We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

In the previous issue I wrote about teak oils and how none have anything to do with teak wood. Reading the article, you may have asked yourself why companies would put out products that aren’t what they say they are and don’t do what they say they do.

I used to think the people at these companies knew better and did this to fool us. But after more than 25 years of dealing with them, I’ve come to believe that many who target the DIY market just don’t understand their products. The companies aren’t actually finish companies; they’re marketing companies. They just sell stuff, using whatever labeling or claims they think will work.

How can they do this and get away with it, you ask? In my opinion it’s because finishes are chemistry – in contrast to woodworking, for example, which is physics. You can see that a band saw isn’t a table saw, even though it, too, has a table. But you can’t see the difference between varnish and lacquer, either in the can or on the wood – and they are very different finishes.

Because many marketing people have little understanding (even though their products are usually very good), we, the users, struggle. How else can you explain the following examples?

Watco Danish Oil

Watco Danish Oil. The application method Watco suggests on its label is a two-step single coat, both steps applied within 45 minutes. This results in a slightly duller and clearly rougher feeling surface (left half of surface) than the better application method (right half of panel) suggested by experienced woodworkers for nearly 40 years.

Watco Danish Oil was introduced to the woodworking community in the second issue of Fine Woodworking in 1976. The application directions in the article were good, and they have been repeated by writers and teachers countless times since: Apply a wet coat; let it soak in; wipe off; let dry overnight; sand smooth; apply a second coat, and maybe a third after another day.

But the directions on the Watco can were (and still are): Apply a wet coat; wait 30 minutes; reapply; wipe dry after 15 minutes. This doesn’t produce good results because it’s really just one coat. The first hasn’t dried before the second is applied. The full sheen and smoothness of any finish isn’t produced until a second coat is applied over a dry and sanded first coat.

But in nearly 40 years, as Watco was bought and sold by many companies, (It’s now owned by Rust-Oleum), these directions never changed.

Minwax Wood Finish & Wood Conditioner

Minwax Wood Conditioner. The company says to apply the stain within two hours of applying the conditioner. Shown on this panel, left to right, is the stain applied directly to the wood; immediately after applying the conditioner; after 10 minutes; after two hours, and finally after overnight drying. Notice that the blotching actually gets worse (because of the evaporation of the thinner) the longer the elapsed time until the thinned-varnish conditioner has fully dried.

Minwax has also been bought and sold many times, most recently bought by Sherwin-Williams. But the name, “Wood Finish,” on their yellow cans of stain has never been changed to reflect what the product really is – a stain. Though experienced woodworkers know this, the mislabeling causes confusion for beginners.

Minwax also makes “Wood Conditioner” and provides instructions on the can for avoiding blotching. Apply a wet coat; wipe dry after five to 15 minutes; apply the stain within two hours.

These directions don’t work well. The wood conditioner is varnish thinned with about two parts mineral spirits. It requires six hours to overnight to dry and become effective at reducing blotching.

3M Safest Stripper

3M Safest Stripper. Because of the high percentage of water in this paint and varnish remover, steel wool used for scrubbing off the sludge rusts and causes black marks on the wood. This caught the manufacturer by surprise. To fix the problem, 3M put this warning sticker on the cap.

3M Safest Stripper was introduced in the early 1990s as a substitute for strippers based on methylene chloride, which was a suspected carcinogen. The stripper is almost unique in that it contains 65 percent water.

Apparently no one at 3M understood the relationship between water, wood and paint stripping.

Safest Stripper works very slowly, so it has to be left in contact for a long time. This can cause veneer to lift, especially on old furniture (pre-1950) glued with animal hide glue, and it causes steel wool to rust and leave black marks on the wood. The formulators had apparently been using 3M’s own Scotch-Brite pads, and no one had enough experience with stripping to realize that most people use steel wool.

Olympic Stain

Olympic Stain had been the best-known deck stain for decades. When PPG bought it in the mid-1990s, they did a survey and found that Olympic was the second best-known interior stain behind Minwax, even though Olympic didn’t make interior stains.

