We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Roll-Around Shop Cabinet

This wooden cavern holds tons of tools, plus it doubles as a bench outrigger.

By Ian Kirby

For tough and intelligent tool storage, it’s hard to beat a professional mechanic’s tool chest. It has shallow full-extension drawers tailored to the tools inside, it rolls around, and it’s indestructible. However, in the woodworking shop, the mechanic’s chest isn’t perfect: it’s expensive, it’s made of edge-dinging metal, the drawers aren’t sized for woodworking tools, and it’s not a useful height. This roll-around toolbox solves all of these problems.

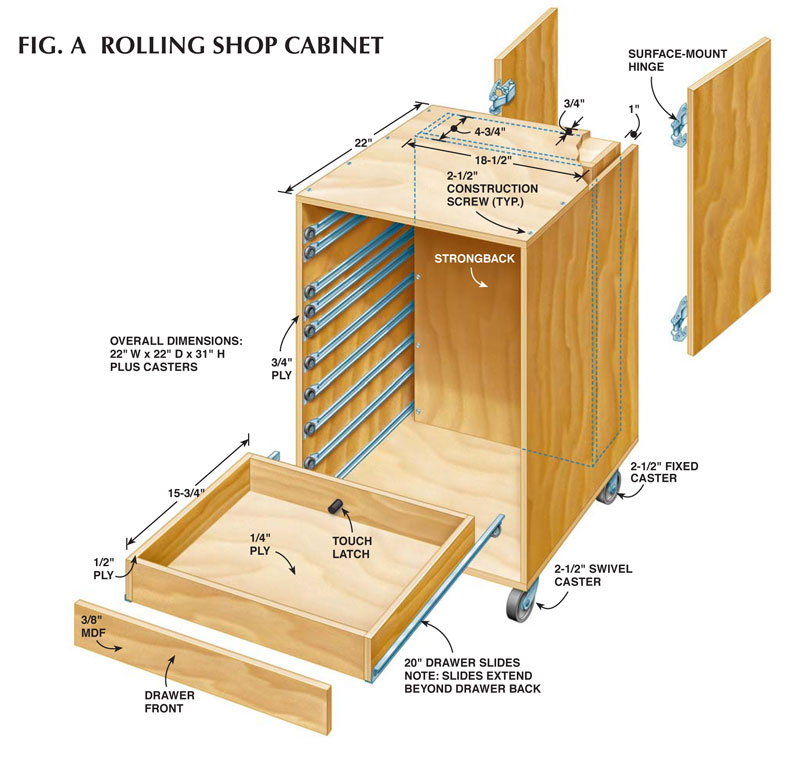

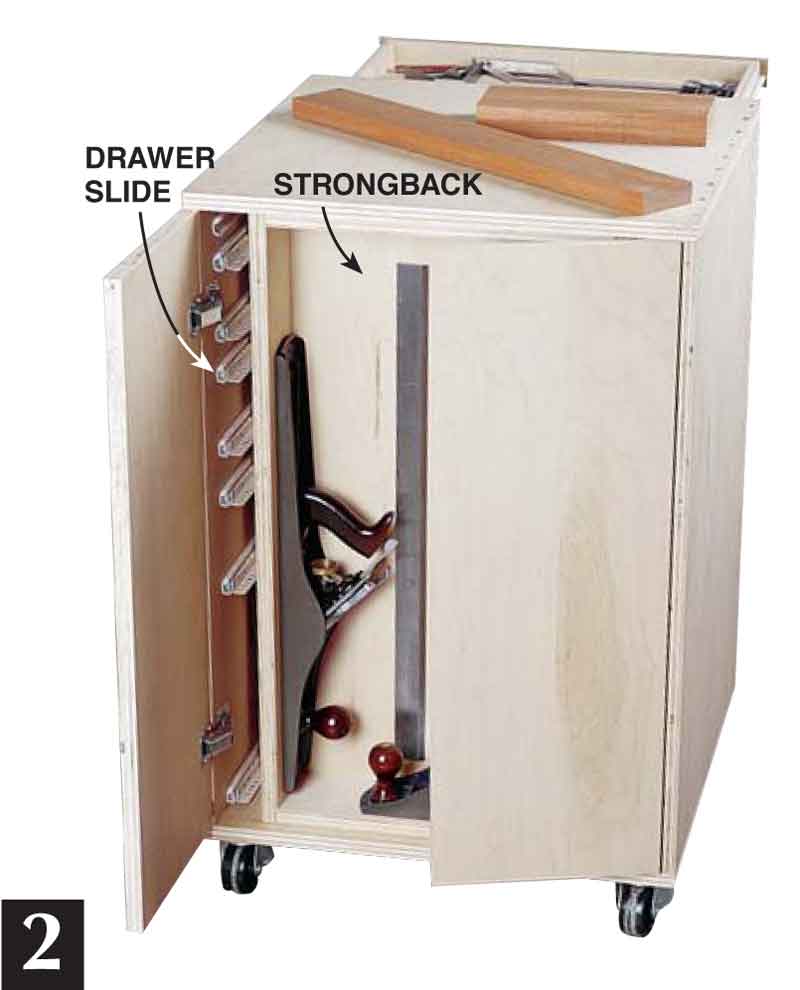

One nifty feature is that it has full-extension drawers without the premium price of full-extension slides. Instead, you use ordinary bottom-mount slides that are 4 in. longer than the drawers themselves. The extra length tucks into a pocket alongside the internal strongback (Photo 2). This approach easily saves you $100. To build the box, plan to spend about $80 on wood, and $75 on hardware.

