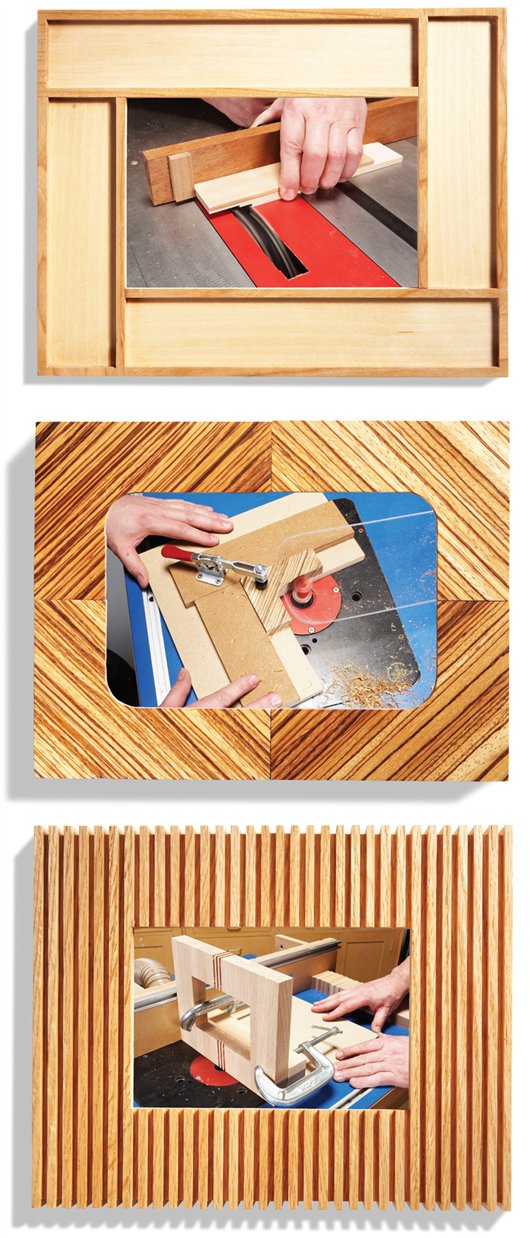

Magnetic Frame

Snaps

together

and pulls

apart,

so changing

photos is

easy.

This frame consists of four

identical corner sections

that assemble around the glass,

photo and back board (Fig. D).

Rare earth magnets hold the sections

together. To make this

frame, you’ll need a routing jig

(Fig. E), a pattern and two pieces

of 3/4-in. (or thicker) stock cut to

4-1/16-in. by 4-9/16-in. rectangles.

Build the routing jig first. It’s

used to rout the inside edge of

each piece as well as the grooves

that house the photo assembly.

Use the jig to make the pattern.

Saw a 3-1/16-in. by 4-1/16-in.

piece of 1/2-in. MDF into an Lshape.

Install it in the jig and

rout the inside edges with a 1-

in.-dia. pattern bit (a flush-trim

bit with the bearing mounted

above the cutting flutes).

Use the pattern to lay out the

frame pieces on the two blanks

(Photo 1). Cut the short legs to

length (Photo 2). Then cut the blanks

apart on the bandsaw, install them in

the jig and rout the inside edges

(Photos 3 and 4). Install a 3/16-in.-

wide slot cutter and rout a

1/2-in. deep slot for the photo

assembly (glass, photo and

back board) in each piece

(Photo 5). The photo assembly

provides the frame’s structure,

so it must fit the slot

snugly, but without binding.

Size the slot’s width to fit the

thickness of your photo assembly

(for single-strength glass

and a 1/8-in. back board, the

slot will be slightly less than

1/4-in.-wide).

Fill the slots to fit the photo

assembly (Photo 6). Before

you glue in the strips, assemble

the frame around the

assembly to test the fit. After

gluing, flush each strip with

the end. Then drill centered

holes for the rare-earth magnets

(Photo 7) and install

them flush with the ends—make sure

to orient the magnets’ poles correctly!

Secure the magnets with epoxy.

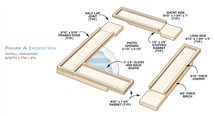

Fig. D: Exploded View

Fig. E: Jig for Routing Inside Edges

|

|

1. Lay out two corner sections on each

blank. Make sure the grain runs

across the outside corner. If it runs

toward the corner, as on the blank in

the background, the pieces will be

impossible to rout.

2.Cut the short legs to final length

using the miter gauge with a fence

and a stop.

Caution: The blade guard must be

removed for this operation. Be careful!

3. Rout the inside edges with a 1-in.-dia.

pattern bit. Because of the grain’s

direction, you can only rout one leg at

a time. Stop before the bit touches the

adjacent leg or disastrous tearout will

occur.

4. Flip the workpiece over to rout the

other leg. Routing into the corner

can still cause tearout, so complete the

job in stages. Rout a bit, flip the workpiece

and rout a bit more. Then repeat

the process.

5. Rout a centered slot in each piece.

Center the bit by eye. Then make

two passes, one on each face. Rout

halfway, as before, then flip the workpiece.

Once the slot is established, you

can rout against the grain to widen it.

6. Reduce the slots’ depth to 3/16-in.

by gluing in fill strips. Leave the

inside corner 1/2-in. deep, to accommodate

the square corners of the glass.

7. Drill holes for the rare earth magnets

using a fence and a stop block.

The fence centers the hole between the

faces; the stop block centers it

between the edges. |