We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Q. I’ve tried to use construction-grade lumber for furniture, but the wood warped like crazy. How can I prevent that?

Q. I’ve tried to use construction-grade lumber for furniture, but the wood warped like crazy. How can I prevent that?

A. You can’t use this wood as it is. You’ve got to do some selective cutting first and then dry out the wood before making furniture with it.

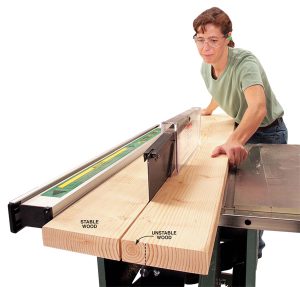

Construction-grade lumber warps for two main reasons. First, boards often contain unstable wood from the center of the tree. You can spot this by looking at the growth rings at the end of the board. If you see rings that are almost a full circle, that area of the board is likely to cup and twist.

Second, it’s too wet. The industry standard for construction-grade lumber is about 19-percent moisture content. For making furniture, the moisture content should be far less, about 7 to 9 percent. At this point,boards are unlikely to warp any further.

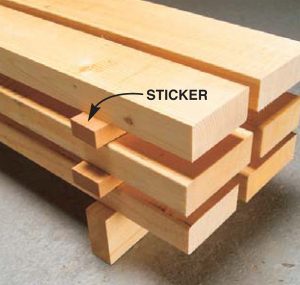

Both problems are easy to solve. First, cut out the unstable center wood by ripping your board on the tablesaw. Second, crosscut the boards on either side of large knots, which cause a board to kink as it dries. Don’t worry about small knots. Third, stack and sticker the wood indoors until it dries out.Weight your lumber with cinder blocks or sandbags to help keep it flat. Drying may take anywhere from a few weeks in a very dry environment to a few months in a more humid one.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

3. Buy kiln-dried (KD) construction lumber.

Most construction lumber is “green” which is better for nailing frames together, this is why it’s sold this way. But some lumber is sold as KD.