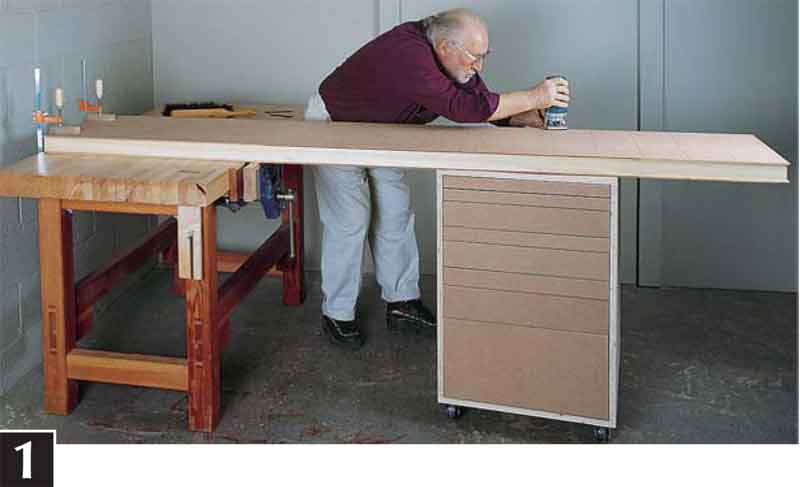

This toolbox works closely with your bench (Photo 1). It keeps your tools organized and close at hand, but out of the way of your project. By making the box the exact height of your bench, it also works as an outrigger for breaking down plywood and supporting large work. The compartment behind the drawers accommodates tools up to 28 in. long.

There is a tradition among woodworkers of making extremely fine tool cabinets, as a way for the traveling journeyman woodworker to display his or her abilities. There’s nothing wrong with following that tradition. But it’s not what I was after in this design. This toolbox is in no way a showcase. It’s a tough, utilitarian piece of shop furniture featuring exposed screw heads and naked plywood edges.

The big advantage to this design is that it doesn’t take a lot of time or money to make. Of course you could edge-band the plywood, use biscuit joints instead of screws, and paint the plywood, but there’s no functional reason for any of that.

