We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

My wife and I were walking through a Home Depot store about 20 years ago, when I noticed a small Makita tablesaw and mentioned that it would be fun to have a tool like that just to fool around with. That very saw appeared under the tree at Christmas, and it ignited my passion for woodworking. I bought more tools, then books and videos and even more tools.

My wife and I were walking through a Home Depot store about 20 years ago, when I noticed a small Makita tablesaw and mentioned that it would be fun to have a tool like that just to fool around with. That very saw appeared under the tree at Christmas, and it ignited my passion for woodworking. I bought more tools, then books and videos and even more tools.

Eventually, tools were piled up in the garage. Every time I wanted to make something, I had to back the cars out and pull the tools into the space. As this struggle continued, I dreamed of having a shop big enough to have a dedicated space for all my woodworking tools. So when the property next door came up for sale a few years back, we bought it and tore down the old house. Then I designed a shop from scratch, using my skills as a real-estate developer. From the outside, it has the look of a nice home with a landscaped yard.

Eventually, tools were piled up in the garage. Every time I wanted to make something, I had to back the cars out and pull the tools into the space. As this struggle continued, I dreamed of having a shop big enough to have a dedicated space for all my woodworking tools. So when the property next door came up for sale a few years back, we bought it and tore down the old house. Then I designed a shop from scratch, using my skills as a real-estate developer. From the outside, it has the look of a nice home with a landscaped yard.

