Pie safes like this one were once

commonplace. The pierced-tin panels

kept insects out while providing ventilation

for cooling baked goods.

Our version is built of solid cherry with

a simple, modified-Shaker style that blends

easily into most any decor. Adjustable shelves

and a pair of drawers make it a versatile storage

cabinet. The pierced-tin panels that once

cooled pies provide ventilation for a modern

sound system. Or, you can use this pie safe to

store clothing and take some of the pressure

off that overstuffed closet or bureau.

Biscuits make the joinery on this project

as easy as pie. If you’ve never made a project

of this scale before, or are new to biscuit

joinery, this is the perfect place to start. You’ll

need to know how to make stopped rabbets

for the back and dadoes for the drawers, but

hanging the flush-fit doors is a breeze with

no-mortise hinges.

Getting off to a good start

You’ll need a biscuit joiner, a tablesaw set, a

router with a 3/8″ rabbeting bit and a jigsaw

to complete this project. With the exception

of the drawer bottoms and back, the

whole cabinet is made of solid cherry. One

of the tricks to using cherry is to be fussy

about your lumber. The color of cherry can

vary greatly (that’s why it’s often stained

dark by manufacturers). Select boards with

uniform color or ask that the wood you

order come from a single tree.

We spent about $900 on this pie safe.

You can shave off some of that cost by

punching your own tin. Now, let’s head for the shop.

Start with the wood

Sort your wood for grain and color. Most

cherry boards have some sapwood, the offwhite

wood found on the outer edge of the trunk. Plan your cuts so the sapwood is

kept to the inside where it won’t show.

Select flat, straight-grained wood for the

doors and face frame. This is one place

you can’t afford any warping. Cut the

drawer fronts (W) from a single board

so the grain flows from one drawer to

the next. Choose boards with compatible

figure and color for the sides (B)

and top (A). Use the less desirable pieces

for shelving.

Tips for better

biscuiting

-There are three common sizes of

biscuits: #20, #10 and #0. #20 biscuits

offer the greatest gluing surface and

are therefore the strongest. Use these

whenever possible even if it results in

the biscuit “breaking out” of the joint

(Photo 8). Breakout occurs on the face

frame and door frame where narrow

rails join the stile. But that’s not a problem

if you offset the center mark for the

biscuits so the breakout won’t be seen.

We did this on the face frame so the

biscuits break out where the drawers

and top cover them (Fig. B). Breakouts on the door frames are covered by the

tin panel stops. We offset the top-rail

biscuits to keep the top edge of the

door clean (Fig. C).

-Assembly with biscuits needs to

go smoothly because the biscuits

swell quickly once glue is applied.

For a more relaxed assembly, use an

extended-open-time glue like Titebond’s

Type II Extended or Liquid

Hide Glue (see Sources, below).

-Take the time to dry-fit each assembly

using all the biscuits and clamps

you’ll need for the real thing. You’ll be

able to rehearse your glue up and red

flag any misaligned biscuits.

-Getting glue in the biscuit slots can

be a bit messy. Just squirt a bead into the groove and spread it along both

side walls of the slot with a small glue

brush (see Sources, below).

The carcass

1. Lay out and cut the biscuit slots for

the top (A), sides (B) and shelves (C)

(Photo 1).

2. Dry-fit first then glue up and cut

to length.

3. Use the leg patterns (Fig. A) to lay

out the shapes on the bottoms of the

sides. Cut them out with a jigsaw.

4. Use a tablesaw to cut the rabbet

on the back rail (D) for the back (Z).

Use a router with a 3/8″ rabbeting bit

to cut the stop rabbet on the sides for

the back.

5. Lay out the fixed shelf locations on

the cabinet sides, then cut the biscuit

slots for the shelves and the back rail

(Photos 2 and 3).

6. Drill holes for adjustable shelf pins

(see Sources, below; Photo 4).

7. Finish-sand all the pieces starting

with 120-grit and working your way

to 320-grit for an oil finish. If you plan

to varnish, stop at 220-grit.

8. Dry-fit and glue the carcass using

four clamps and cauls for the shelves

(Photo 5) and a fifth clamp for the

back rail. Be sure the carcass is glued

up square.

9. Glue the drawer kicker cleats (J) to

the bottom of the lower shelf. If you

own a pneumatic brad nailer, tack the cleat in place first so it won’t slide

around when you apply the clamps.

(Brad nailers can be like a third hand

during assembly.)

The face frame

10. Lay out the face frame, as shown

in Fig. B.

11. Cut the biscuit slots (Photo 7)

and dry fit the face frame.

12. If you are mortising in your

hinges, now’s the time to lay out and

cut the hinge mortises on the inside

edges of the face stiles.

13. Lay out and cut the leg profiles

on the bottom of each stile (Fig. A).

14. Begin the glue up with the

drawer divider mullion (S) and the

lower rails (R). Then glue the rest of

the face frame together.

