We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Last week I talked about the diamond stone technique for lapping the soles of small block planes. This week I will talk about another popular method – using abrasive tapes over a flat surface.

Sometimes the condition of the plane’s sole is so bad that it requires a more aggressive approach than even the course 120 grit diamond stone can offer. In this case, I role out a 60, or 80-grit PSA sandpaper strip and affix it to a flat surface to be used as the lapping abrasive.

Choosing The Right Surface

A dedicated granite plate or the cast iron beds of a table saw or jointer is my surfaces of choice. These surfaces, once their flatness is verified by a quality straight edge, are perfect for this job. Alternatively, a heavy black 18” x 6” x 2” granite plate would be ideal for small to medium size planes, whereas the cast-iron surface of a table saw will work well for planes longer than a Jack plane.

I prefer granite over a long piece of glass for its mass and rigidity. To prevent the granite surface from shifting during lapping I place a non-slip mesh mat underneath it or set up some makeshift clamps and wooden blocks around it.

RTape Clear Choice AT60 100 Yard General Purpose Clear Low-Tack Application Tape is a great liner for your lapping surface that protects it but also makes it very easy to peel the sandpaper strips during, and after the lapping concludes.

For many years I used to affix the tape straight onto the surface but after facing the ordeal of removing it to make way for a fresh strip of paper, which involved using scrapers and mineral spirit as a glue dissolving agent, I switched to a new system that calls for a liner layer to be placed on the stone and serve as a substrate to the sandpaper.

The Surface Liner

A few years ago I found a low-tack adhesive tape that is easy to affix and later be removed from the stone without the need to resort to scrapers and solvents. My system is quite simple: I cut the liner to length, adhere it to the lapping surface, and affix the sandpaper strips over it. If I need to replace a strip of sandpaper during the lapping process (which often happens) I peel it off from the liner substrate quite easily. And at the end of the lapping process, I peel the sandpaper for the last time and leave the liner on the surface for the next use. If the liner gets damaged from the plane sole or sandpaper particles I remove it and affix a new layer of a substrate. Unlike the sandpaper tacky adhesive, the liner’s low-tack adhesive leave underneath it a non-tacky surface that is ready for future use.

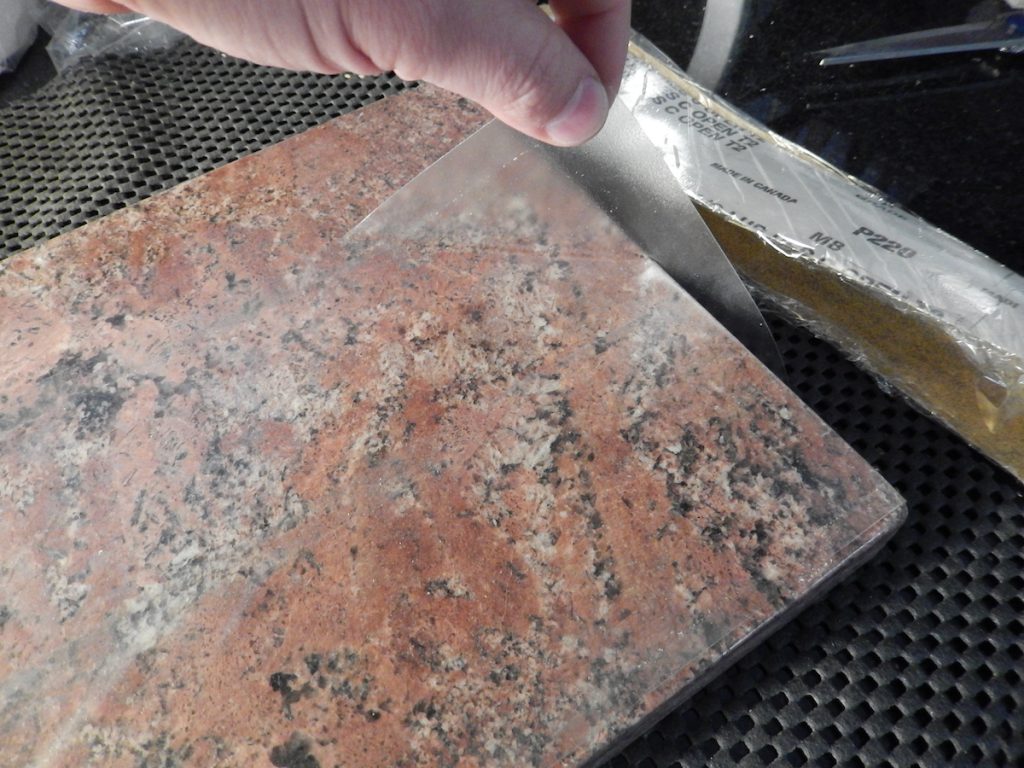

After laying out the low-tack adhesive tape onto the stone I affix a strip of sandpaper roll over it.

