the darkness of

the color.

Problem #5

2. A common flaw when staining is machine marks such as those shown here telegraphing through and, in fact, being highlighted. You need to sand these out before applying the stain.

The stain highlights gouges and machine marks (“washboarding”) left by a jointer or planer. Also highlighted are the sanding scratches left by coarse-grit sandpaper and the squiggles left by random-orbit sanders.

3. To avoid blotching on softwoods and most tight-grained hardwoods, apply a washcoat before staining. Oil- and varnish-based washcoats are commonly sold as “wood conditioner.” These dry slowly, so you should give them six or eight hours before applying the stain.

Fix Re-sand the wood to below the depth of the problems up to #150- or #180-grit sandpaper. Before beginning, wipe off as much of the stain as possible using naphtha, lacquer thinner or acetone so the stain doesn’t clog the sandpaper. You don’t have to remove all the stain color before re-staining, just get the remaining color fairly even.

Problem #6

The stain blotches the wood even when you remove all the excess.

Fix The blotching is caused by flaws in the wood that absorb more stain, so the solution is to keep all the stain very near the surface of the wood. You’ll have to remove any blotching that has occurred by sanding. Then switch to a gel stain (which doesn’t flow so it doesn’t penetrate deeply), partially seal the wood with a washcoat/wood conditioner (to keep the stain from penetrating deeply), or spray the stain and don’t wipe off the excess. This will leave an equal amount of stain everywhere.

Problem #7

Spray stain doesn’t color inside corners well.

Fix The turbulence created by the air pressure prevents the stain from reaching these recessed corners. So reduce the air pressure to the minimum possible, while still getting good results, or brush the stain into these areas.

Problem #8

Places where sweat has dripped on the wood during sanding come out darker when you apply the stain.

Fix The sweat (or any water for that matter) raises grain and roughens the wood, so more stain lodges. Follow the directions in problem #5 for sanding the problem and re-staining.

Problem #9

The stain you’re using doesn’t get the wood dark enough.

Fix Commercial stains vary in the ratio of pigment or dye they contain relative to vehicle (binder and solvent). The higher the ratio the darker the stain colors the wood. So an easy solution might be to change brands or to add some pigment or dye to the stain you’re using.

There are two other possibilities. One is to sand to a coarser grit: #150 instead of #180, for example, or #120 instead of #150. Just don’t get so coarse that the stain highlights the scratches. You’ll have the greatest success if all the sanding-grit scratches from the last sanding go with the grain.

The other is to leave some stain on the wood during the wiping stage. This is called a “dirty wipe.” To achieve success you must wipe every part the same, so it’ll help to have a sample panel to match. Apply a coat of finish to this panel to bring out the full color.

Problem #10

The color of the stained wood is just a little off.

Fix Add a little of the opposite color in the color spectrum to the finish and tone the wood. For example, if the wood is too warm (reddish), add green. If the wood is too cool (greenish), add red. You can also add black to reduce brightness. Keep in mind that lighting plays a part in how colors appear. Fluorescent lighting causes colors to appear cooler. Incandescent lighting causes colors to appear warmer.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

With the Jets (4-12) sitting home for the postseason for the fourth consecutive year, Johnson chose to start fresh with [url=http://www.fanscowboysteamstore.com/]Cheap Dallas Cowboys Throwback Jerseys[/url] a new coach and GM 锟?and said [url=http://www.cheapfanatics.us.com/Arizona-Cardinals-Brice-Butler-Gear/]Brice Butler Jersey[/url] the team already contacted the top candidates on his short list. He wouldn’t immediately reveal who they are, but the Jets are scheduled to meet with Seahawks defensive coordinator Dan Quinn 锟?a former New York [url=http://www.nfljerseyswholesalesale.us.com/]Wholesale Nike NFL Jerseys[/url] assistant 锟?in Seattle on Saturday for the coaching position.

The improved defense [url=http://www.cheapnbajerseysstore.us.com/]Cheap Jerseys Free Shipping[/url] has been led by Mack, who has quickly established [url=http://www.nbawholesalejerseys.us.com/]China Jerseys Wholesale[/url] himself as one of the top edge rushers in the league in his second year with his ability to stop the run and pressure [url=http://www.stitchedjerseys.us.com/]Cheap Jerseys From China[/url] the quarterback. Newcomer Aldon [url=http://www.wholesalejerseysnflonline.us.com/]Wholesale Jerseys[/url] Smith has added help on the other side and free agent acquisition Dan Williams has solidified the run defense.

Walters had two receptions for 17 yards in the season opener against Carolina. He was released six [url=http://www.cheapnhljerseys.ru/]Cheap Hockey Jerseys[/url] days later.

“The bottom line is: the NFL wants a team in LA,” Burton said, “for the ratings and for what it means to the broadcast contracts and packages. But picking the right team to go to LA is [url=http://www.cheapnhljerseys.ru/]Cheap Hockey Jerseys[/url] about a lot of potential lawsuits.”

EXPECTATIONS: Ravens intend to make playoffs again, and [url=http://www.jerseysauthentic.us.com/]Cheap Jerseys[/url] this time they’d [url=http://www.wholesalejerseyschinanfl.us.com/]White NFL Jerseys Cheap[/url] like to do so as AFC North champions. For this to happen, Baltimore must adjust quickly to Trestman’s offensive scheme and get most out of Flacco and offensive line that is unchanged from a year ago. Ravens also expect rookies, most notably Perriman, TE Maxx Williams and DT Carl Davis, to contribute immediately.

Browns Pro Bowl tackle Joe Thomas said Moeller addressed his linemen and told them a little about his situation. Thomas is confident his group won’t be adversely affected by the suspension.

I have moved away from pigmented stains to Transtint and Behlen dyes, for several reasons. First, I can apply diluted aliquots and sneak up on the color I want much easier, without having to wait for other stains to dry. Second, I work a lot with maple, and have learned to stain it (assuming a reasonable amount of grain showing) to look like other woods. Third, I found that I could use it in an airbrush on whitewood areas to color them to match adjacent wood, saving a lot of wood that would otherwise be rejected; in many cases, it is impossible to discern the difference. Fourth, the transparancy compared to pigmented stains is remarkable. If you have not tried this approach, give it a try. One friend commented that Transtint is about $10 per ounce; that 2 oz. bottle being almost $20 – my response was that I could make can make 1/2 gallon with that 2 oz. bottle. I love blending colors.