We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

French Polish: Six Easy Steps to a Beautiful Finish

by Alan Lacer

This article originally appeared in the November 2006 issue of American Woodworker Magazine #125.

French polish adds extraordinary depth to gorgeous wood. This finish is perfect for bowls, vessels, lamps and other turnings that aren’t handled often or are exposed to moisture, alcohol or heat. It’s easy to apply: Just hold a cloth moistened with the finish directly to your project as it spins on the lathe.

What is French polish? It’s simply shellac and a little oil applied with a pad. The oil acts as a lubricant when you apply the finish. French polish is available as commercially made products, also labeled as padding lacquer or friction polish, but I prefer to make my own from flakes, which guarantees freshness. You can achieve a variety of effects because shellac is available in a range of colors (see “Buying Shellac,” below). Here’s how you can mix your own French polish, choose different colors, apply it and rub it out.

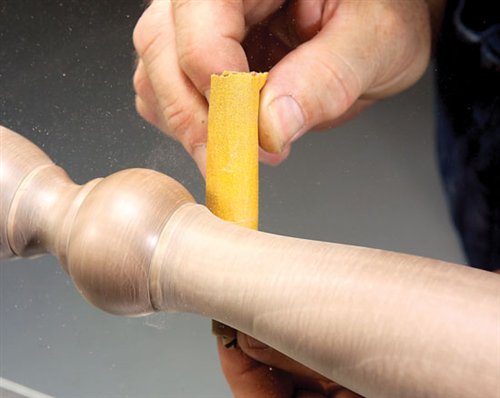

Step 1: Sand with Fine Grits

Thoroughly sand all surfaces of your project to eliminate torn grain, spirals and ridges. Start with 120-grit and progress through 150-, 180- and 220-grit sandpaper. If sanding scratches still show, continue with 320- or 400-grit sandpaper. Maple and cherry often require these finer grits. After sanding, remove the dust using an alcohol-moistened paper towel.

Sand your piece to eliminate flaws and sanding rings. Remove sanding dust using a paper towel moistened with denatured alcohol held against the workpiece while it’s spinning.

Step 2: Mix the French Polish

You can use shellac flakes or premixed liquid shellac to make French polish. Either way, your goal is to make a 1-1/2-lb. cut, which is the equivalent of mixing 1-1/2 lbs. of flakes with 1 gal. of denatured alcohol. That’s far too much finish for most projects, however. If you use flakes, dissolve 1-1/2 oz. of flakes with 1 cup of denatured alcohol. Premixed liquid shellac comes in a 3-lb. cut. To make approximately a 1-1/2 lb. cut, thin it with an equal amount of denatured alcohol.

The final ingredient of French polish is an oil, which acts a lubricant to prevent your applicator cloth from dragging or sticking. Add 1 tablespoon of mineral oil for every 3 liquid oz. of 1-1/2-lb.-cut shellac.

French polish is a mixture of shellac and oil. Little oil is needed; it acts as a lubricant for the shellac.

Step 3: Apply

Adjust your lathe to run at a moderate speed, about 500 to 800 rpm, slower for large-diameter turnings. Make an applicator for applying the French polish from a densely woven, soft, white cotton cloth that has been washed many times to remove all lint. Soften the pad with alcohol before dipping it into the French polish.

Shake the French polish to suspend the oil, as though it were an oil-and-vinegar salad dressing. Turn on the lathe, saturate the cloth pad and flow on the finish. If the cloth grabs, add a half teaspoon of oil. Let this coat dry for 30 minutes before you sand it. The surface will feel dry right away, but don’t grow impatient. If you hurry, the next coat will dissolve the first and you’ll get nowhere in a hurry.

Liberally apply French polish from a moistened cloth to the spinning workpiece. Wait at least 30 minutes between coats.

Sand between coats using a fine synthetic sanding pad. Five or six coats produce a beautiful, deep finish. Amber shellac adds a warm tone to this walnut leg.

Your cloth will stiffen between coats. Soften the cloth by moistening it with denatured alcohol and then dip in the French polish.

Step 4: Buff the Finish

After the last coat, you can leave the polish as is for a high luster. If you prefer to soften the luster, let it dry several days and rub it out with a finishing compound or fine abrasives. I like to use automotive polishing compound for this process because it costs little, is readily available and does a great job. Apply the compound with a soft cloth. Work gently until you get the look you’re after. If the compound gets trapped in the pores, wash it off with naphtha or mineral spirits. Neither will harm the finish.

French polish is naturally glossy. Rub out the finish with automotive polishing compound or fine abrasives if you want a soft luster instead.

How to Buy Shellac

Shellac comes in a number of different colors, making it a versatile finish. You can use lighter shades of shellac to preserve natural color or use dark shades to add a warm color. I prefer to use lighter shades on light-colored woods and darker shades on dark woods.

Shellac isn’t darkened by adding pigment. Shellac is made from a resin that’s naturally dark; bleaching the resin produces different grades of clearer finishes. Shellac is available in dried-flake form in a range of reddish brown, orange, yellow and pale blond colors (see Sources, below). Flakes have an extremely long shelf life. You can make any quantity of shellac by mixing the flakes with denatured alcohol.

Shellac is also available at hardware stores in premixed form. Its shelf life is one to three years. Be sure to check the freshness date on the can, because aged shellac won’t harden properly. Premixed shellac is only available in clear or amber colors.

Sources

Shellac.Net, www.shellac.net Shellac flakes, $11 tp $17 per pound.

Klingspor, (800) 228-0000, www.woodworkingshop.com Synthetic steel wool, 10 pack, #NW06254, $9.

Wooden Post, (888) 595-7126, www.woodenpost.com

Abralon synthetic sanding pads, 500 grit, #1778, $5.45 ea; 1,000 grit, #1779, $5.45 ea.

Source information may have changed since the original publication date.

This article originally appeared in the November 2006 issue of American Woodworker Magazine #125.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.