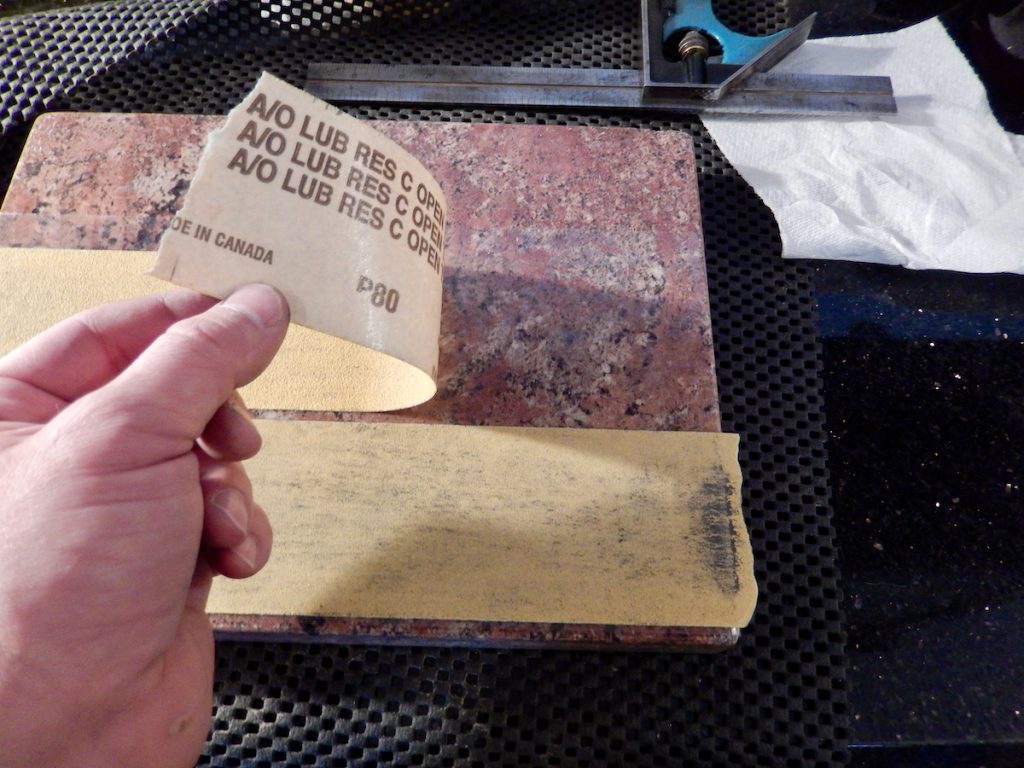

Thanks to the Low-tack tape you can remove a worn-down stip of sandpaper and replace it with a fresh one quite easily, without the need to use a scraper and solvents.

Sandpaper strips

Sandpaper strips work well but would not last forever. Their grit particles are fresh at the start but then break off with use and the sandpaper loses its bite. At that point, you’ll have to replace the strip with a fresh length of abrasive. So depending on the condition of the sole you might need to replace them a few times before your plane’s sole is truly flat.

Norton Gold and 3M™ Gold can be ordered online in many stores. StewMac, a luthier tool supplier carries it in many grit options.

Taylor Toolworks carries the high-quality 3M™ 316U Stikit™ Red abrasive rolls of sandpaper which is another excellent option.

Two or three grit sizes such as 80, 150, and 220 will allow you to progress from fast and course material removal to a smoother surface at the end of the process.

When lapping remembers to stop from time to time and vacuum the cast-iron and abrasive mineral dust that is deposited on the sandpaper.

Notice the furnished area in the middle of the sole. This area is a depression in the sole that still require lapping.

Remember to check for flattens using a straight edge and the sole sharpie serpentine line technique.

Next time I will show how to deal with lapping bigger and more challenging planes.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.