Most woodworkers probably have a natural

aversion to working with plastic laminate. After

all, we love wood, not plastic! I managed to steer

clear of the stuff for years before a bathroom

vanity job forced me into it. I was surprised to find

it wasn’t so bad! I’d been missing out on a great

product that has a thousand uses beyond the

durable, easy-to-clean countertops found

in kitchens and baths.

Think Outside

the Countertop

Plastic laminate has a hundred uses

beyond the kitchen countertop.Around

the shop, it makes an ideal wear surface

for jigs, fences, extension tables, assembly

benches—anywhere a tough, easyto-

clean, low-friction surface is needed.

Unlike wood, plastic laminate

requires no clamping, sanding, staining, painting or varnishing.After machining,

you’re left with a perfectly smooth,

colorful and durable surface that’s ready

to use.

Plastic laminate not only creates a

durable surface, it also adds significant

strength. For example, a particleboard

shelf with a laminate top, bottom and

edge can hold three times the weight of

a raw, uncovered particleboard shelf.

Plastic laminate can also liven up

your projects with bold colors.Whether

it’s multi-colored shelving or a dark

green top on a walnut computer desk,

plastic laminates offer a broad pallet

of colors.You can even find some pretty

good imitations of leather and metal.

So, if you’ve shied away from working

with plastic laminate, it’s time to

get familiar with this durable and versatile material.

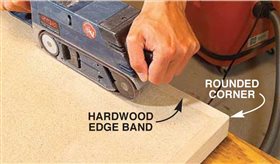

In this article we’ll walk you through

making a basic countertop with

radiused corners. We’ll also show you

how to make a countertop with a wood

edge.Laminate requires a few specialty

tools and some practice, but once you

master the skills, you may find yourself

choosing plastic laminate for countertops,

shop fixtures, doors—all sorts of

projects!

What Is Plastic Laminate?

Very simply put, plastic laminate is made

with layers of paper and resins pressed

together under high temperatures and

pressure to form a sheet about 1/16-in.

thick. The top layer of paper gives the

laminate its color.

Don’t mistake melamine for plastic

laminate. Melamine is really only the

single colored layer pressed onto one or

two sides of particleboard.Because the

colored layer is so thin,melamine does

not wear as well as laminate. Also, it’s

not available in as wide a selection of

colors, textures or patterns.

Many home centers carry plastic

laminate, but the choices are limited,

and the sheets are usually 4×8 and

smaller.However, you can special order

sheets up to 5 ft. x 12 ft., in a wide array

of colors and textures. (See Sources,

below for laminate manufacturer contact

information.)

Tip: Hang on to your leftovers.

Scraps of plastic laminate make

great shim stock for setting an even

gap around drawers and doors.

Choosing a Substrate

Plastic laminate is so thin, the surface

underneath it (the substrate) must be

sturdy and smooth. Because it’s relatively

cheap, the most popular choice

for a substrate is 3/4-in. high-density

particleboard. Medium-density fiberboard

(MDF) works equally well but

will cost you about 30-percent more.All

of these substrates are sold at home

centers in 4×8 sheets.

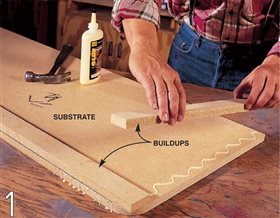

Build the Substrate

Make sure the substrate is perfectly

clean, flat and free of blemishes,because

they’re sure to show through the laminate.

Cut your top to size on the tablesaw.

Countertops typically have a builtup

edge to give them a more substantial

look.Cut 2-in.-wide strips of particleboard

for front-edge buildups. Glue

and nail (or clamp) the strips to the

outside edges for a full 1-1/2-in.-thick

nosing (Photo 1).Use a portable jigsaw

to cut a 2-in. radius on the outside corners.

Then sand the edges and radiused

corners perfectly even.

Cut the Plastic

Laminate to Size

Once your substrate is built, you’re

ready to cut the laminate sheet to size.

Full sheets of laminate are flimsy and

hard to handle. If you’re working alone,

we recommend cutting the sheets down

to manageable size using a scoring tool or a circular saw. You can also cut

laminate on your tablesaw using a simple

hold-down jig.

Cut the laminate 1/2-in. larger in width

and length than the substrate dimensions.

Cut the large surface piece first,

then the thin strip for the vertical edge.

Now you’re ready to cement the laminate

to the substrate. Remember, contact

cement works differently than other

adhesives. After coating both surfaces to

be bonded you let the cement dry before

you put them together. Once dry, the

two surfaces will bond instantly on

contact, and there’s no turning back.

You can’t reposition the piece.Weird

stuff,but it really is the best adhesive for

laminate work.