Design your own drawers

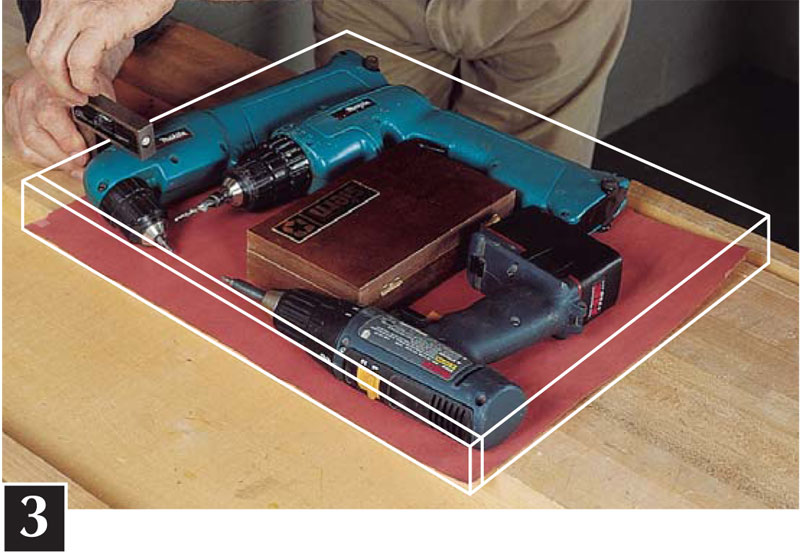

You’re the only one who knows what tools you have, so you have to design your own drawer layout. If you take a little time to do it, you’ll be able to fit an incredible number of tools into the box, and you’ll have them grouped to suit your needs. Quick access is important, and workshop space is precious, so think about what tools you use together, which ones you use all the time, and which rarely see daylight. Make a drawer template out of plywood or cardboard, so you can lay out each group of tools (Photo 3).

I like to keep my measuring tools handy, so I put them in the top drawer, with gauges and layout tools in the next drawer down. Some things aren’t compatible in the same drawer—chisels with files, for example. Spade bits and drill bits can lie down in a shallow drawer, but router bits should stand up in holes drilled into a block, so they can’t knock together. Group like tools together in shallow trays, with dividers to maintain order. TIP: You’ll maximize useful space by running dividers from front to back instead of from side to side.

Once you’ve planned your layout, it’s easy to dimension the drawer parts. To find the distance from one drawer bottom to the next, measure the height of the contents and add 1/2 in. for the bottom itself plus a little clearance. The drawer sides and ends can be as wide as the depth of the contents, and they can be a lot narrower, too—routers and other big tools sit very well on shallow trays.

The top drawer should have sides that are about 1/2-in. narrower than the drawer opening, so the drawer can be tipped up for installation.

Draw before you saw

Don’t charge into sawing your plywood before you buy the hardware. You can cut wood to suit the hardware, but you can’t redesign metal hardware to fit your wood. Get all the hardware—drawer slides, hinges, touch-latches and wheels—before you start to build, then adjust your design to suit these parts.

You’ll have to make a full-size sectional drawing to show how the drawers fit inside the case. The drawing will help you avert hardware conflicts. Pay close attention to the back-door hinges. You might have to rearrange the drawers to make room for them.

Magnetic touch-latches bypass the need for drawer pulls and keep the drawers closed while you roll the cabinet around the shop. Single latches won’t have enough oomph to open deep drawers full of iron, but you can buy double latches, or combine two or more singles.

Assemble the box

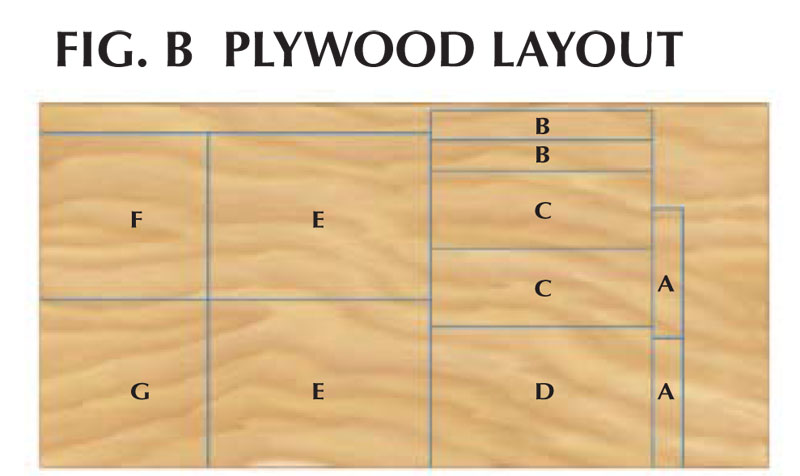

Figure B shows how to get the whole box out of one sheet of 3/4 in. plywood. Note that seven pieces—the box sides, the rear doors, the strongback sides and back—are all sawn to the same height. Organize the plywood breakdown and sawing so you complete all seven pieces at the same fence setting, then trim off 1/8 in. from the rear doors, so they’ll close easily.

