We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

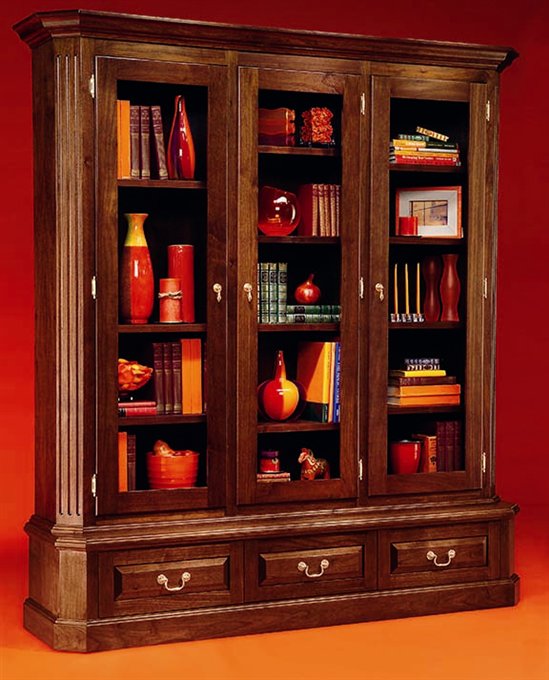

Grand Walnut Bookcase

Rich Walnut, elegant details and secret storage in a design that’s fast and straight forward to build

By Randy Johnson

| Sometimes a new piece of furniture conjures up images from a distant time and place. This bookcase, I imagine, would fit right into an early 20th-century lawyer’s office, filled with leather-bound volumes and smelling of cigars. Rich walnut and generous moldings give it a luxurious feel, and hidden compartments are perfect for top-secret documents. The glass doors are as practical today for keeping dust off your books as they were 100 years ago. I’ve designed this bookcase for a thoroughly modern cabinetmaker, however. Its plywood cases are built with biscuits, the drawers use full-extension ball-bearing slides and the lipped doors are hung with easy-to-install wrap-around hinges. To make this large project more manageable, I built it in sections: a drawer unit below, three separate bookcase units above and a crown molding unit on top. The modular design also makes it easy to move it around your shop and into your house. A big project like this does require a bit of experience. You’ll |

You may also like… |

| The modular design of this cabinet makes it easy to build and move. | Click any image to view a larger version. |

| Secret storage below the drawers provides a hiding place for valuables. |  |

| Lipped doors are easy to fit and hang and will even hide gaps caused by the doors being slightly warped or out of square. |  |

| Both the lower drawer unit and the upper bookcase units have hollow ends. They act as torsion boxes, strengthening the units. |  |

| Gluing the angled corners can be tricky, but it’s easy with a pair of plywood cauls. They hook around the front stile to prevent slipping and apply pressure to the corner’s face. |  |

| Trim the base top of the drawer unit even with the case. A perfect fit is important, and it’s much easier to achieve with a flush-trim router bit than by measuring and sawing. |  |

| Join the three bookcases with coupler bolts. Use a clamp to hold the cases together and double-check that the face-frame rails and stile line up flush at the top and bottom of the cases. |  |

| Cut the crown molding. Nesting the molding against the table and a tall auxiliary fence simplifies mitering, because it doesn’t require a compound miter setup.

|

|

| Attach the crown molding to the mounting board with a brad nailer. Use a spacer to create a lip on the bottom side. This lip will overhang the top edge of the bookcase units and hide the joint. |  |

| Add triangular glue blocks behind the crown molding for added strength. This crown assembly is screwed to the top of the bookcase.

This story originally appeared in American Woodworker November 2005, issue #118. |

|

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.