15. Trim the protruding biscuits and

finish sand.

Final assembly

16. Glue the face frame assembly to

the carcass. Tack the face frame in

position with brads before applying

clamps. Trim the face frame overhang

with a flush-trim bit in a router.

17. Center the drawer kickers (E)

in the drawer openings and attach

them to the kicker cleats with a 6 x

1-1/2″ screw.

18. Attach the drawer runner cleats

(H, Fig. D) with a brad, glue and

clamps.

19. Assemble the drawer runners

(F and M) and position them on

the cleats so they set 1/16″ into the

drawer openings (Fig. D). Attach

the runners to the front cleat only

(Fig. D). You’ll attach the back of

the runners later.

20. Attach the top (Fig. A).

21. Make the cherry quarter-round

molding (K and L) from a 3″ wide

piece of cherry. Round over the two

long edges with a router and a 3/4″

round-over bit. Rip the moldings off

the piece and cut to fit. Glue and nail

the front molding in place. Nail the

side moldings in place but only glue

the miter joint and the first couple of

inches at the front of the case. This will

keep the miter joint tight but still allow

the carcass to move with the seasons.

The doors

22. Use a tablesaw to cut the rabbets

on the back edges of the door rails (U).

23. Cut biscuit slots, dry-fit, glue and

clamp the door frames (Photo 8).

24. Finish the rabbets on the doors

with a router and a 3/8″ rabbeting

bit—this will also trim the protruding

biscuits. Square the corners with

a sharp chisel.

25. Fit the doors.

26. Make the door latch (N) and

mount it and the door stop (G, Fig. A.)

27. Make the tin panel stops (V) and

miter to fit in place, but don’t attach

them yet.

The drawers

28. Cut the dadoes and rabbets in the

drawer fronts (W) and sides (X).

29. Finish-sand the insides of the

drawer pieces, then glue and nail the

drawers together making sure they

are square.

30. Finish-sand the outside of the

drawers.

31. Attach the drawer runners to the

drawer runner cleat (Photo 9).

32. Drill holes for the door and

drawer knobs.

33. Attach the back with screws.

Screws allow you to easily remove

the back for finishing and you won’t

be accidentally driving nails through

the side of the cabinet.

The finish

34. Finish-sand the outside surfaces

and ease the edges.

35. Apply three coats of Danish oil.

36. Mount the tin panels in the

doors, hang the doors and attach

the knobs.

37. Attach the back and stand back

to admire your work.

Just think; food safes like this used

to hold biscuits; now they’re held

together by them!

Sources

Frank Paxton Lumber Company, paxtonwood.com, 800-522-3305, 4/4 Cherry, 100 bd. ft.;

1/4″ x 4′ x 8′ cherry plywood.

Titebond, titebond.com,

Titebond II Extended, 1 gal., $29.99;

Titebond Liquid Hide Glue, 16 oz.,

$13.99.

Highland Woodworking, highlandwoodworking.com, 800-241-6748, Small glue brush

(pack of 10), #166025, $2.50; 2-3/4″

Horizontal toggle clamp, #166105,

$11.99 ea.

Woodcraft, woodcraft.com, 800-225-1153, 1/4″ dia. brass

shelf supports (25), #27I11, $2.99;

Pewter no-mortise ball hinge,

#130191, $4.50 each.

Van ***’s, vandykes.com, 800-558-1234, 1-1/4″ dia. cherry

knob, #02032579, $1.79 ea.

Country Accents, piercedtin.com, 570-478-4127, Pierced-tin

panel, 10″ x 14″, $20 – $30 each, depending on the pattern.

Cutting List

This story originally appeared in American Woodworker April 2000, issue #79.

April 2000, issue #79

Purchase this back issue. |

|

Click on any of the images to view a larger version

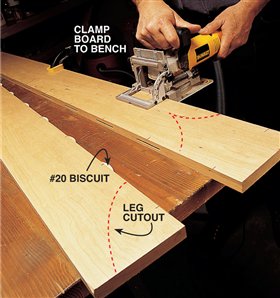

1. Cut the biscuit

slots about 6″ apart for

edge joining. The biscuits

align the surface of the

boards producing flush

joints that require little

sanding. You don’t want

to expose a biscuit

joint when making your

final cuts so keep your

biscuits at least 3″ away

from the ends of the

top (A) and the leg

cutout area on the

sides (B).

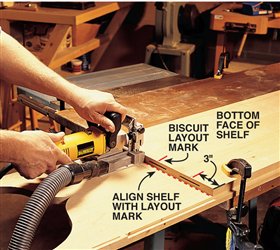

2. Cut the slots in

the end of the shelf

with the base of the

plate joiner on the

cabinet side. Clamp

the shelf on the side

so the top edge of the

shelf lines up with the

top edge of the layout

mark on the side.

Mark for biscuits in the

middle of the shelf and

3″ in from each end.

