|

If you can't stand throwing away good wood, you've probably

got a stack of short boards that are

just waiting to become–who knows

what? I've turned my stack into a

library of wood samples, which can be

shelved just like real books.

My wooden books are ideal for

showing customers and friends what

different kinds of wood look like, and

how a wood’s figure varies depending

on how boards are cut.Having made

the books years ago, I also now have a

record of how a wood's natural color

changes with time and exposure.

To make a book, start by milling a

blank foursquare. If you’re using rough

lumber, start with a blank that’s at least

12" long, for safety when jointing and

planing.The blank can be any thickness,

but I've found that books 1" thick

or more look best. For your first book, a

milled 2×6 is just right.

Begin by rounding over one long

side of the blank (Photo 1). For books

that are 3/4" to 1-1/4" thick,use a 1/4"

radius bit; for books 1-1/2" to 2" thick,

use a 1/2" bit; for thicker books, use a

1" bit.

Rip the spine from the body of the

book (Photo 2).Make the cut 1/16”

below the base of the roundover.Mark

the two pieces so you can correctly reassemble

them later.

Saw the book's outer pages (Photo

3).An ATB (Alternate Tooth Bevel) style

blade gives the best look. I recommend

that you use a zero-clearance

fence for maximum support. Raise

the blade to make a cut 3/16" deep

and position the fence 1/8" from the

blade. To minimize tearout,make the

first cut with the book upright, leading

with the spine side. Next, make a second

cut on the long side. Then stand

the book upright again, and make a

third cut on the remaining short side .

Turn the book around, and repeat

these three cuts.

To cut the inner pages, raise or

lower the blade a bit, move the fence

1/64" less than the blade's kerf, and

repeat these cuts in the same order.

Continue to make a series of similar

cuts, changing the blade's height and

the fence's position by different

amounts each time,until all the pages

are formed.

Make a reveal between the spine

and body by chamfering the mating

edges of both parts (Photo 4). Spread

glue on the joint (use a small amount

so there's no squeeze-out to clean up)

and bind the book with rubber bands

(Photo 5).Apply a finish–or not–and

it's ready for the shelf.

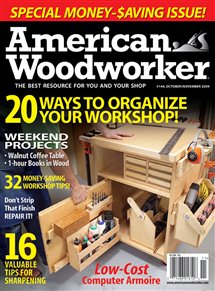

This story originally appeared in American Woodworker October/November 2009, issue #144.

October/November 2009, issue #144

Purchase this back issue.

|

|

Click any image to view a larger version.

1. Round over one side of a squared-up blank,

to duplicate the look of a book’s spine.

2. Rip the blank to separate the spine from

the body of the book.

3. Simulate a book’s pages by sawing three

sides of the blank.Vary the height and

width of the cuts. Caution: Use a push

pad to support the

work and to keep

your fingers away

from the blade.

4. Chamfer the edges of the spine and body

with a block plane.

5. Glue the spine back to the body.Use rubber

bands as clamps to avoid marring the

book.

|