|

This table is an accurate reproduction

of one purchased by

Molly Brown and her husband

in the late 1880s, when they were starting

their family in the rough mining

town of Leadville, Colorado. It easily

disassembles for transport so it could

lend instant civility to a new home in

unfamiliar surroundings. Simply but

ingeniously built, it bears all the hope

and exuberance of a young America during

its age of westward expansion.

Apparently the Browns liked this

table. They kept it with them even after

they struck it rich, and moved from

Leadville to a large house in Denver’s

most prestigious neighborhood. It still

resides there, in what is now the Molly

Brown House Museum.

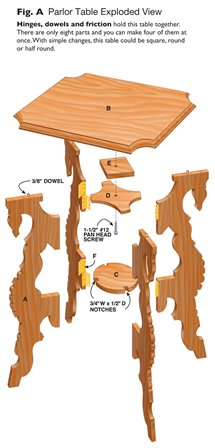

Rigid and durable, this table is built

with the simplest joinery. You’ll only

need about 15 bd. ft. of 3⁄4" thick walnut,

and you can build it in a weekend

using your tablesaw, bandsaw, router and

drill.

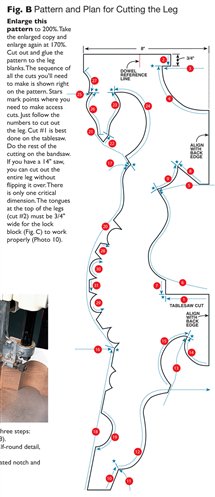

Making the legs

Look for boards without sapwood that are

8-1/2" wide, otherwise you’ll have to glue pieces

together. You can saw the legs individually, but it’s

better to saw all of them at once. Stack the four leg

blanks together, using pieces of double-stick tape

(Photo 1). Keep the edges aligned. Then affix a

full-size paper pattern on one side (Photo 2) and

saw out the legs (Fig. B and Photo 3).

Sawing the ganged-together leg blank on the

bandsaw is a simple combination of curved cuts,

access cuts and relief cuts. To be successful, it’s

important that your saw is in tune and the blade is

sharp. A 3/16" 4-tpi skip-tooth blade (see Sources, below) will do a good job. To make accurate cuts

with smooth curves, it’s also important for you to

be in tune with the saw. Use a light touch so you

can find the blade’s optimal feed rate and see how

it tracks. Then advance the workpiece steadily—

don’t try to cut too fast—and let the saw do the

work. Make access cuts first. They allow the blade

to escape from dead-end curved cuts easily.

After sawing, clamp the legs in a vise and sand

the edges (Photo 4). Attach the hinges (Photo 5),

then pry the legs apart. Use a putty knife with

blunted edges and smooth faces—any burrs on the

knife will scratch the wood. After the legs are loose,

remove the paper pattern and any double-stick

tape that remains. Then sand the faces.

Sanding end grain

Okay. Everybody looks for a way to avoid

sanding end grain by hand, and I did too.

After all, power tool manufacturers are happy

to offer alternatives. But I was disappointed

by all of the other approaches I tried. Progress

with profile sanders was slow and the

vibration made my hands tingle. Drum and

spindle sanders worked fine for the wider

curves, but they couldn’t get into any of the

corners. And on these legs there are more

corners than curves. Besides, sanding the

wide curves is just as easy to do by hand. I

even tried cutting the legs on a scrollsaw, one

at a time. Scrollsaw blades cut very cleanly,

but progress through 3/4" thick walnut was

slow. And without a lot of practice, it’s hard

to cut smooth sweeping curves with those

tiny blades, which means you’re going to

have to sand the profiles anyway.

Sanding end grain by hand can be surprisingly

efficient if you have the right tools and

use the right sandpaper. 3M 216U sandpaper

(it’s gold) is worth its cost because it cuts fast

and lasts. Start with 100 grit. You’ll be

amazed how quickly this stuff removes saw

marks and smoothes end grain. Work your

way through 120 and 180 grits, then use 280

to finish. There’s no need to sand with the

grain—the scratches are too small to see.

