We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Perfect

Edge Joints

A 6-step

tune-up

sets your

jointer

straight.

By Dave Munkittrick

Jointers are simple machines with

few moving parts, but the two

beds, the fence and the cutterhead

all have to be in alignment

for a jointer to function properly. Few

things are more frustrating or more

common than problems with jointers.

This is especially true when you’re

trying to get straight, square edges

on your boards. I’ve come up with a

six-step tune-up that should set your

jointer straight. It’s easy to do and will

only take an hour or two, depending

on how many problems you unearth.

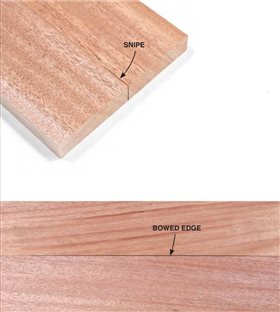

Jointers are supposed to cut straight,

square edges, but all too often, they

leave a sniped or a bowed edge (see

“Common Problems,” page 2). Snipe

results whenever the top of the outfeed

table dips below the knife’s top cutting

arc. A bow cut results whenever the

outfeed table rises above the cutting

arc. A cutterhead that’s not parallel

to the outfeed table, or tables that are

not parallel to each other, will make it

impossible to get the table height set

just right for all fence settings.

Common Problems

Our tune-up will help you identify and

correct four common jointer problems:

|

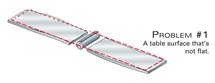

Problem #1:

A table surface that’s

not flat.

Problem #2:

Tables that are not

parallel to each other

across their widths.

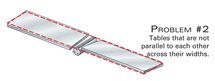

Problem #3:

Tables that are not

parallel to each other

along their lengths.

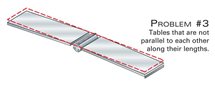

Problem #4:

A cutterhead that’s

not set parallel to

the tables.

|

|

Click any image to view a larger version.

Common jointer

problems result

in a sniped or

bowed edge.

Adjusting the outfeed

table height usually

cures the problem.

However, if both tables

and the cutterhead are not in

perfect alignment, the problem

will return when you move the

fence. This tune-up procedure takes

care of all the possible misalignments

that can cause jointer problems.

|

The Right Stuff

You will need a few tools to perform this tune-up: A good

straightedge, a set of feeler gauges and machinist’s metal

shims are must-haves for this job. For some steps, a dial indicator

is easier to use than a straightedge.

The straightedge, shims and feeler gauge run about $105

total. The optional dial indicator with a magnetic base

and extension arms adds another $40 and is well worth

the cost. All these tools can also be used to set and

tune-up other shop equipment and to check your own

work for flatness (see Sources, below).

A precision straightedge is essential.

You can perform all the tune-up steps using

this 50" precision straightedge that costs $79. Unlike

inexpensive straightedges, this one has a precisionground

edge with a tolerance of .003" along its entire

length. Such a good straightedge is not cheap, but it’s a

good investment for your shop.

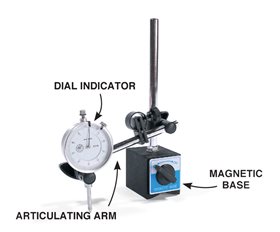

A dial indicator with magnetic base and

arm can’t be beat for tool setups. A number

of these six tune-up procedures are

best done using a dial indicator. Like the

straightedge, this tool is also useful for

other machine setups.

A feeler gauge set is used in tandem

with a straightedge to measure

very small gaps. If the straightedge

reveals a gap, you can measure that

gap by finding the feeler gauge that

fits under the straightedge.

Metal shims align jointer parts. Variety

packs are convenient and easy to use. A

strip of aluminum cut from a soda can is

a quick substitute for a .005" shim.

That coupled with some

.001" shim stock should cover

all your tune-up needs.

Shims can be stacked to create

any desired thickness.

Fine Tuning Your Jointer

Step 1: Check For Flat Tables and Fence

Check each table and the fence for flatness (Photo 1).

The accuracy of later measurements depends on flat tables.

