Hardware doesn’t have to come from a catalog.

You can make your own. The raw materials are

inexpensive and you won’t have to buy lots of

special metalsmithing tools, because most

of the things you’ll need are already in

your shop. Learning the techniques for

working copper can be rewarding and

fun. Annealing and work hardening

were new to me, and may be to

you, but cutting, hammering,

and drilling are familiar to

woodworkers.

Working copper is a blast!

I was pleased with the very first copper piece I made, and my

results kept getting better the more I practiced. Once you’re

familiar with the techniques, you’ll be able to make all the

hardware for the AW Stickley-Style Sideboard project (available

from awbookstore.com)—or just about any Mission or Arts and

Crafts style piece of furniture in a couple of weekends. If you

decide to try making your own, I guarantee that you will enjoy

the process and be thrilled by the results.

Materials and sources

For the AW Stickley-Style Sideboard, you’ll need 2 sq. ft. of 48-oz.

copper sheet stock (.064 gauge) for hinge straps and backplates,

3′ of 5/16″ copper rod stock (AISI grade #110) for bails, 10″ of

1/2″ x 1/2″ copper bar stock for posts, and 10″ of 4-gauge copper

grounding rod for post pins (Photo 19). Sheet metal and architectural

metal fabricators are often willing to sell the small amounts

of sheet stock you’ll need. Rod and bar stock is harder to find.

Try salvage yards or order through the mail (see Sources).

Grounding rod is available anywhere electrical wiring supplies are

sold. You’ll also need pickling flux and silver solder, and perhaps

a patinizing solution (see “The Look of Aged Copper”). All of

these things are also available through the mail (see Sources).

Tools

The only specialized tools you’ll need to work the copper are

hammers and a punch, something to pound on, a heat source,

and places to heat and cool the metal.

You can buy real metalsmithing hammers (see Sources),

or use some elbow grease and make your own from inexpensive

16-oz. ball peen hammers. Be sure to wear eye protection when

you try this.

Reshape one flat hammer face into a shallow dome (Fig. A,

Planishing Hammer) using a disc or belt sander. The shape of the

dome determines the size of the mark. I found a 5/16″ dia. mark

the most attractive. Some areas that need texture are too small for

the planishing hammer, so I domed the tip of a length of steel rod

(Fig. A, Mini-planisher). Shape the face of the second hammer

into a shallow-domed rectangle that slopes toward the handle

(Fig. A, Forming Hammer). To quickly get the rectangular shape

on this one, I cut away the unnecessary steel with a 4-1/2″ cut-off

wheel in my grinder/sander before moving to the disc sander for

final shaping. You can do this whole job on the disc sander, but

it will take longer. A third hammer face remains flat. Smooth and

polish all of these faces with an orbital sander, working through

sandpaper grits up to 600. Any blemishes left on the hammer faces

will be transferred to the copper.

To achieve a crisp texture on the copper you must hammer

it on a hard surface. Wood is not hard enough. I used a piece of

1/2″ steel plate for the hinge straps and backplates (Photo 2) and

a massive steel block for the bails (Photo 13). I bought both at a

salvage yard for next to nothing. Raising the crowned shape of the

hinge straps and bolt heads can be done using a piece of maple

1-3/4″ x 4″ x 12″ (Photo 5) as a forming block.

You’ll need a high-output, self-starting torch and a tank

of MAPP gas to get the copper hot enough to anneal it—

propane won’t do. I made my own annealing tray by filling

an aluminum cake pan with pumice stones (see Sources,

p. 8) and used a plastic container for the quenching bath. |

|

Click any image to view a larger version

1. Saw the hardware pieces following paper patterns

fixed to the copper sheet with spray adhesive. Copper

is soft enough to cut on a bandsaw using a generalpurpose,

fine-tooth blade. Centerpunch all drill hole

marks on the patterns, smooth all burrs and refine

the edges with abrasives or files. Remove paper and

adhesive residue, then polish the copper faces with

400-grit wet/dry sandpaper.

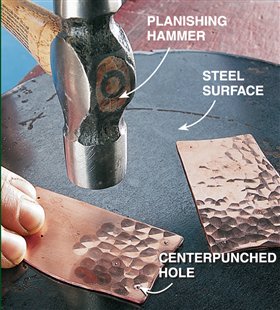

2. Create a hammered

texture by striking the

copper with a planishing

hammer on a flat steel

surface. Be sure to

hammer the face—the side

with the centerpunched

holes. Practice hammering

on scraps so you can get

a feel for the metal and

develop a hammering

rhythm. Slightly overlapping

each stroke creates a

nicely balanced look.