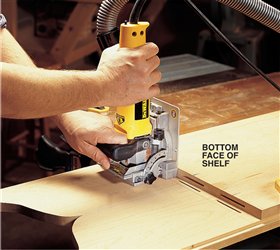

3. Cut the slots in the side with the plate joiner held

vertical and using the markings on the shelf.

Oops!

Somehow we managed to cut a biscuit where none belonged. A careless pencil mark can be mistaken for a biscuit mark when you’re cutting your way through a pile of frame members. Here’s how we fixed it: Use a compass to mark a 4″ dia. circle in some 5/32″ thick cherry and cut it out on the bandsaw. Glue the circle into the bad slot and clean up any excess glue. After the glue dries, flush-cut the repair.

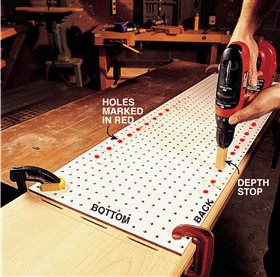

4. Drill for adjustable shelf pins using a perfboard

template. Mark the bottom and back edge to

correctly register the template on the other side of

the cabinet. Mark the holes to be drilled (every other

hole gives a 2″ spacing) and use a sharp brad-point

bit. Make your own fool-proof depth stop from 3/4″

x 3/4″ stock that’s drilled down the center and cut to

length.

5. Clamp the carcass assembly using shop-made

cauls to distribute clamping pressure across a wide

joint. See Photo 6 for

how to make cauls.

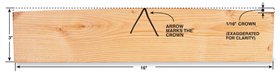

6. Make your cauls from 2x4s cut to the width of the cabinet. Make sure they are

well dried and all four sides are square. Plane or sand a 1/16″ crown on each caul and mark

the crown with an arrow. While you’re at it, make some extras and keep them for future use.

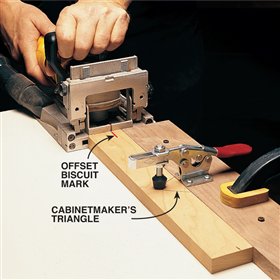

7. Cut slots in the ends of narrow parts, like this

face frame rail, using a simple jig to steady the work

and provide a wider surface for the plate joiner

fence. We used a 12″ x 30″ piece of melamine with a

3″ x 18″ piece of hardwood centered along the edge.

Add a couple of hold-down clamps (see Sources, below left). Note how the cabinetmaker’s triangle identifies

the piece being cut as the top rail.

The Cabinetmaker’s Triangle

Labeling your project parts with letters and numbers works fine when you’re dealing with a few pieces. But if your pile of parts gets mixed up it can take a while to sort things out again. The cabinetmaker’s triangle allows you to instantly identify the location and orientation of each individual piece. Here’s how it works: Group your frame members face-side up in the same orientation they will have when assembled (stiles are vertical, rails are horizontal, etc.). Mark each group with a triangle that points up towards the top of the cabinet. (With parts like the top and shelves, the triangle will point to the back of the cabinet). The triangle leaves two lines on each piece making identification a snap (See Figs. B and C, below). If two or more assemblies are identical, like our pair of doors, add an extra line along the triangle’s side for the rails and along the bottom for the stiles.

8. Assemble your door

frames on a perfectly flat

surface using identical clamps.

This helps ensure a flat door

and saves all kinds of headaches

later. Spacer sticks hold the

frame up off the clamps (so it

won’t get stained) and in line

with the clamp screw pressure

(so it won’t get twisted). Note

how the biscuits protrude

into the panel rabbets. They’ll

be removed later when the

rabbets are completed with a

router.

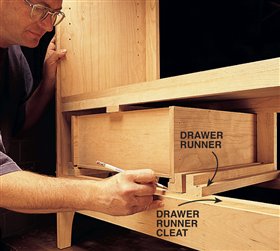

9. Mark the position of the

drawer runners on the

lower back support cleat. Have

the drawer in place with even

margins around the opening

and enough room between

the slides and drawer sides for

smooth operation. Remove the

drawer and fasten the runners

with screws.

Punch Your Own Tin!

You’ll save money and have fun

doing it. Everything you need is

available at Country Accents (see

Sources, at left):

10″ x 14″ tin blanks ($4.30

each); the pattern ($2); the hole

punch (T-0359, $5.95); and the

lampmaker’s chisel (T-0259-3/8,

$7.95). Expect to spend 30 to 40

minutes punching each panel. Don’t

try to do all six in a row or you’ll

feel like punching more than

tin. Take it easy and

spread the job over

a few days.

Wear a pair of

gloves when handling

the tin to keep from etching

in fingerprints. Tape the pattern

to the tin with masking tape. Use

pushpins to hold the work down

on a piece of particleboard and

have at it. Complete instructions

come with every order.

Fig. A: Exploded View

Fig. B: Face Frame Layout

Fig. C: Door Frame Layout

Fig. D: Interior Construction

|