We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

3 Classic Vises made with Pipe Clamps

Increase your

bench’s versatility

on a budget.

By Chad Stanton

As a professional woodworker,

leaving the comfort of my

shop to work on a jobsite is part

of the routine. I always take along

a portable bench that’s equipped

with three inexpensive vises made

with pipe clamps. They’re durable

and simple to operate. To build

them, all you need is some plywood

and construction lumber. Almost

any brand of pipe clamp will work.

These vises can also be adapted to

fit a larger, stationary bench, too.

|

Face vise. |

Click any image to view a larger version. |

|

Tail vise. |

|

Moxon vise. The Moxon vise is essentially a face vise |

Face Vise

|

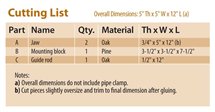

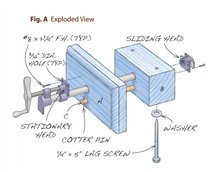

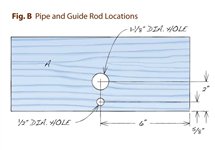

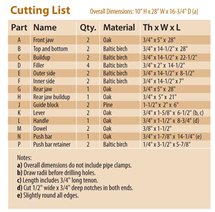

This is the simplest and most-used vise of the three. You can Cut the jaw’s pieces (A) slightly oversize, so you can true up To drill the vise’s holes, temporarily screw or nail the mounting Use a drill press to drill the holes for the pipe and guide rod To mount the vise to your bench, clamp the mounting With the clamp’s sliding head removed, insert the pipe and To adjust the vise, reach to the back of the mounting block Cutting ListFig. A: Exploded ViewFig. B: Pipe and Guide Rod Locations |

Squeeze the pipe clamp’s clutch plates to adjust the jaw in |

Tail Vise

|

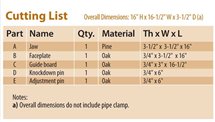

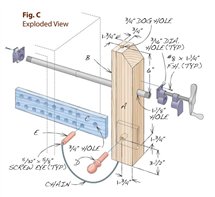

Like the face vise, first glue up the jaw (A) and faceplate Mark and drill the jaw’s pipe hole using a drill press. Also Clamp the jaw in position to your bench’s end. Using the Use a hand drill to make the pipe hole through the bench’s Drill the adjustment holes in the pin board (Fig. D). Drill screw holes in the clamp heads. Insert the pipe into Drill the dog hole in the jaw’s top, and a series of holes in Use the adjustment pin (E) to set the vise’s opening according I used a 16" pipe for this vise. Like the face vise, reach under Cutting ListFig. C: Exploded ViewFig. D: Guide Board Hole Pattern |

Insert the adjustment pin in the hole that gives you the |

Moxon Vise

|

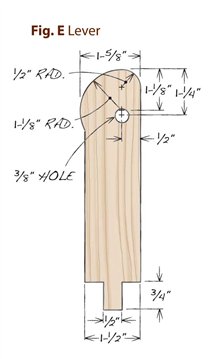

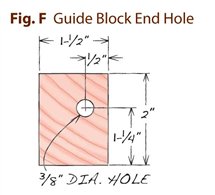

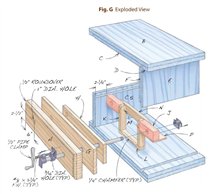

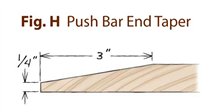

Named after 17th-century woodworker and author Another benefit of the Moxon vise is its height. It Unlike the other vises, I used 1/2" instead of 3/4" pipe A good vise must be extremely stable. I made this one To build the vise, glue up the front jaw pieces (A) Glue and screw the outer and inner sides (E and F) in Mark and drill the front jaw holes using a drill press Next, cut out the levers (K, Fig. E) and handle (L). After the glue dries, slide the guide blocks onto the dowels Before attaching the bottom, assemble the vise as Install the push bar retainers (P) and test the handle’s operation. Cutting ListFig. E: LeverFig. F: Guide Block End HoleFig. G: Exploded ViewFig. H: Push Bar End Taper |

Pull the handle towards you to release the clutch plates for |

|

This story originally appeared in American Woodworker August/September 2013, issue #167. |

|

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.