We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

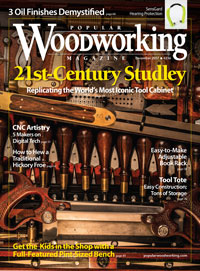

How five masterful makers integrate CNC and CAD technology into their woodworking.

How five masterful makers integrate CNC and CAD technology into their woodworking.

by Tim Celeski

pages 51-57

Woodworking requires a broad set of skills and strategies, and for most, it’s only after mastering the bedrock tools and gaining years of experience that we consider adding digital tools and skills to our workshops.

Yet computer numeric control (CNC) machinery has been around for decades – cabinetmakers began adopting the technology early on, perhaps because the benefits of efficiently cutting plywood parts are obvious.

But furniture makers, instrument makers and other small-scale specialists who create out of solid wood are now adding or considering CNCs and the computer-aided design (CAD) that directs it. Creative professionals in particular are constantly pushing the limits of their tools and their own creativity. New tools – including digital technology – sometimes open up new possibilities.

With machines sized for smaller spaces, and falling prices, part-time and home woodworkers can now reasonably consider CNC technology – so it’s a perfect time to peek in and see what a handful of woodworkers who have already made that jump are up to. Here’s a look at what five woodworkers are doing with CAD software and their CNCs. The group consists of four furniture makers – Bob Spangler, Curtis Erpelding, Darrell Peart and me, Tim Celeski – and one guitar maker, David Myka.

Websites: Visit the websites of the makers featured here to see more of their work.

Curtis Erpelding

Darrell Peart

David Myka

Bob Spangler

Tim Celeski

Article: Get an introduction to CNC and CAD technology and terms in “Digital Woodworking.”

blog: Read the author’s posts on digital woodworking on the PWM Shop Blog.

From the December 2017 issue, #236

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.