Apply the Laminate Edge

For countertops, always do the vertical

surfaces first and the top or horizontal

surface, last. That way the horizontal

top overlaps and protects the vertical

edge from chipping when you drag

heavy appliances or dishes off the countertop.

For vertical surfaces like doors,

it’s just the opposite; horizontal first

and vertical, or edges, last.

Position the substrate onto a couple

pieces of 1-in. scrap so the bottom of the

built-up edge is 1/4 in. off your bench

(Photo 2). This will accommodate the

1/4-in. overhang of the laminate piece

and allow you to use your bench as a

guide for getting the strip placed evenly

on the substrate.Apply contact cement

to the edge of the substrate and the

back of the laminate strip.

Let both surfaces dry to the touch.

Depending on the humidity, this could

take as long as an hour or as little as 15

minutes. Touch it with your fingertips

to test for dryness.The cement should

not stick to your finger. Keep the bottom

edge of the laminate strip in contact

with your benchtop to keep the

strip parallel to the substrate. Start at

one end and carefully press the laminate

strip to the edge of the substrate.

Don’t forget about those radiused corners!

When you’re a couple inches away

from the radius, grab your heat gun

and heat the laminate strip a few inches

on both sides of the radius (Photo 3).

Gently bend the laminate strip around

the curve and work your way to the

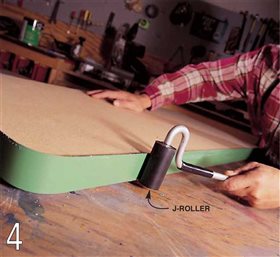

end.To ensure a complete bond, apply

pressure along the entire edge with a

J-roller (Photo 4).

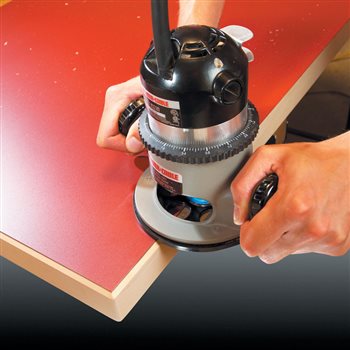

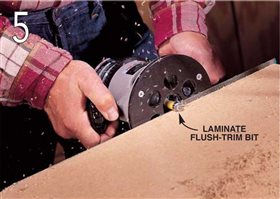

Flush-Trim the Overhang

Now you can trim the edges flush with

the substrate. Hang the edge of the

workpiece over your work surface to

allow room for the router base. Clamp

the countertop in place. Install your laminate

flush-trim bit in your router. Trim

the top and bottom edges (Photo 5).

Use a file or sanding block with 120-

grit paper to make sure the top and bottom

edges are perfectly flat (Photo 6).

Apply the Laminate Top

Double- and triple-check that the substrate

surface is completely clean! Even

the tiniest wood chip or bit of dust will

create a bump in the smooth laminate

surface. Coat the top of the substrate

and back of the laminate with contact

cement using a lint-free paint roller

(Photo 7). Cover it generously but keep it from oozing onto the edge face.

Wipe off any overflow with a damp

rag.When the cement is dry, place

clean, splinter-free slip sticks, about

4 to 5 in. apart,onto the substrate top

(Photo 8). Slip sticks can be 1/2-in.

dowels or square pieces of wood.

The slip sticks keep the two cement coated

surfaces from touching until

you get the top positioned precisely.

Flip the laminate onto the slip sticks

so you’ve got an even 1/4-in. overhang

all around.

Don’t get over-anxious with this

step. Starting in the middle, gently

pull out the slip sticks and press the

laminate onto the substrate. Work

your way to one end and come back

to the middle and work your way to

the other end.

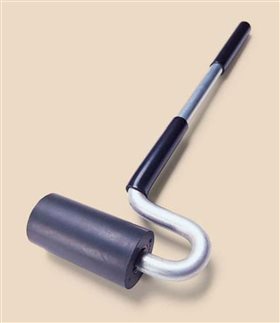

Use a J-roller over the entire surface

to ensure a good bond. Be careful

with the roller near the edges.

Getting too close to the overhanging

edge could snap the laminate (see

Oops!, below). If you don’t have a

roller, just wrap a cotton rag around

a 2×4 and push the edge of the covered

2×4 firmly over the entire area.

Trim the Laminate Top

Use a little mineral spirits on a rag

and rub any excess contact cement from the face of the laminated edge

until it’s perfectly clean. To protect

the vertical edge from burn marks as

you trim, cover the front edge with

masking tape. Keep the tape a hair

below the top edge (Photo 9).

Next, flush-trim the laminate with

your router. Note: Be sure there are no

burrs or loose screws on your router

base that could scratch the laminate.

Use a sanding block with some 220-

grit paper to remove burrs. Trim the

top, letting the bearing ride along the

taped edge (Photo 9). Move the

router from left to right, keeping the

base flat on the top.

