We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

It seats up to 8, but no one has to straddle a leg.

It seats up to 8, but no one has to straddle a leg.

Editor’s note: this article originally appeared in American Woodworker #154.

Every summer, my uncle Bob tends the grill at our family gatherings and is the last one to the picnic table. He always gets stuck with a middle seat. We’d cheer him on as he groaned and struggled to get into it—a lot of fun, but not a pretty sight.

Last fall, at our Labor Day feast, I resolved to build a new picnic table with seats that every person could slip right into. I call it the Crisscross, after the shape of its base. This one’s for you, Bob.

Crisscross Picnic Table Cut List

Hardware List

Hardware List

- 1 Box 4″ deck screws

- 1 Box 2″ deck screws

- 8 5/16″ x 3-1/2″ lag screws

and washers - 16 1/4″ x 3″ carriage bolts,

- with nuts and washers

- 4 1/4″ x 4″ carriage bolts, with nuts and washers

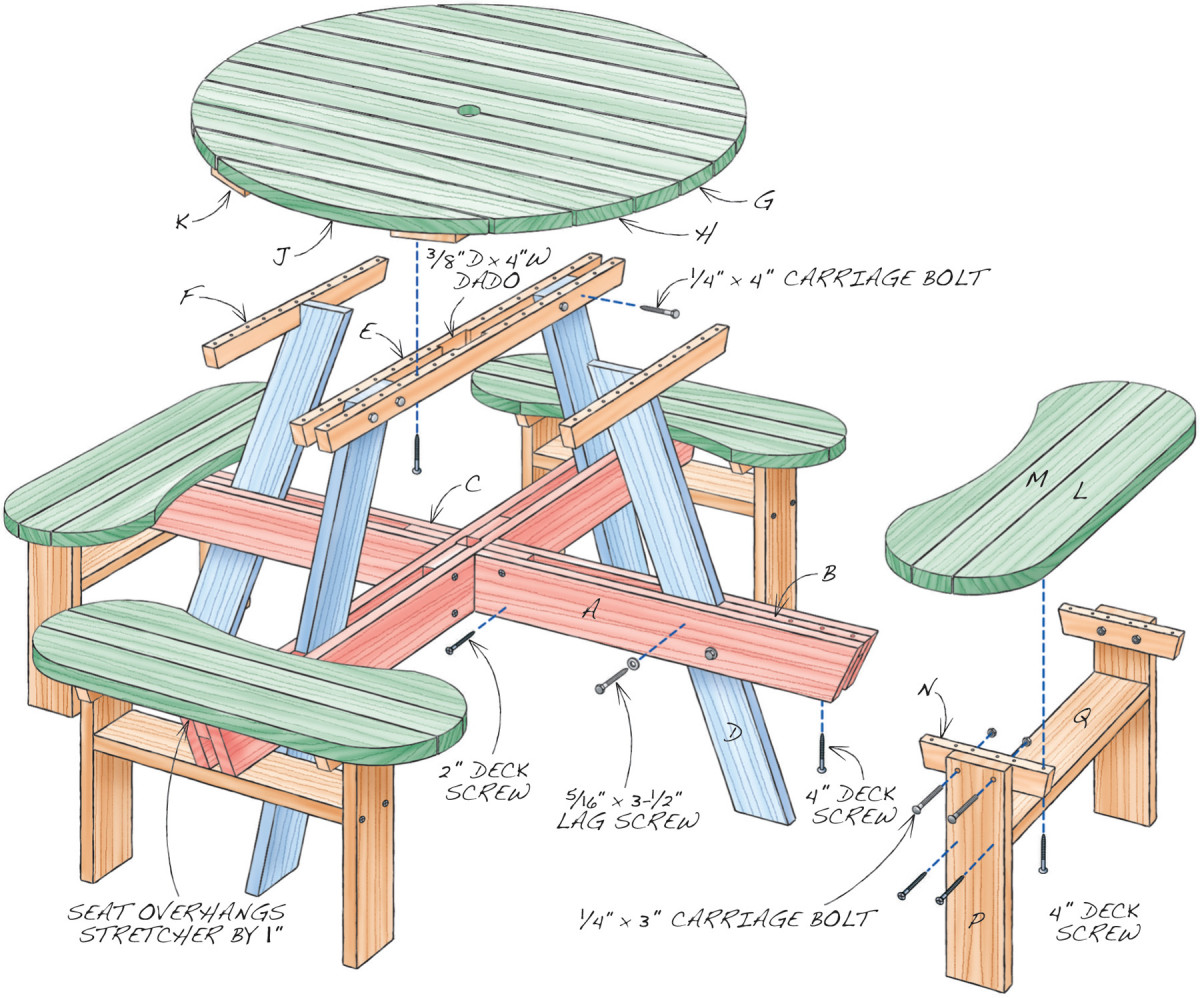

Fig. A) Exploded View

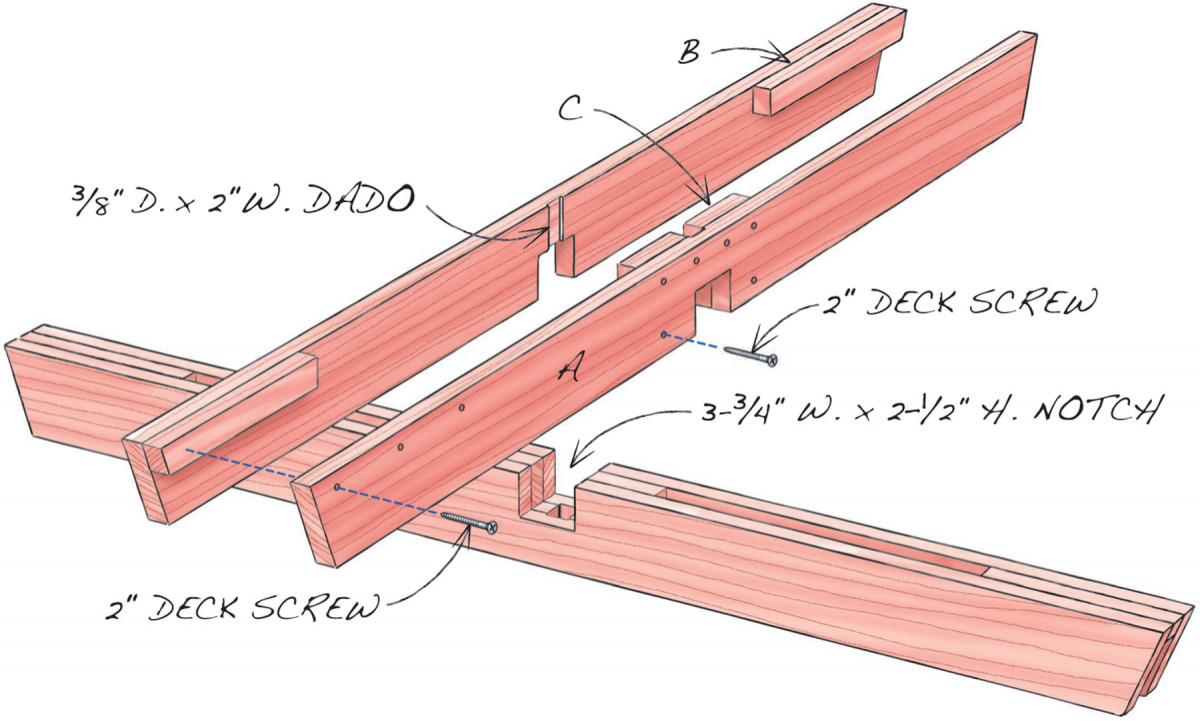

Fig. B) Stretcher Details

Fig. C) Stretcher Details

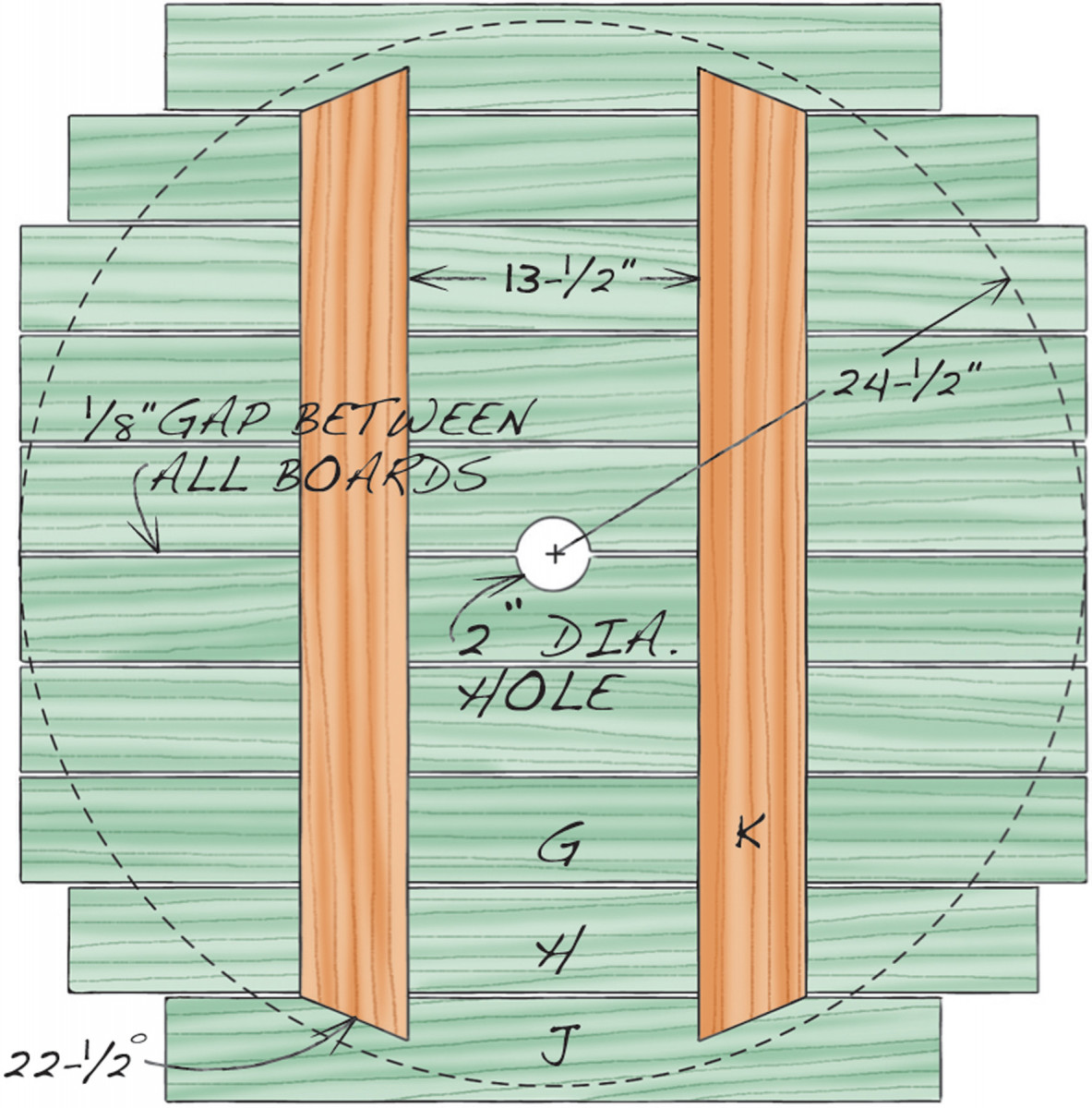

Fig. D) Top Layout