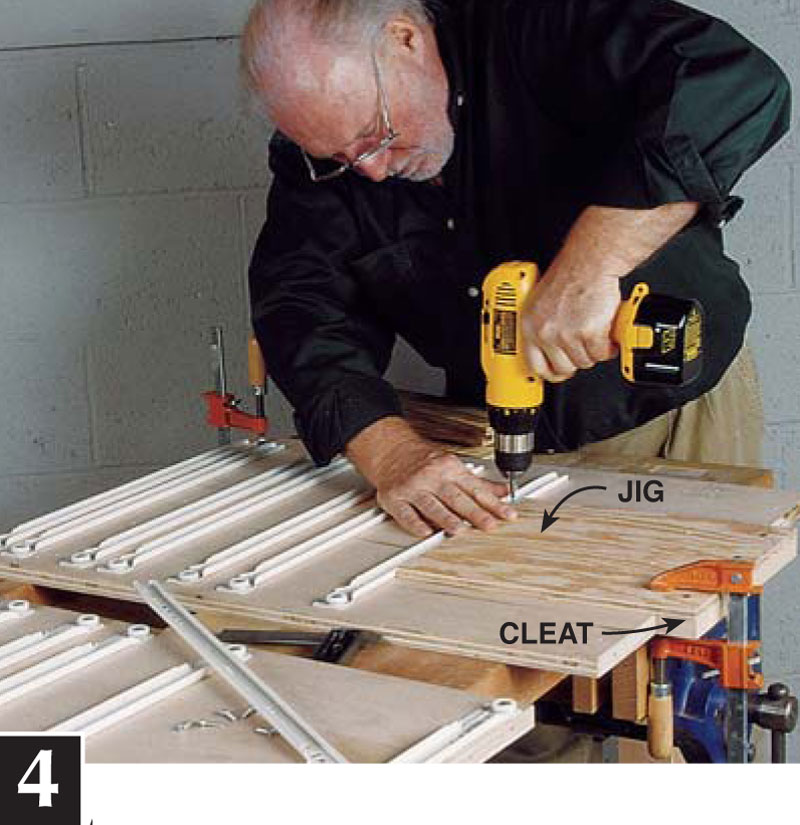

Mount the drawer hardware on the plywood sides before you assemble the box, using the locator jig, shown in Photo 4. The jig shown consists of a piece of plywood with a cleat at one end. The top of the slide should sit tight against the bottom end of the plywood jig. Saw the depth of the next drawer off the jig after each pair of slides, to prepare it for the next pair. Saw the exact distance from the bottom of one drawer to the bottom of the next.

I assembled my toolbox with 2-1/2 in., No. 8 Phillips-head construction screws spaced about 3-in. apart. Lay out the location of the screw holes on the plywood top and bottom, so you can drill and countersink clearance holes with the plywood flat on the bench. Set up the first joint with the aid of clamps, as shown in Photo 5. Be sure to drill the pilot holes into the second piece of plywood. If you skip this step, the entering screw will make the wood bulge, interfering with a tight connection. Make the strongback in exactly the same way.