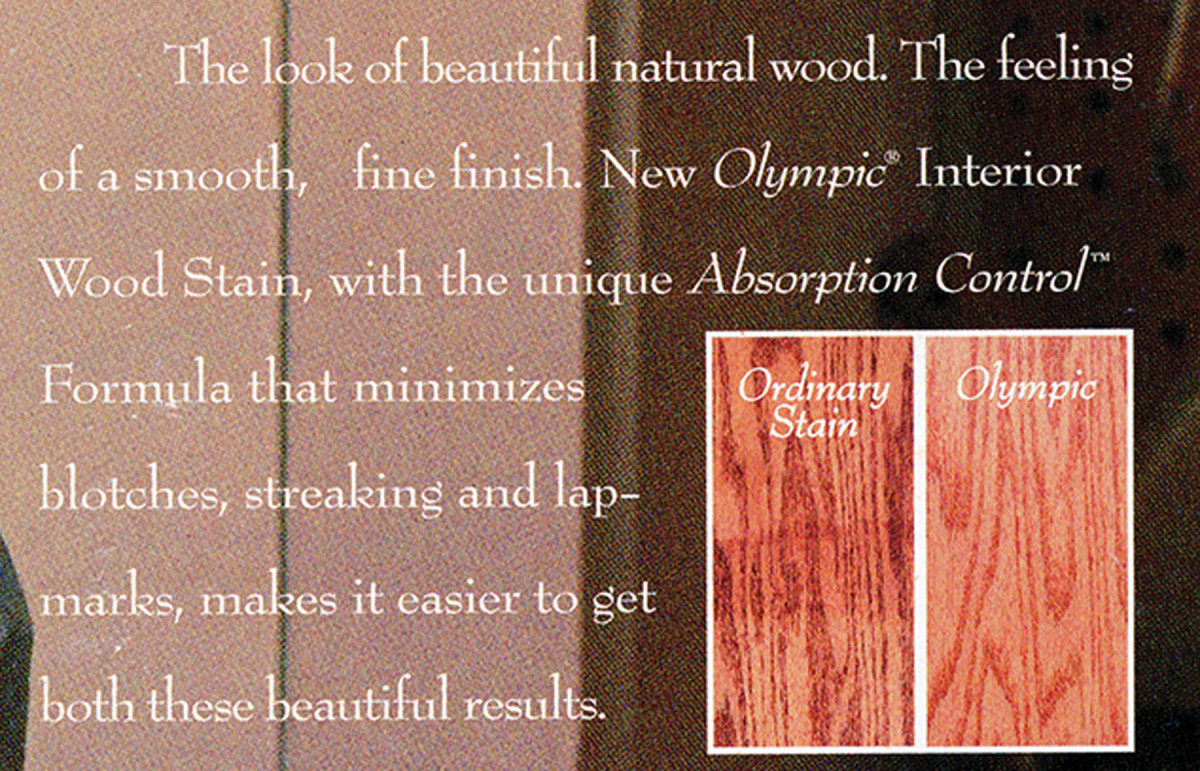

Olympic Stain. This is a part of the ad Olympic Stain ran in woodworking magazines to introduce their interior stain. The oak on the left is blotched, but oak doesn’t blotch. The only ways I can think of to get oak to look like this are to do a poor job of sanding or generate the image on a computer.

Being good marketers, they quickly introduced a line of interior products modeled after Minwax, and they advertised for months in woodworking magazines with one- and two-page advertising spreads.

Highlighted in the ads were two pictures of oak, one blotched with an “ordinary” stain, the other an even color with their “absorption-control” stain. The problem is that oak doesn’t blotch! Apparently, no one at Olympic knew this. Pine and cherry blotch, and Olympic stain blotches them just as all liquid stains do.

