We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Carbide Cutterheads for Jointers

Cut manufactured

materials and

make fewer

knife changes

By Dave Munkittrick

|

The latest thing in jointers

Cost

At $300 to $400, segmented carbide cutterheads aren’t inexpensive. Replacing the inserts after all four edges are dull

Changing inserts

Rotating or changing the inserts is a somewhat

Segmented cutterheads take more power

I’ve noticed that the segmented cutterheads take |

Click any image to view a larger version. A segmented Carbide cutters allow you to joint abrasive manufactured materials, Changing carbide inserts is done less frequently and is less frustrating |

5 Big Advantages

1. Longevity. A single set of carbide inserts will outlast a conventional

knife set by approximately 40 times. That’s because each

insert is made of solid carbide and has four cutting edges.

Each edge will last up to 10 times longer than a typical HSS

knife-edge. Multiply that number by the four edges on each

insert and you get 40 conventional knife sharpenings built in

to each set of carbide inserts. Remember that when you’re

weighing the extra cost of a segmented carbide cutterhead.

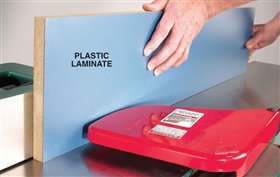

2. Jointing manufactured materials.

Carbide inserts allow you to joint manufactured materials,

such as melamine and MDF, which would instantly dull HSS

knives (photo at left). This is true of hard abrasive woods

like teak, too.

3. Easy knife changes.

With carbide inserts, knife changes are no longer such an

onerous task. No more fussing with knives

that creep out of position as they’re tightened down.

4. Less noise. A segmented cutterhead runs noticeably quieter than a

straight knife cutterhead. Anything that diminishes the noise

pollution in the shop is a welcome addition.

5. Quality of cut. Carbide inserts will make clean cuts much longer than HSS

knives will. We found that both carbide inserts and HSS

knives make beautiful cuts when the knives are sharp.

However, the performance curve drops off rapidly with the

HSS knives simply because they dull more quickly.

|

This story originally appeared in American Woodworker September 2005, issue #116. |

|

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.