Measure for dips or a droop using the straightedge held parallel

to the table bed. Then, hold the straightedge diagonally

across the table to check for twist. The good news is that finding

twist or dips in the table is highly unlikely. The bad news

is that if you do find things out of whack, you can’t do much

about it. In extreme cases, a messed-up fence or table may be

reground at a machine shop. You’ll have to weigh the cost in

time and money against simply buying a new jointer. If your

jointer is under warranty, talk to the manufacturer.

Step 2: Align Tables

It’s not unusual for the two tables to be out of parallel

across their widths (Photo 2). It’s easiest to check the tables

for parallelism with a dial indicator (Photo 3). You can also

do the check with a straightedge. Hold the straightedge

down on the middle of the infeed table so it extends over

the outfeed table. Set the infeed table to the exact same

height as the outfeed table. Slide the straightedge over to

the fence side of the table and use feeler gauges to check

for gaps. Repeat with the straightedge on the user side of

the table.

Align your tables by shimming the outfeed table.

Loosen the outfeed table’s gib nuts and lift the table so

you can insert metal shims on the side of the table that’s

low (Photo 4). Shim the outfeed table only because it is

moved very little and the shims are less likely to shift during

table adjustments.

Recheck the tables and make any necessary shim adjustments

until the tables measure in exact alignment.

Step 3: Fix Sagging Tables

Tables can also be out of alignment along their lengths

(Photo 5). Use the straightedge to see whether the table

end dips below the infeed table (Photo 6). Correct a dip by

adding shims to the top or bottom of both gib ways on the

outfeed table (Photo 7). Retighten the gib nuts and check

the tables again. Make any necessary adjustments until the

tables lie in the exact same plane.

Step 4: Level the Cutterhead

with the Tables

Now that the tables are parallel to each other along their

lengths and widths, it’s time to make sure the cutterhead

is parallel to the tables. If the cutterhead is not level with

the tables, your cut will be heavier on one side of the table

than on the other. Jackscrew cutterheads allow you to set

the knives to compensate for this; spring-loaded knives or a

segmented carbide insert cutterhead do not. The fix for this

problem is so simple that I recommend leveling your cutterhead

no matter what type of knife holder you have.

Use a dial indicator or straightedge to check cutterhead

alignment (Photo 8). If the cutterhead is off, measure the

exact amount on the low side. This equals the size of shim

you’ll need to raise the cutterhead (Photos 9 and 10).

Step 5: Set Proper Knife Height

To minimize kickback hazards, jointer knives should not

project more than .020" from the cutterhead. (Owners of

spring-loaded cutterheads have a knife-setting gauge that

automatically sets the proper knife projection.) A potential

hazard exists with knives set parallel to the outfeed table: It’s

easy to unintentionally set the knives so they project too far.

A dial indicator is the best instrument for checking knife

projection (Photo 11), but you can make do with a straightedge

and feeler gauge.

Step 6: Set Proper

Outfeed Table Height

Your knives should be set so that the very top of the cutting

arc, also referred to as top dead center, is the same

height as your outfeed table. We used the straightedge to

accomplish this task (Photo 12), but a dial indicator is another

option. To do this, set the dial indicator on the outfeed

table and zero it. Then set the plunger over the cutterhead

with the body of the indicator on the outfeed table. Rock the

cutterhead back and forth; the indicator should hit zero as

its highest mark. Check this at several points along the width

of the table. Repeat for all three sets of knives.

straightedge

no gaps

outfeed

table

knife at top

dead center

Edge-joint a couple of boards to test your jointer (Photos

13 and 14). In practice, it often takes a little tweaking of the

outfeed table height to get it just right. Often the table ends

up set .001 or .002" below the cutterhead. Now your jointer is

ready to go and should create perfect edge joints every time.

|

|

1. To start your tune-up, check each table for flatness. Lay

the straightedge on a table and use the feeler gauge to

check for gaps. A gap of .003" or less is acceptable.

2. Infeed

and

outfeed

tables that are not in the same

plane across their widths need

to be made coplanar. (With any

luck, your tables aren’t this bad.)