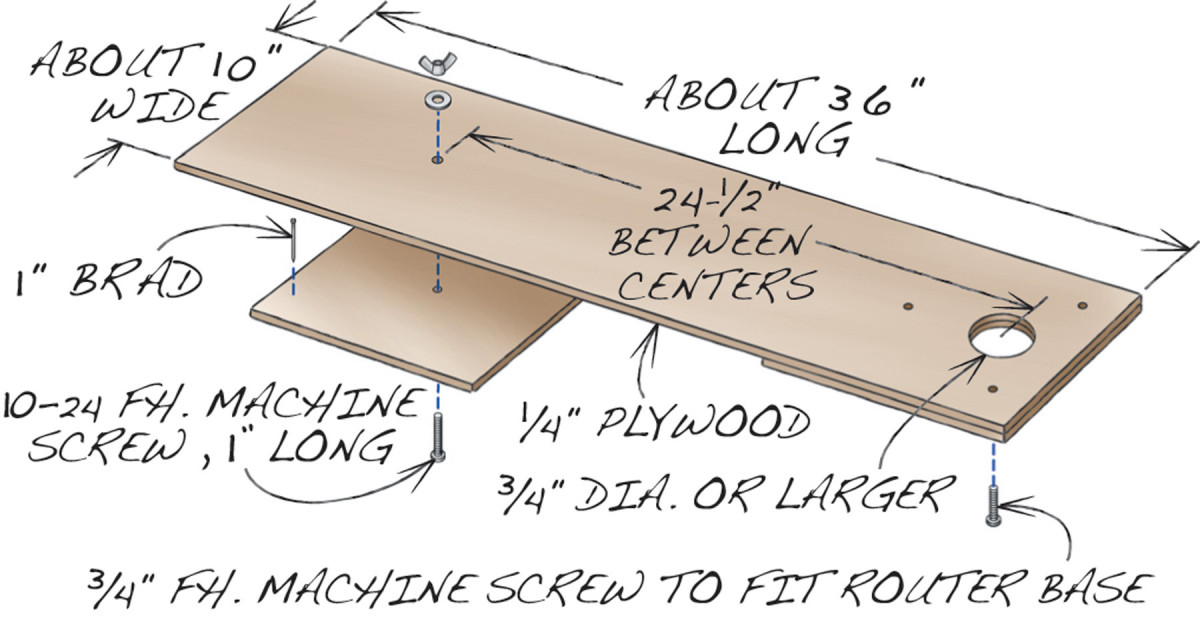

Fig. E) Trammel

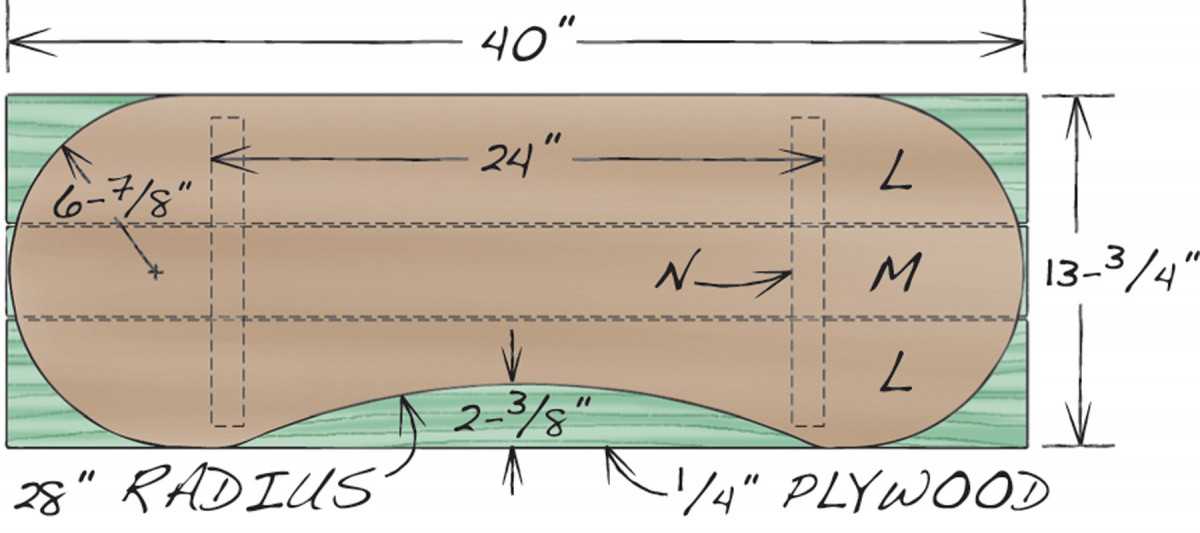

Fig. F) Seat Pattern

The wood

I started designing the table for standard 2×6 lumber, but one day a buddy suggested that I use a new material: thermally modified wood. It’s Southern yellow pine that’s been heated to a very high temperature, making it rot-resistant. The process also gives the wood a beautiful chocolate color, inside and out, which nicely complements our home’s cedar shakes and the artificial stone below it. The boards are amazingly flat and stable. I had to try it!

My friend builds decks for a living. He had a bunch of thermally modified wood left over from a job—enough to build this table. I gladly offered to buy it and had a great time working with it, although I did have to alter my plans a bit. The wood I used is thinner and narrower than standard material. (It’s 1-1/4″ thick and 5″ wide; standard boards are usually 1-3/8″ thick and 5-1/4″ wide.)

You’ll need about 24 pieces of 8′ long 2x6s to build this table. The cutting list will work fine if you’re using standard lumber, but your top will be nine boards wide, rather than ten. Let’s get going!