Tip: If your trimming bit gets

clogged with contact cement,

you’ll need to clean it. Turn off

the router, remove the bit and

soak it in mineral spirits. Use an

old toothbrush to remove the

cement.

Ease the sharp top edge where the

laminate meets with a bevel-trim bit

(Photo 10). Install the bevel-trim bit

in your router so only 3/16 in.or less

of the cutting edge is exposed. Bevel

the top edge only. Now step back

and admire your work. |

|

Click any image to view a larger version.

1. Glue and clamp the buildups to the bottom of the substrate to give the

countertop a thicker, more substantial appearance. Use nails to pin the

buildups in place so they won’t shift around under clamp pressure.

2. Brush contact

cement on the

edges. Particleboard

edges which are

porous and may

require two coats (let

the first coat dry

about 30 minutes).

Brush contact

cement on the back

of the laminate strip

when you apply the

second coat to the

edge. Use supports to

hold the substrate off

the bench.

3. Use a heat gun on

curves to soften the

laminate. Press the

laminate onto the

substrate with a

gloved hand.

4. Roll the surface of the laminate firmly to ensure a good bond to

the substrate.

5. Trim the top

and bottom

edge of the

laminate strip

flush to the

substrate. Use a

laminate flushtrim

bit for this

job. Be careful not

to tip the router

as you cut.

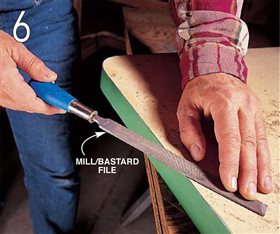

6. Smooth any

irregularities

left after routing

with a file or

sanding block. Be

careful not to

round over the

edge. File only in

the direction

that pushes the

laminate into the

substrate, not

away from it.

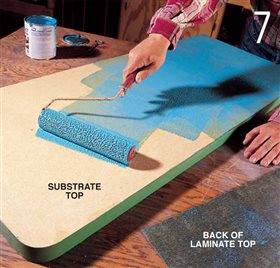

7. Roll contact

cement on

the substrate

and the back of

the plastic

laminate. Let it

dry on both

surfaces before

assembly.

8. Use “slip sticks”

to separate the

laminate from

the substrate.

Align the laminate

top with the

substrate, keeping a

1/4-in. overhang on

all sides.

Remember:You

won’t be able to

move the laminate

once it touches the

substrate. Start in

the middle and pull

out the slip sticks

one by one, pushing

the laminate onto

the substrate as

you go.

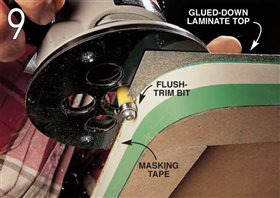

9. Trim the

laminate flush

with the substrate

all the way around

the top. Masking

tape protects the

laminate from

scorching should

the bearing get

clogged with

contact cement

and seize up.

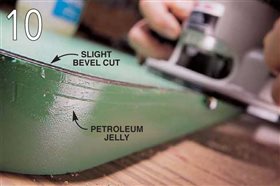

10. Use a beveltrim

bit to ease

the sharp edge

where the two

laminate pieces

overlap.A thin

coat of lubricant,

such as petroleum

jelly, protects the

finished edge from

scarring.

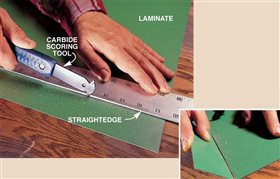

3 Ways to Cut Plastic Laminate

1. Cut the laminate with a

carbide-tipped scoring

tool. Make at least four

firm passes to score deep

enough for a clean break.

Pull up gradually from one

end of the score to the

other (inset photo).

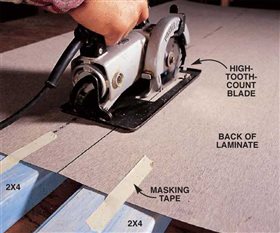

2. Cut the

laminate with a

circular saw. Set

the blade 1/4-in.

deep and hold the

laminate up off

your bench with

2x4s, as shown.

Use a high-toothcount,

carbide

blade in your saw.

Secure the

laminate face

down on the 2x4s

with tape.

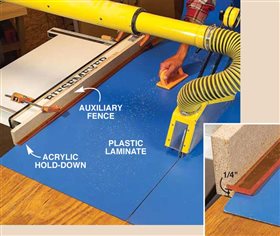

3. Cut laminate with a

subfence on your

tablesaw. The simple

subfence shown here fits

tight to the top of your

tablesaw so the laminate

can’t sneak under the

fence and get jammed.

A narrow strip of

acrylic holds

the laminate

down on the

table while

letting you see

where the

laminate

contacts the

fence. |