6. Pound an annealed strap

into the forming block to create

the raised center. Use the forming

hammer. The strap will bend

dramatically as it is worked, but

you can flatten it by gently tapping

its top side with a non-marring

mallet. Anneal the copper when it

becomes work hardened (see “The

Annealing Process”).

8. Hammer texture marks

onto the convex profile at the

tip of the freshly annealed hinge

strap. A ball peen hammer held

in a vice serves as a stake—an

anvil for texturing a curved object.

Make sure each blow of the

planishing hammer is centered

on the stake hammer below. As

you work, move the hinge strap,

not the hammer, for each blow.

Use the forming block to flatten

the tip if it distorts.

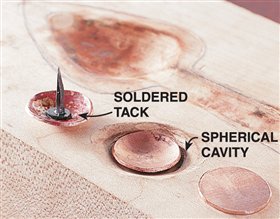

11. Hammer penny-sized polished

copper discs into a spherical cavity

in the forming block with the ball peen

hammer. Center a steel tack in the

concave backside and silver-solder it

in place.

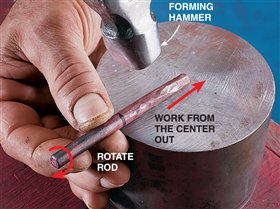

13. Pound around the annealed rod with the forming

hammer to lengthen and taper it. Work from the center

out, and rotate the rod with each blow. It will take four

to five courses of pounding and annealing to achieve the

final length and the desired taper.

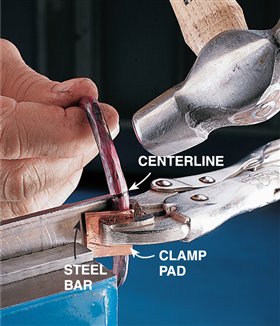

16. Start the bend of the door’s

V-shaped bail by pounding it, freshly

annealed, over a 1″ x 1/4″ steel bar

clamped so its edge is slightly below the

bail’s centerline. Anneal the bail when

you sense work hardening. Frequent

annealing assures that bends occur

where you want them. Repeat the

process of annealing and bending until

the final V-shape is attained. Make sure

the pins align.

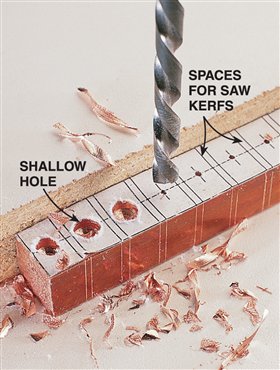

18. Drill holes in copper bar stock that

has been divided into 1/4″ sections,

leaving room for saw kerfs between them

(Fig. B, posts). These shallow holes,

which are centered in each section, will

have pins soldered into them. After

drilling, carefully saw between each post

from the pin end, stopping two-thirds

of the way through. This establishes

the individual posts, but keeps them

connected and easy to handle.

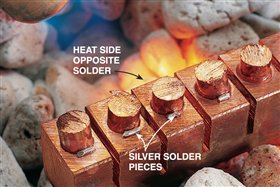

20. Solder the pins

in place. First coat

all pieces with flux

and hammer the

pins in place. Place

a sliver of solder at

the junction of each

pin and post. Then

heat the bar, holding

the torch on the side

opposite the solder,

until the solder flows

into the joints. Heat

the metal, not the

copper, and don’t

overheat. After soldering, sand the pins so they’re slightly longer than the thickness

of the backplates. Then drill shallow 5/32″ dia. holes in the end of each one

to facilitate riveting (Photo 22 and Fig. D).

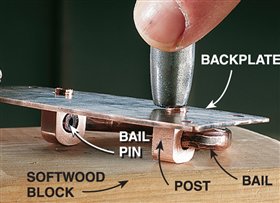

23. Rivet posts to

the backplate. First

position posts on

the pins at the ends

of a bail. If the bail

pins are properly

bent, the posts will

align parallel to one

another. Make necessary

adjustments

before positioning

them on the backplate. Work on a softwood block so the

bail holes in the posts are not distorted. If you don’t have

three hands, get help from a friend. |