Build the cross stretchers

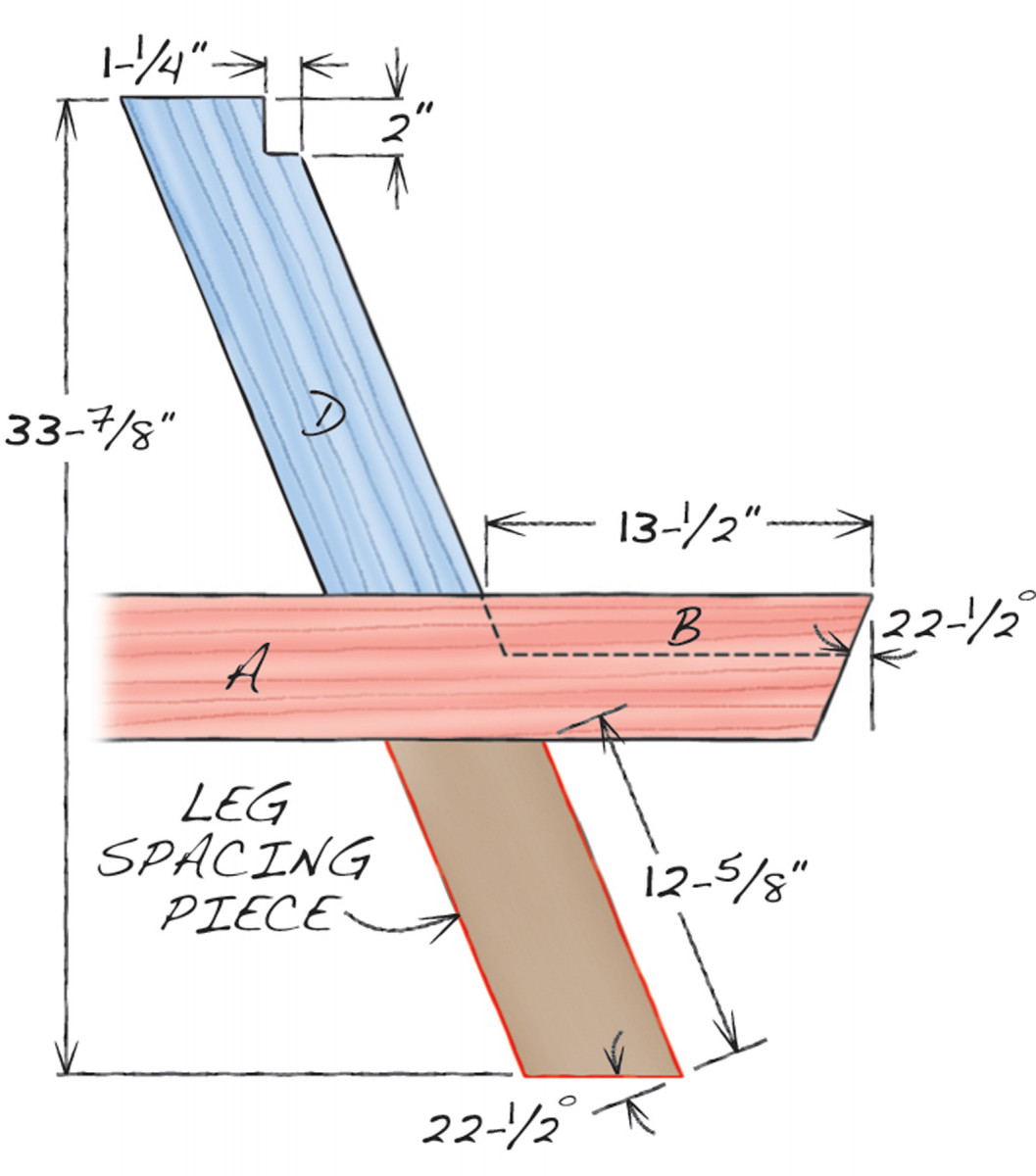

1. Cut the four crisscross stretchers of the base to the same length. Miter their ends at 22-1/2°. All miter saws have a detent for this commonly used angle.

Begin by making the crisscross stretchers (A). Saw them to length, cutting angles on their ends (Photo 1). Cut dadoes in the middle of each piece using a router or a tablesaw (Fig. B).

2. Glue and screw the stretchers together. Note the dadoes in the middle of each stretcher. These cutouts are needed to create a square hole large enough for an umbrella pole.

Make the pieces that go between the stretchers: the end spacers (B) and middle spacers (C). Using an exterior yellow glue, glue and screw these pieces to two of the stretchers. Sand all the mating surfaces first, so the glue will adhere better. (Note that the middle spacers are aligned with the sides of the dadoes you just cut.) Glue and screw a second stretcher on top of the spacers (Photo 2). You should now have two identical stretcher assemblies.

3. Cut half-lap notches in the center of each stretcher assembly. It’s best to use a crosscut sled, as shown here, to prevent this large piece from wiggling.

These assemblies will nest together with large half-lap joints. Draw these joints in the center of each assembly. When you lay out the joints, be sure that one notch will be on the top of the assembly and the other notch on the bottom. The angled ends are your guide as to which side is top and which is bottom. Cut the notches on the tablesaw (Photo 3). You can use a standard blade or a dado blade. (If you use a dado blade, don’t take off too much in one bite.)

4. Add two legs to each stretcher assembly. Use spacing pieces to make sure the legs are set at the correct angle and position. Use a long level to make sure the tops of the legs are even.

Make the legs (D, Fig. C). Notch the top of each leg as shown. Round over the bottom ends of the legs with a router. To help assemble the legs, make a pair of spacing pieces that are the same width and length as the portion of the leg that extends below the cross stretchers. You can use offcuts from the legs or pieces of plywood to make these pieces. Clamp the spacers to the bottom of the legs and insert the legs through the stretcher assembly (Photo 4).

Fine-tune the position of the legs by lining up their ends with a long level or straightedge. Once the legs are aligned, clamp them in place. Run two lag screws through the stretchers and the legs (Fig. A).