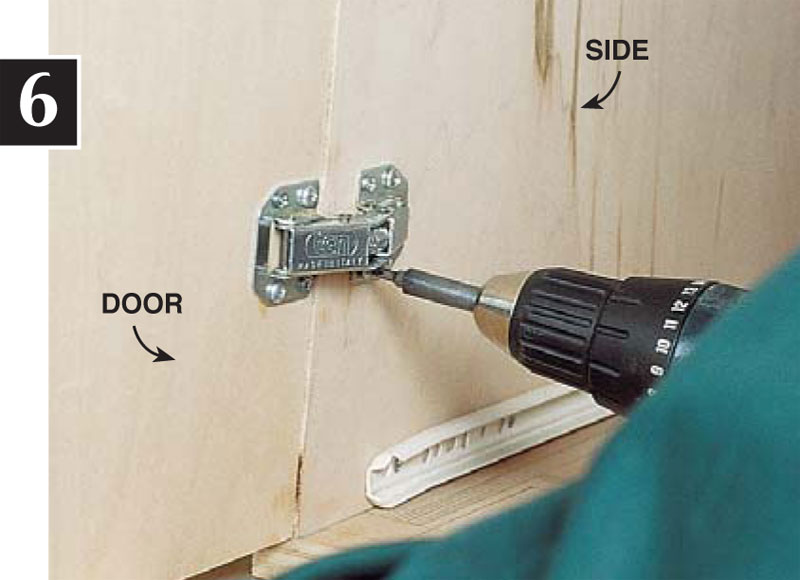

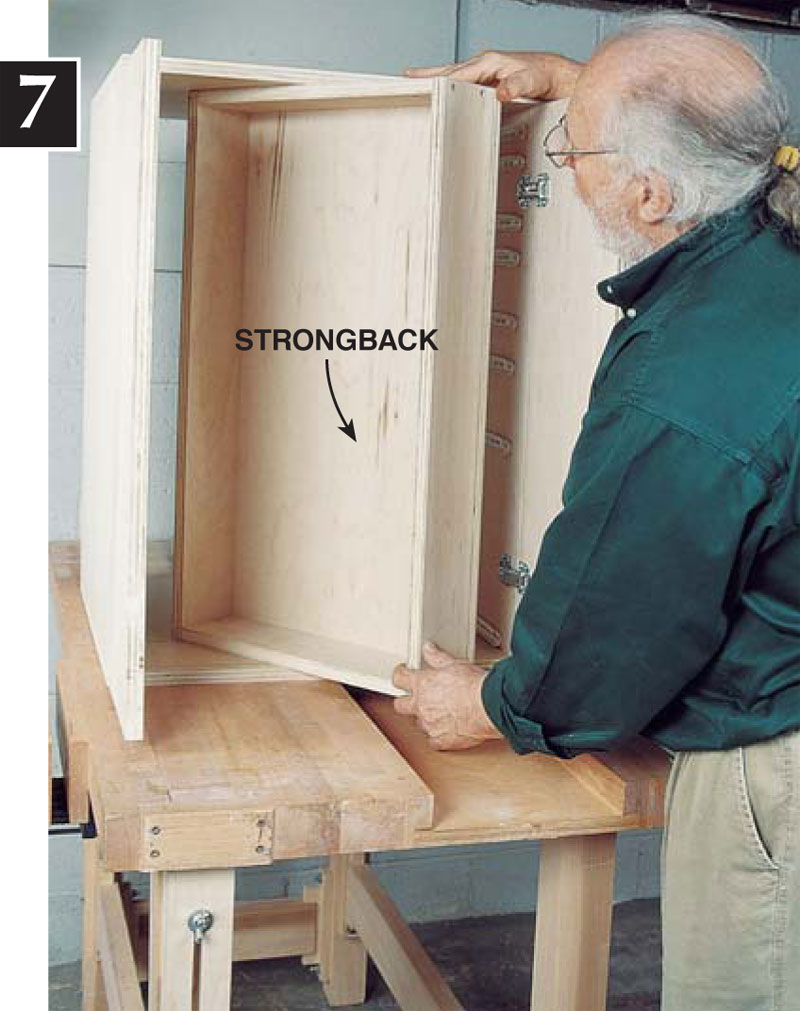

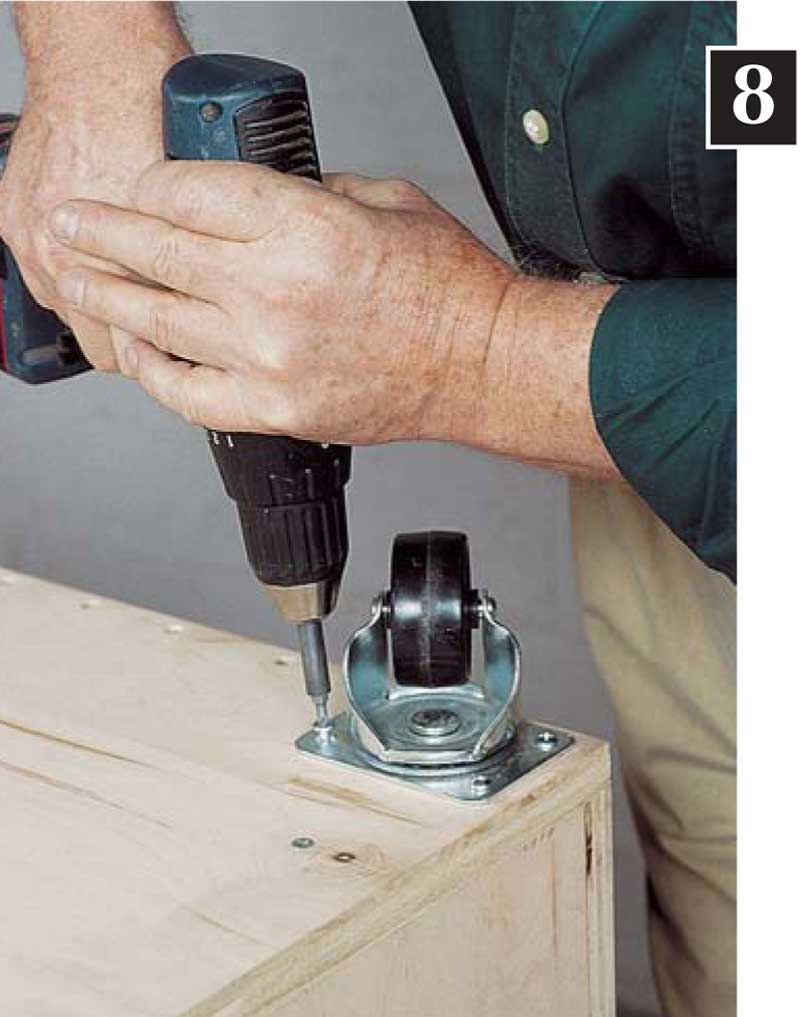

The screws don’t make a rigid cabinet, but the strongback takes care of that. First, however, mount the hinges on the doors and screw them to the box sides, because you won’t have easy access afterward (Photo 6). Then slide the strongback into the box and screw it to the top and bottom (Photo 7). Its edge sits 3/4 in. inside the box, so the doors can close against it. Once you glue the strongback, the box will not come apart again, so don’t glue it until you’re sure everything is in the right place. Add the casters (Photo 8), and the box itself is done.

Make the drawers

The toolbox features a straightforward plywood drawer. Saw the sides and ends from 1/2 in. uniform laminate or Baltic birch ply. Strength and squareness comes from the glued-on bottom, which is 1/4 in. ply.

To assemble the drawers, screw or nail the sides and ends together. Lay down a uniform coat of glue on the bottom edges of the drawer, then place the bottom on the glue. Line up the corners, and nail it all around (Photo 9).

Close-fitting drawer fronts will help keep shop dust out of the box. I made these drawer fronts out of 3/8-in. MDF with a 3/16-in. roundover; solid wood works as well. The fronts are 3/4-in. wider than the drawer itself, and 1/8-in. higher. Because standard drawer slides need a 1/2-in. space on either side, this gives you 1/8 in. clearance each way. The false front fits flush with the bottom of the drawer, so there’s also 1/8-in. top clearance.

Start attaching the false fronts around the middle of the case (Photo 10). Position the first one by measurement and you will be able to do the rest by eye. Glue and clamp the fronts to the drawers; if you have an air nailer, you can glue and nail without bothering with clamps.

If you like this toolbox, consider making more than one. You could size the drawers for portable power tools, router bits, wrenches, screwdrivers and other machine-maintenance tools, or for supplies like sandpaper and finishing materials.