Carver Tripp Safe & Simple

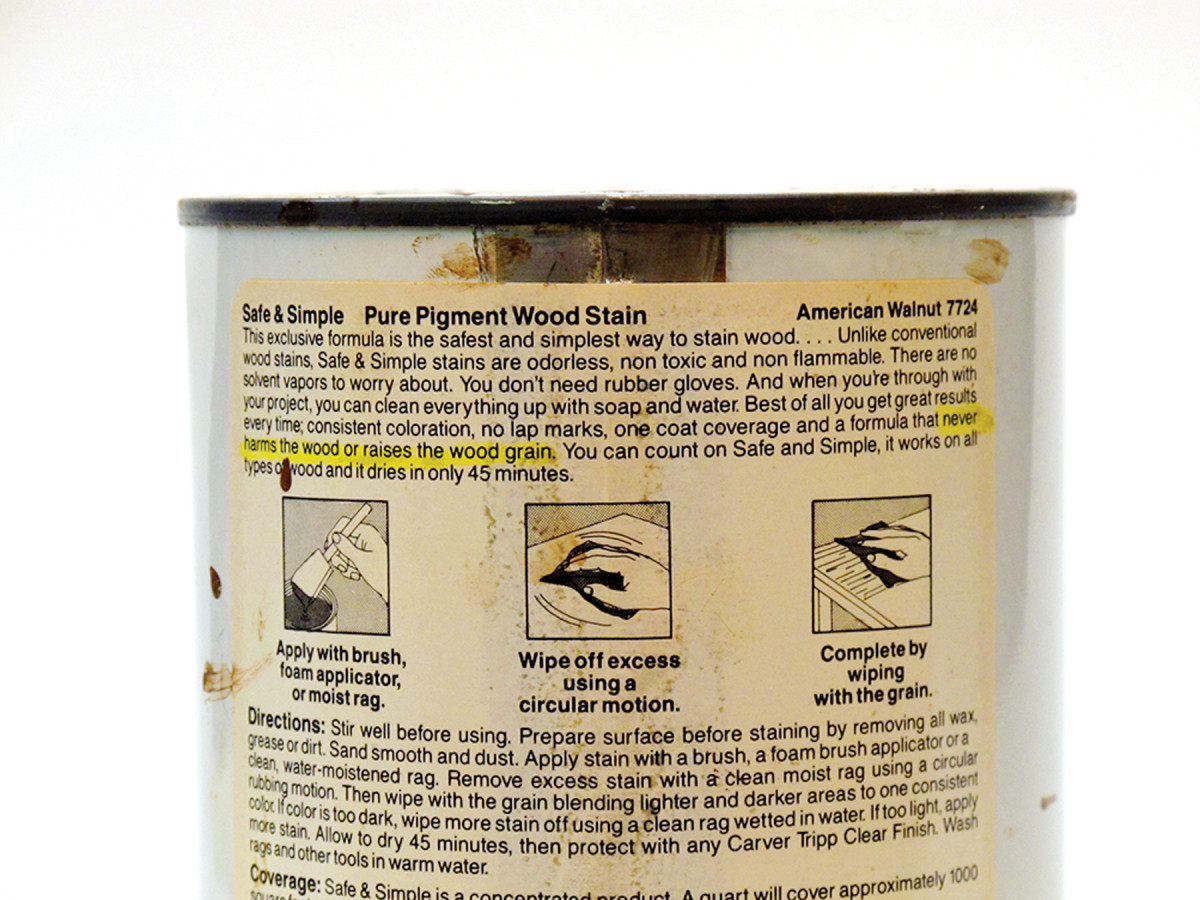

Carver Tripp water-based stain. To deal with the problem of water-based stains raising the grain of the wood, the marketers at Carver Tripp simply said theirs didn’t. Did no one try the stain or realize how obviously false this claim is and that making it might damage the reputation of the company?

Carver Tripp was once a prominent finish company sponsoring Norm Abram. The company made a water-based wood stain called Safe & Simple. One big issue with water-based stains was, and still is, that they raise the grain of the wood. So Carver Tripp dealt with this problem by simply claiming on the label that their stain “never harms the wood or raises the wood grain.”

Did no one at Carver Tripp know enough about water and wood to realize that making such an obviously false claim might not be a wise thing to do? Carver Tripp no longer exists.

General Finishes Seal-a-Cell

When I was writing “Understanding Wood Finishing” in 1993, I called General Finishes to ask about Seal-a-Cell, which was, and still is, represented as an oil sealer that “penetrates deep within the wood.” But a puddle dries hard and smooth, so it had to be varnish. (Varnish is made with oil, but it’s no longer oil and the oil part can’t act separately.)

Seal-a-Cell wiping varnish. The way to tell if a finish that thins and cleans up with mineral spirits is oil or varnish is to put a puddle on a non-porous surface. If the puddle dries soft and wrinkled, it’s oil or oil/varnish blend. If the puddle dries hard and smooth, it’s varnish. This is clearly varnish despite the claims of the manufacturer.

To prove that the finish was oil, the owner told me the main ingredient: alkyd-modified linseed oil. This, of course, is a more technical name for varnish! He didn’t know.

I think it’s manufacturer ignorance that is most responsible for making finishing so difficult to understand. This explains why the help you get when you call these companies is so poor.

The products are good; the instructions and claims are not.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.