Finish the base

5. Fit the stretcher assemblies together. Use handscrews or blocks to hold one assembly upright while you drop the second assembly in place.

Join the two stretcher assemblies together (Photo 5). For maximum strength, use glue and screws. If you intend to take the table apart for moving or storage (or just to get it out of the shop!), skip the glue and screws.

6. Add braces to the legs for attaching the top. The long braces have dadoes cut in them to accommodate the umbrella pole.

Make the long braces (E) and short braces (F). Cut dadoes in the center of the long braces (Fig. A). These dadoes are oversized so you don’t have to be extremely fussy when positioning the braces. Glue and screw all four braces to the legs (Photo 6).

Add the top

7. Assemble the top. Place 8d nails between the boards to create equal gaps. Clamp the boards to keep them from shifting, then fasten cleats across the boards.

Cut the top boards (G, H and J) to length. Assemble them in a symmetrical pattern (Fig. D), using 8d nails or 1/8″ spacers between the pieces.

Note: If you’re using standard-width lumber to build this table, make the top from nine pieces, not ten pieces as shown.

8. Fasten the base to the top. It’s easiest to do this on a bench, with the base upside down. Before you begin, though, make sure you can get the table out through your shop’s door—it’s big!

Clamp the top pieces together (Photo 7). Make the top cleats (K) and glue and screw them to the top boards. Remove the clamps and place the base on the top. Fasten the base to the top (Photo 8). Get some help and turn the table over onto the floor.

You can use a jigsaw to cut the top into a circle, but a plunge router equipped with a long 1/2″ dia. straight bit will create a smoother surface. To guide the router, make a plywood trammel (Fig. E). Mark the center of the top and nail the loose square piece to the table. Remove the subbase from your router and fasten the router to the trammel. Place the trammel on the square piece nailed to the table.

9. Rout the top into a circle, using a plunge router mounted on a plywood trammel. First, plunge holes on both sides of each board to prevent splintering (see 9B). Then rout the full circle.

Set the router to make a plunge cut all the way through the top. To prevent the edges of the boards from splintering as you rout around the circle, make a series of plunge cuts on both sides of each board (Photo 9).

9B.

Then reset the router to cut one-third of the way through the top and rout a full circle. Reset the router to make deeper cuts and keep routing until you’ve cut all the way through. Use a 1/8″ dia.roundover bit to ease the top’s edge.

Add the seats

10. Make the seats. Fasten three seat boards together with cleats, like the top. Then nail a plywood template to the top of each seat and rout around the template, using a guide bushing in your router.

Make the seat boards (L and M) and seat cleats (N). Glue and screw the cleats to the boards (Fig. F). Make sure the cleats are parallel to each other—a plywood spacer would help here.

11. Fasten the seats to the base. This operation is much easier if the table is upside down, but you’ll definitely need help turning it over!

Make a 1/4″ plywood template for shaping the seats. Nail the template to a seat assembly (Photo 10). Use a plunge router equipped with a 5/8″ o.d. guide bushing and a 1/2″ straight bit to rout around the template. Round over the seats’ edges.

12. Add the legs and a stretcher. Now the seats will support plenty of weight—and even a few rambunctious kids jumping on them.

Fasten the seats to the base (Photo 11). Make the seat legs (P) and fasten them to the cleats. Make the leg stretchers (Q) and fasten them between the legs (Photo 12).

13. Rout a hole in the center of the table for an umbrella pole. Make a template with a hole in it to guide your router. Add the umbrella and pour the lemonade!

Drill or rout a hole in the tabletop for the umbrella pole (Photo 13). If you use a router, make a template with a 2-1/8″ dia. hole and nail it to the top. Use the same guide bushing and bit as you used for the seat.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

It seats up to 8, but no one has to straddle a leg.

It seats up to 8, but no one has to straddle a leg.