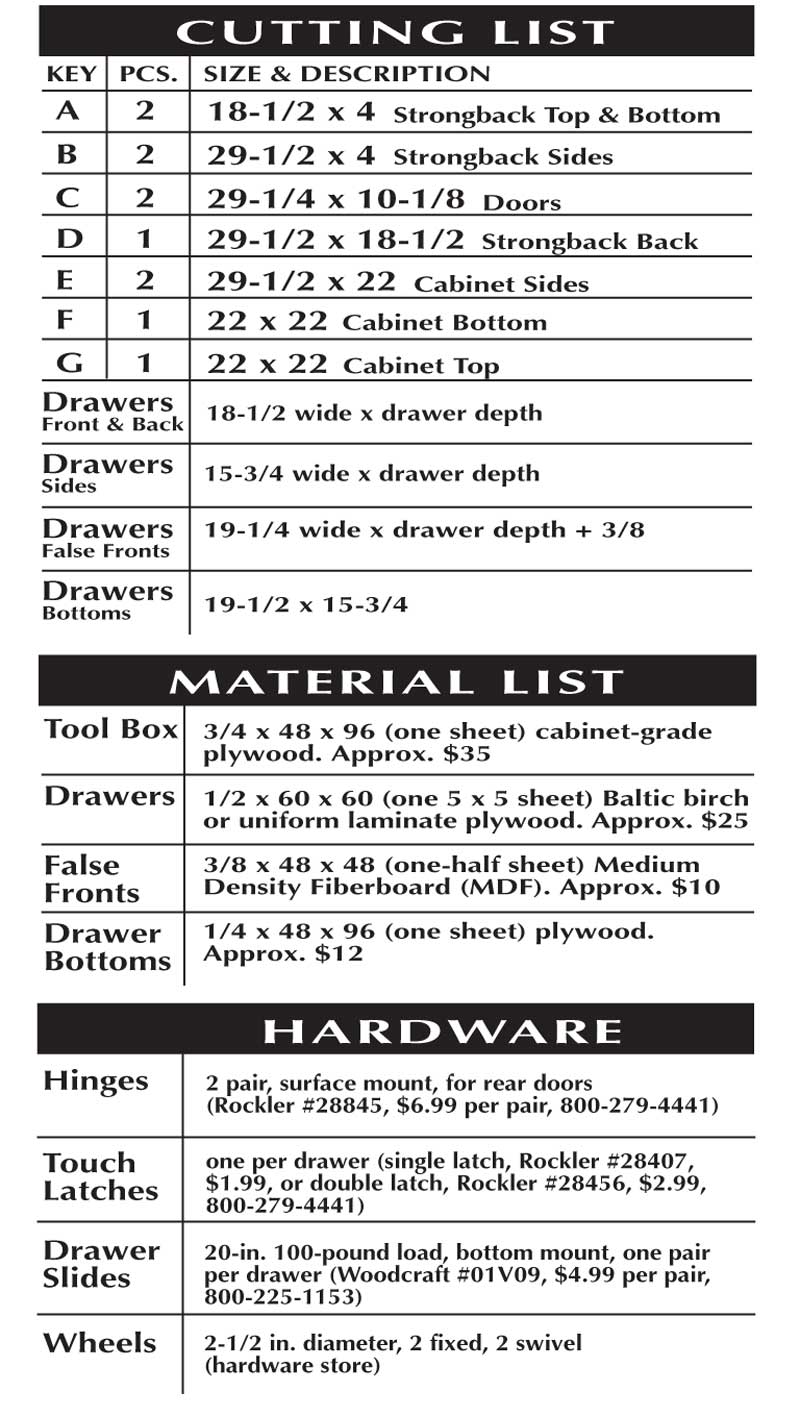

Cutting List, Material List, Hardware

Fig. A: Rolling Shop Cabinet

Fig. B: Plywood Layout

Click any image to view a larger version.

1. Use it as a work support. If you make the box the same height as your workbench, it’s easy to support a piece of plywood for cutting. Because of its width, the toolbox gives generous support to the cutoff piece. Drawers have touch-latches so there are no protruding handles.

2. Back doors reveal storage for longer tools in the “strongback”—a shallow box-inside-abox. Because the drawer slides extend back alongside the strongback, the drawers are essentially full-extension, without the expense of full-extension slides.

3. Design the drawers to hold your tools. A piece of cardboard the same size as the drawer bottom helps.

4. Mount the slides onto the sides of the toolbox before assembly. A plywood jig with a cleat will ensure that the slides are square and at the same height on both sides.

5. Drill and countersink the sides, and drill pilot holes in the top and bottom pieces. A piece of scrap clamped alongside ensures that the joint is flush. Screw the box together.

6. Hang the back doors with surface-mount hinges. Screw them to the doors first, then screw the doors to the box.

7. Insert the strongback and screw it on top and bottom. Its edge should be set 3/4 in. back so it acts as a stop for the doors.

8. Mount the casters, two fixed and two swivel. This allows for easy steering but some rigidity if you use the toolbox as a work support.

9. Drawers are simple boxes, butt-joined, glued and nailed, with a glued and nailed plywood bottom. The bottom makes the drawer rigid and square.

10. Glue false fronts to the drawer boxes after the slides are screwed on. Use clamps, nails or screws to hold the fronts while the glue sets.

This story originally appeared in American Woodworker April 1999, issue #72.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.