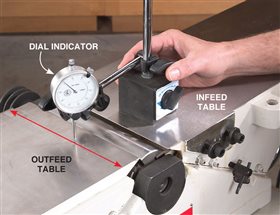

3. Check the tables for parallelism across their widths.

Bridge the dial indicator from the center of the infeed

table to the center of the outfeed table and zero it. Slide the

indicator across the width of the table to measure any difference

in height.

4. Bring the tables into alignment by inserting metal shims

on the low side of the outfeed table. Choose a shim

thickness equal to the amount your table was off. Loosen

the gib nuts and lift the table while you insert the shim or

shims. Then retighten the gib nuts.

5. Tables can be

out of parallel

along

their

lengths.

Typically,

the tables

sag on

the ends.

This is especially true on

older jointers that have

worn gib ways.

6. Check for table sag by holding a straightedge

tight against the infeed table. Set the infeed table

height so the straightedge just contacts the outfeed

table. Then use a feeler gauge to determine the

amount of dip or rise in your outfeed table.

7. Correct a sagging table by shimming the bottom

end of the two dovetailed gib ways on the outfeed

table. A table that dips toward the cutterhead would be

shimmed at the top end of the gib ways.

|

|

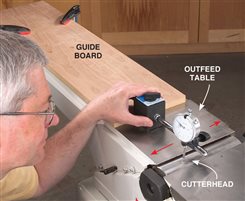

8. Check that the cutterhead is parallel with the tables. Rotate

the cutterhead so the knives are below the table. Clamp a

guide board parallel to the cutterhead. Set the dial indicator

against the guide board so the plunger contacts the cutterhead.

Zero your dial indicator; then slide it back and forth.

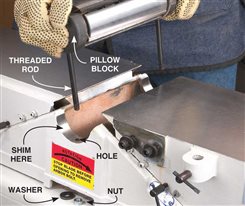

9. I removed the cutterhead here to illustrate how it is

mounted. Two threaded rods attached to pillow blocks

run through holes in the base and are held in place by a

nut and a washer. Place shims between the pillow block

and the jointer bed casting.

10. The cutterhead is easy to shim. Remove the drive belt

and loosen the bolts that hold the cutterhead in place. Lift

the low end of the cutterhead and insert shims under the pillow

block. Then retighten the bolts.

11. Proper knife projection increases jointer safety by limiting

the cut’s aggressiveness. Use a dial indicator set to zero

on the cutterhead. With your hand on the pulley, rotate the cutterhead

backward. As the knife rides under the dial indicator, it

should read no more than .020".

|

|

12. To set the outfeed table height, place a straightedge

on the outfeed table so it projects over the cutterhead.

Rotate the cutterhead backward and raise or lower the table

until the knife barely kisses the straightedge when it’s at top

dead center.

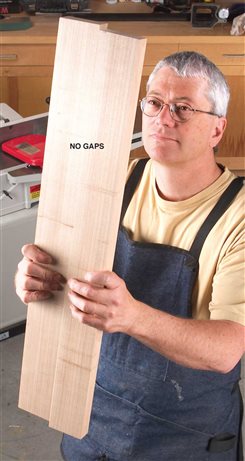

13. Fine-tune the outfeed table height by edge-jointing

a couple of boards that are narrower than the fence

height and no longer than the infeed table.

14. Put the newly jointed edges together and hold the joint

up to a light source. No light leaks indicate a jointer

that’s perfectly tuned. If you are getting a snipe at the end of

your cut, raise the outfeed table a bit. If the jointer puts a concave

edge on your board, lower the table. Repeat the process

with the fence set at the far edges of the table. The results

should be the same, and that should put a smile on your face.

|

Source

Note: Product availability and prices are subject to change.

Lee Valley Tools, leevalley.com, 800-871-8158, 50"

aluminum straightedge, #05N63.05; Dial indicator and magnetic base

and arm, 88N31.20; Feeler gauges, #86K99.01; Brass

sampler, 6-1/2" x 6", .001 to .010 thickness, #27K07.50.

This story originally appeared in American Woodworker August 2006, issue #123.

Purchase this back issue.

|

|

|

Product Recommendations

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.