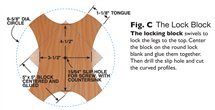

Attach the legs to the top

First, make the top, a rectangle with radiused

corners (Photo 6). Rout the top edge

with a 3⁄8" beading bit. Using a doweling

jig, drill dowel holes in the legs, transfer

their location to the top (Photos 7 and 8),

and drill these holes. Then glue dowels

into the legs. Make the lock block (Fig. C

and Photo 9) and install it. Then fit the

legs to the top, and test the locking

operation.

A notched shelf

stiffens the legs

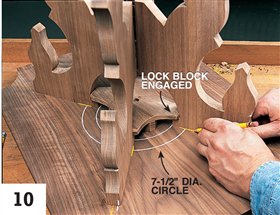

Use the top as a template to make the

notched shelf (Photo 10). For the notches

to slip around the legs without being too

loose, saw on the insides of the lines

you’ve drawn on the shelf. Test the fit on

the assembled table. If the fit is too tight,

widen the notches slightly with sandpaper

or a file. If it’s too loose, just make another

shelf. (That’s what I had to do!)

A canned finish

This project begs for a spray finish. Brushing

the legs would be a drippy nightmare

and oil would make the end grain too

dark. I used shellac, sprayed from an

aerosol can as a seal coat. First I folded the

legs together and sprayed all the end grain

edges at once. Then I opened them up

and sprayed the faces. It took only 10

minutes. The next day, after a light sanding,

I sprayed on a topcoat of aerosol

polyurethane.

The Unsinkable Molly Brown

Young Margaret Tobin traveled west to

Leadville, Colorado in 1886 to seek her

fortune. Within a year she met and married

J.J. Brown (13 years her senior), an

engineer for the Ibex Mining Company.

In 1893, thanks to a process J.J. devised,

a played-out silver mine, called the Little

Johnny, was found to have one of the

largest veins of gold and copper ore in

the country. The Browns became millionaires

overnight.

In 1894 they moved to Denver, where

Molly immersed herself in Denver

society.

In 1912, she gained national recognition

for her heroism the night of the

Titanic disaster. Mrs. Brown found herself,

with other horrified survivors, adrift

on a lifeboat. Taking command from the

panicked sailor in charge, she began

rowing and instructed others to do the

same, safely piloting the boat through

the icy darkness. Later she raised

$10,000 for families of victims.

She was an excellent fund-raiser for

charitable causes in Denver, where she

was a champion for miners and orphans.

Fiercely independent and outspoken,

she ran for the Senate before women had

the right to vote. She was named to the

French Legion of Honor for her work

entertaining soldiers in WW I.

Not even the largest ocean liner disaster

the world had ever known could stop

the Unsinkable Molly Brown!

Sources

(Note: Product availability and costs are subject to change since original publication date.)

3M, 3m.com, 800-362-3550, Scotch 666

double-stick (coated) tape, 3/4".

Woodcraft, woodcraft.com,

800-225-1153, 3/16" 4 tpi bandsaw blade.

Home center, Brass butt hinges, satin finish,

1-1/2" x 2"; Dowel centers.

Klingspor’s Woodworking Shop,

woodworkingshop.com, 800-228-0000,

Flexible sanding pads (complete set of 18

profiles), #KL50000; Teardrop hand

sander, #KL05245; Flat rubber sanding

block, #KL05215.

Body supply stores, 3M 216U Production RN Fre-Cut sandpaper.

Art supply stores, Chalk marking pencils.

Cutting List

Parlor Table Exploded View

Pattern and Plan for Cutting the Leg

The Lock Block

This story originally appeared in American Woodworker April 2000, issue #79.

April 2000, issue #79

Purchase this back issue.

|

|

Click any image to view a larger version.

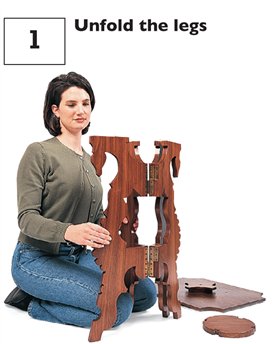

Unfold the legs.

Install the

notched shelf.

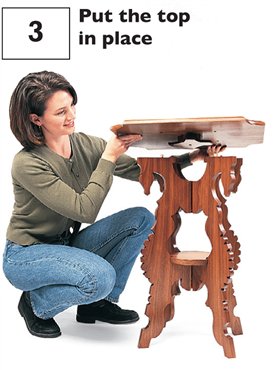

Put the top

in place.