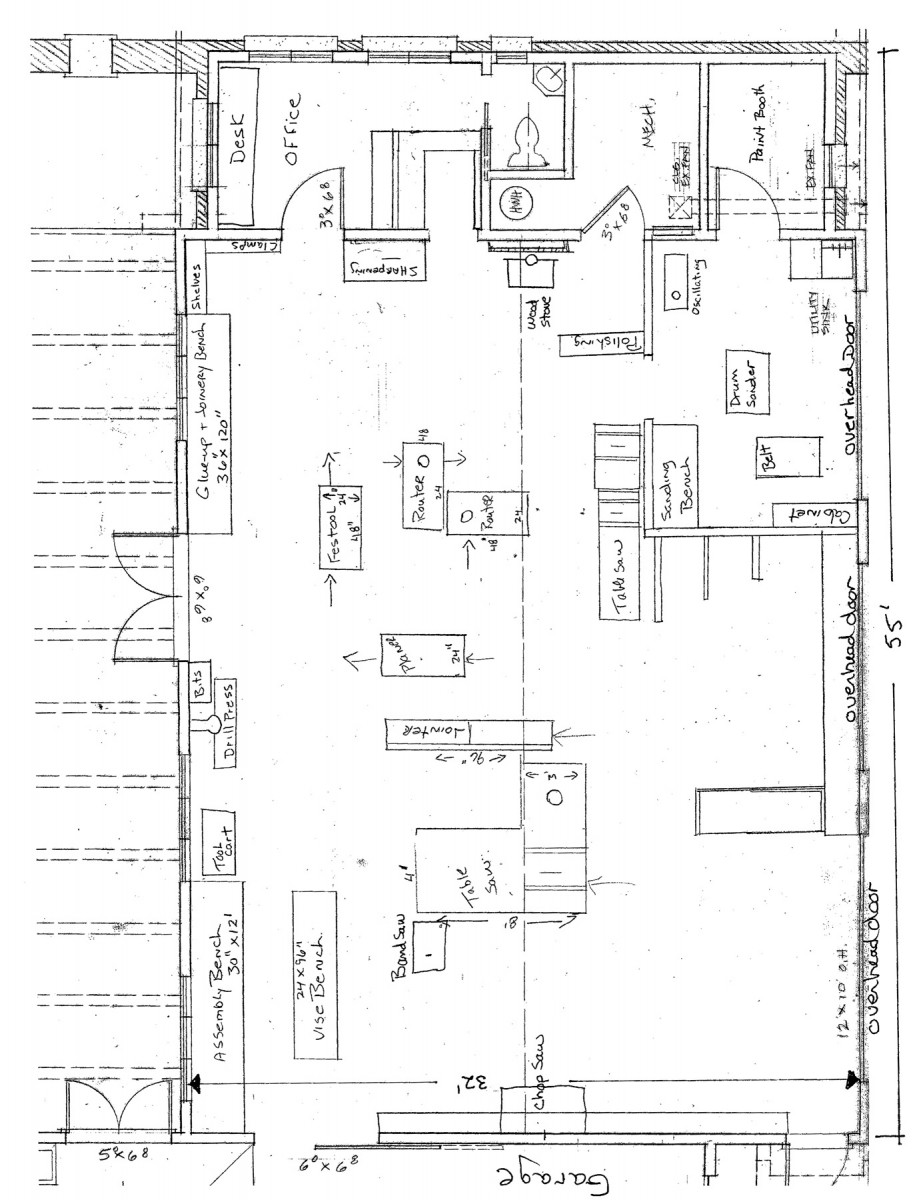

The structure is essentially a four-car garage with an additional wing to house the mechanical rooms and office. I’d had it with tripping over hoses and cords in my old garage space, so one goal in laying out the new shop was to locate power, compressed air and dust control near each tool. I also positioned the tools to maximize the work flow from one operation to the next, with work stations adjacent to the tools associated with each task. The shop revolves around two centrally located columns that are actually 24″ x 24″ chases for power, air and dust collection.

The structure is essentially a four-car garage with an additional wing to house the mechanical rooms and office. I’d had it with tripping over hoses and cords in my old garage space, so one goal in laying out the new shop was to locate power, compressed air and dust control near each tool. I also positioned the tools to maximize the work flow from one operation to the next, with work stations adjacent to the tools associated with each task. The shop revolves around two centrally located columns that are actually 24″ x 24″ chases for power, air and dust collection.

A large maple workbench set up for clamping and assembly occupies one wall. It has full-extension drawers to house all the clamps. (There are never enough!). Another similarly sized bench has similar drawers for hand tools. Yet another bench is reserved for tool sharpening.

A large maple workbench set up for clamping and assembly occupies one wall. It has full-extension drawers to house all the clamps. (There are never enough!). Another similarly sized bench has similar drawers for hand tools. Yet another bench is reserved for tool sharpening.

Dedicated rooms flank the main shop area: an office, a room to house noisy machines such as the compressor and dust collector, a tool room lined with shelves, a finishing room with a spray booth and ventilation fan, and last but not least, a sanding area with a downdraft table.

Dedicated rooms flank the main shop area: an office, a room to house noisy machines such as the compressor and dust collector, a tool room lined with shelves, a finishing room with a spray booth and ventilation fan, and last but not least, a sanding area with a downdraft table.

Three large overhead doors provide virtually unlimited access and a side door opens to a nice porch, the perfect spot to rest after a hard day’s work.

Three large overhead doors provide virtually unlimited access and a side door opens to a nice porch, the perfect spot to rest after a hard day’s work.

I build furniture for use in our house and small items to give as gifts. I still consider myself a novice woodworker, but my skills are continually improving as I acquire new tools and learn new techniques. As a result, my projects usually end up better than originally planned. Kristo Zorkin, Medina, WA

I build furniture for use in our house and small items to give as gifts. I still consider myself a novice woodworker, but my skills are continually improving as I acquire new tools and learn new techniques. As a result, my projects usually end up better than originally planned. Kristo Zorkin, Medina, WA

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Awesome shop!

I am building a 30×40 shop right now, and have a blank slate to work with.

I am putting the air compressor and dust collector in the bathroom, and I also plan to build a finishing room.

How big is your finishing room? Do you wish it was bigger? I keep thinking I need to make it large enough to put a large table in it, or whatever I might make, but I don’t want to take too much room away from the rest of the shop.

I love the idea of having those two pillars. I hadn’t thought of that. Of course anything you do like that makes the set up of the shop kind of permanent, and my shop is smaller than yours.

I see you have a vaulted ceiling, I did that too, with 10′ side walls.

Thanks for any reply,

Wags