We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Mission Blanket Chest

If you love

Mission-style

furniture, here’s

the perfect

complement to

your bedroom.

By Tom Caspar

|

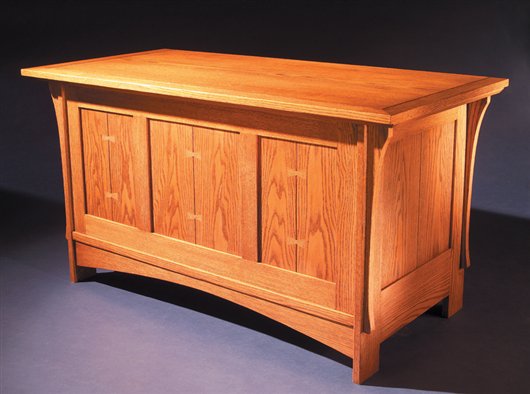

Store blankets, bedding and memories inside this huge chest. Three frames and a plywood back make up its basic structure, and all the other parts are added on, one by one, so building it is about as easy as making frame-and panel doors with a router table. One do-it-all router bit cuts virtually every joint and another basic bit adds a design element that saves a ton of work. This story also contains an entire section devoted to showing how to make and install the distinctive butterfly inlay.

|

|

You may also like…

Shaker Blanket Chest

Frame and Panel Hope Chest

Pennsylvania Blanket Chest

|

|

Select the best

figure for the panels,

legs and rails before you

cut up your wood. Cut a

window out of a piece of

cardboard that’s the size

of one of the two boards

that make up a full panel.

Arched figure looks

great in panels, as long as

the arches are centered.

Straight figure works

best for legs and rails.

|

|

Click any image to view a larger version.

|

|

Assemble the

frames without glue.

Double-check the width

of the opening before

cutting your panels to

size. The panels float in

the grooves and are cut

undersize so they can

expand and contract side

to side.

|

|

|

|

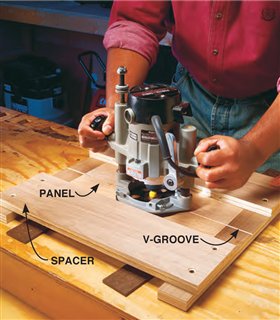

Rout a v-shaped

groove down the

glue joint in the middle

of each of the panels.

Build a simple jig to

ensure the V-groove is

perfectly straight and

centered on the glue

line. Support the panel

with 1/4-in. spacers.

|

|

|

Glue the butterflies

Cut the corners of the recess with a chisel or

knife. They’ll be rounded after routing, but they

must be cut to acute angles so the inlay fits.

Spread a thin layer of glue in the recess, put in

the inlay, scrape off any glue squeeze-out, and

cover the inlay with a small piece of white

paper. Clamp a thick board over the inlay and

let the glue dry. The paper will absorb any

further glue squeeze-out. After the glue dries,

remove stuck pieces of paper by lightly wetting

them. Level the inlay with a block plane or by

scraping and sanding.

|

|

|

|

Stain all the panels

before gluing the case

together. If you stain the

panels after the whole

case is assembled, you

can’t get stain all the

way to the outer edges.

These edges will show

as unsightly bare wood

when the panel shrinks

in dry weather.

|

|

|

|

Glue the case

together. Use flat

2x4s to spread out the

pressure of the clamps.

While you’re tightening

the clamps, make sure

the case is square with

a carpenter’s framing

square. You can also

measure from corner

to corner and adjust the

clamps until the diagonals

are within 1/16 in.

of each other.

|

|

|

|

Add the ledge

frame to the case.

The ledge covers all the

grooves, splines and any

uneven joints along the

top of the case.

|

|

|

|

Attach the hinge to

the top and case. A long

continuous hinge is easy

to align and install. We

liked this particular hinge

because it wraps over

the plywood back, allowing

you to run screws

into the back’s face and

edge for extra strength.

|

|

|

|

Stain the entire

case. Raise the case

off your worktable with

blocks of wood that have

screws driven through

them. Now you can apply

stain all the way around

the bottom of the legs

without smearing.

|

|

|

Product Recommendations

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.