Lock the legs and top together.

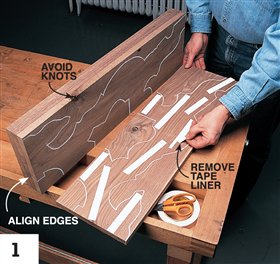

1. Hold the leg blanks together with double-stick

tape (see Sources, page 48). Using the paper pattern

at right, outline the leg on each blank. This keeps the

blanks properly oriented and shows you where to

put the tape. Press the blanks together, one pair at a

time. Keep the back edges of the blanks aligned by

standing them on a flat surface. Align the end-grain

edges with your fingers and then press the blanks

together. Glue the paper pattern on the completed

stack, aligning it with the edges (Photo 2).

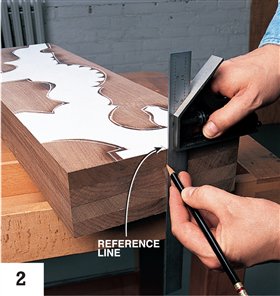

2. Transfer the line for the dowels onto all four

blanks at once, using the reference line on the paper

pattern. Before making these marks, true up the ends

of the stack on the tablesaw, using the miter gauge,

if necessary.

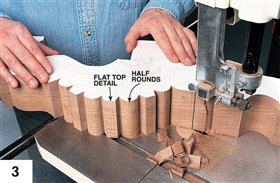

3. Saw the detail shapes at the front of the legs in three steps:

1) Saw the edges of the flat-topped details (Fig. B, #28).

2) Make a relief cut, sawing into one corner of each half-round detail,

creating a notch for the saw blade (#29).

3) Saw the half-round profile, starting at the newly created notch and

working in the opposite direction (#30).

4. You'll be amazed how quickly and accurately you can

smooth and level all four legs at once, using rubber sanding

pads and 3M 216U Production RN Fre-Cut sandpaper (see

Sources). This teardrop sander is perfect for the job because it

acts like a flexible sanding block, conforming to all sorts of

contours.

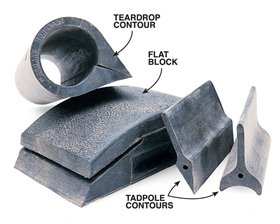

Flexible Rubber Sanding Pads

(see Sources) come in a variety of

shapes and contours, don’t cost

much and make the job of hand

sanding much easier.

5. Mount the hinges while

the legs are still fastened

together. Center the barrel

of each hinge over its joint.

Pre-drill holes for screws

with a #5 self-centering

hinge bit. Use the same

mounting pattern on both

parts of the legs.

6. Saw away the corners

of the top. Be sure to draw

diagonal reference lines for

locating the base before

you cut the corners off.

Lines drawn with colored

chalk pencils (see Sources)

show up great on dark

woods like walnut.

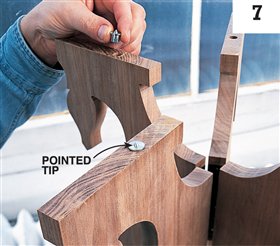

7. Insert dowel centers

(see Sources) in the holes

drilled in the tops of the

legs. Dowel centers are

designed to transfer the

location of dowel holes

from one piece to

another.

8. Position the base

on the top by centering

it on a 5-3/4" dia. circle.

Then center each leg on

its diagonal. Press or tap

the base onto the top to

set the points of the

dowel centers. Mark

both the top and one leg

for reference. Remove

the base and drill holes

in the top for the

dowels.

9. Ease the edges

of the lock block

tongues so they’ll

engage the legs

smoothly.

10. Use the top as a template for the notched shelf

that stiffens the legs. First, draw a second circle on the top

that’s the same diameter as the shelf. Then, with the table

assembled, mark where the legs intersect this circle.

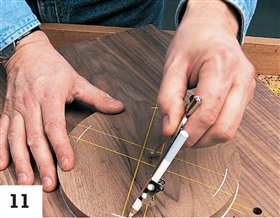

11. Locate the notches in the shelf by centering the

shelf in the circle drawn on the top and transferring

the leg lines. Then draw another 6-1/2" dia. circle

to mark the bottom of each notch.

|