We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Self-locking design requires no glue

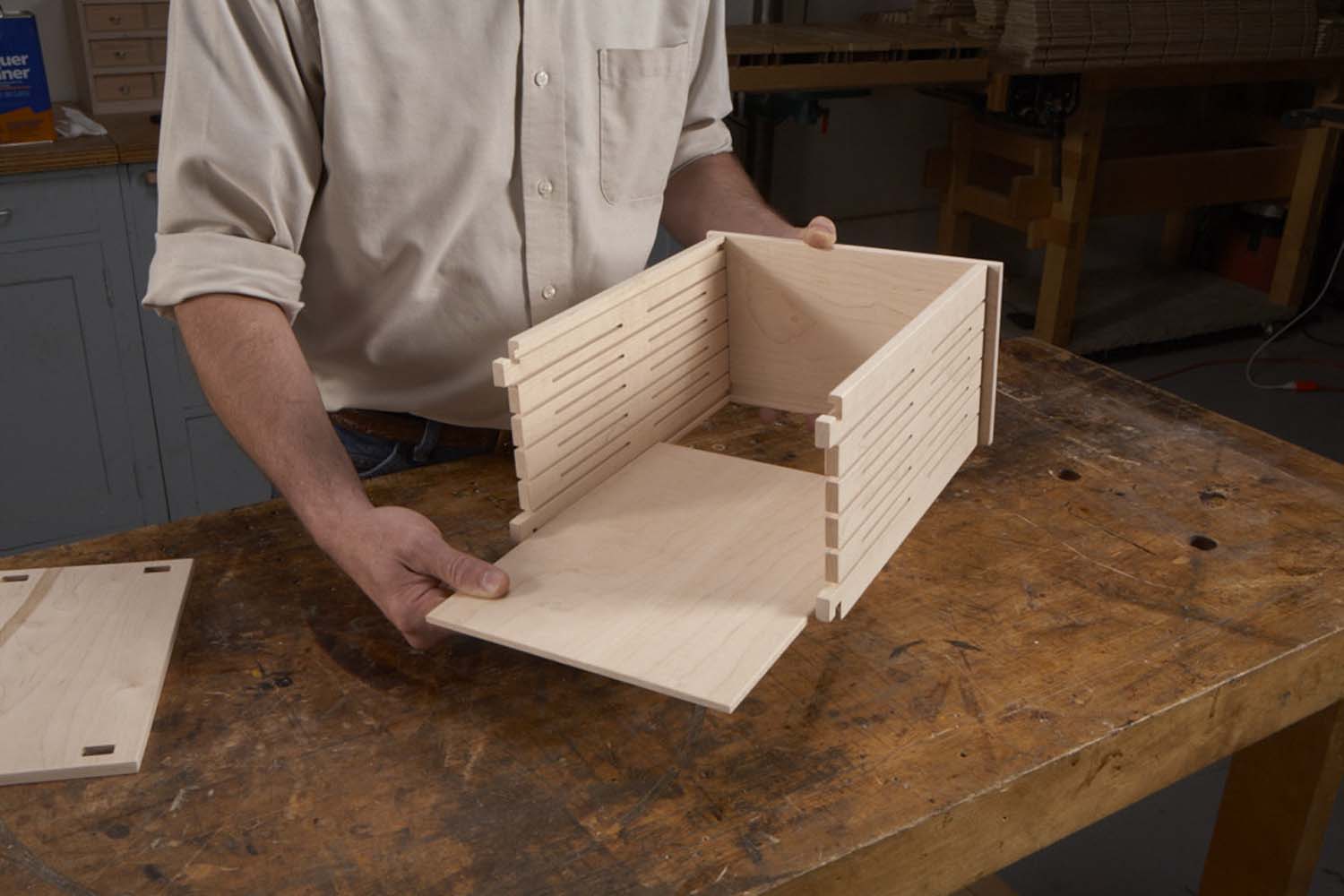

SQUEEZE AND SNAP! That’s all it takes to assemble this CNC-routed box. The joint’s flexibility comes from a series of slots that allow the hooked tenons to be compressed, so they slide into the mortises. When released, the tenons spring back into position, locking the parts together. While not as rigid as a glued joint, the assembled spring joints are surprisingly stiff. And you can enjoy assembling and disassembling the box as often as you like.

The key to making this joint fit well—neither too tight nor too loose—depends on several things. The primary factors are the spacing, length and number of the slots as well as the tolerances between the tenons and mortises. The spring-jointed front and back are also 1/8” taller than the mortised ends. This small difference in height keeps the hooked tenons slightly compressed after assembly, which adds additional stiffness to the joint. The type of wood and the thickness of the parts also affect the joint’s flexibility.

Accommodating all these variables can be a bit of a challenge and I made eight prototypes before I found a fit that I liked. But similar to mastering hand-cut dovetails or mortise and tenon joints, the time spent working out a solution for this box was a very satisfying learning experience.

The slots become part of the box’s design and variations are almost unlimited. However, I kept the shape and arrangement of the slots for this box simple in order to show how the parts are made. See photos below for how to build this box!

Wedge the parts in place: Holding parts secure is important for all CNC work. For this project I used 3/8” deep pockets—the same thickness as the parts—cut into 3/4” MDF. I then added 1/2” thick MDF wedges to secure the parts. The wedges are very easy to install and remove with a couple mallet taps. Plans and tips for building this type of jig are available at AmericanWoodworker.com/CNC.

Rout the front and back parts: First cut around the tenons, then the grooves, next the two outer end slots, then the three inner end slots and finally the center slots. This cutting order is important because it keeps the router bit from chattering as the part becomes increasingly flexible. It’s also important to use a (1/8”) down-spiral bit, which pushes the part down during routing.

Test-fit the parts: Rout the mortises and check the fit of the tenons. The parts should fit together snugly, but without binding. I found cutting the mortises .015” larger than the tenons provided a good, slightly tight fit. Once the faces of the parts were finish-sanded and the corners were eased, the fit was perfect.

Rout the latch parts: The lid’s two part latch is cut from one piece of wood but connected with a thin tempoary tab between the parts. These parts are somewhat delicate to machine, so the down-spiral bit really proves its worth. An up-spiral bit can lift the parts and chew them up—I speak from experience!

Test fit the latches: Rout grooves on the underside of the lid for the latch parts and test their fit. The groove for the fixed side of the latch runs the full length of the latch. The groove on the spring side of the latch is shorter, since the ends of the spring latch must be free to flex. The latch parts are glued into the slots after all the parts are sanded.

Assemble the first three parts: Two dimensions are key to making this joint work. First, the five 1/8” wide end slots allow the tenons to be compressed up to 5/8”.

Second, the through mortises in the ends are spaced so that the hooked tenons have to be compressed only 1/2” to pass through. This 1/8” leeway eases the assembly. Anything less than 1/8” makes it difficult or impossible to assemble.

Insert the bottom panel: The 1/4” thick bottom panel fits into grooves in the front and back parts. These parts also have grooves near their top edges, which serve as clips for the two latch parts. These grooves are all the same size, so the front and back parts don’t have a top or bottom. The ends have a single groove for the bottom panel.

Snap on the last part: Slip the remaining end over the hooked tenons, working both sides of the mortised end down equally. Pressing one side down first will only rack the end and cause it to bind. If the parts have been correctly cut, this last end should snap into place with a satisfying pop.

Working the Spring Latch

Opening the box is a bit of a puzzler, because the spring-latch system is completely hidden when the lid is closed. Here’s how the system works: Tabs at the ends of the spring latch flex about 1/4″ (above). These tabs fit about 3/16″ into the latch groove in the back of the box. When the lid is pressed from the front (below), the spring latch flexes deeper into the groove at the back, allowing the fixed latch to slip inside the box. Releasing the lid relaxes the spring latch, which in turn engages the fixed latch in the groove in the front of the box. The lid is now locked in place, because both latches are clipped into the latch grooves. To open the box, simply press on the front of the lid and lift.

Opening the box is a bit of a puzzler, because the spring-latch system is completely hidden when the lid is closed. Here’s how the system works: Tabs at the ends of the spring latch flex about 1/4″ (above). These tabs fit about 3/16″ into the latch groove in the back of the box. When the lid is pressed from the front (below), the spring latch flexes deeper into the groove at the back, allowing the fixed latch to slip inside the box. Releasing the lid relaxes the spring latch, which in turn engages the fixed latch in the groove in the front of the box. The lid is now locked in place, because both latches are clipped into the latch grooves. To open the box, simply press on the front of the lid and lift.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.