We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Q: What advantage does a low-angle bench plane have over a standard bench plane?

Q: What advantage does a low-angle bench plane have over a standard bench plane?

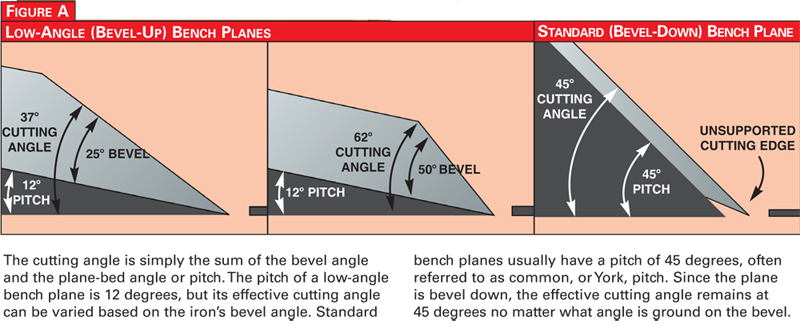

A: A Low-angle bench planes allow you to change the blade’s effective cutting angle to suit specific tasks. Because the bevel points up on a low-angle plane, the effective cutting angle varies on the iron’s bevel angle. The bevel-up configuration also means the plane blade is fully supported right up to the cutting edge. With the bevel down, the cutting edge remains unsupported along the bevel, which can lead to blade chatter (Fig. A, below).

To get the most out of your low-angle bench plane, it’s best to have a few blades on hand with various bevel angles already ground on them (Fig. A). A 25-degree bevel ground on the cutting iron makes a low cutting angle of 37 degrees that’s ideal for shaving end grain. A 35-degree bevel approximates the 45-degree cutting angle on a standard bench plane, which is best-suited for general planing tasks. A 50-degree bevel creates a high cutting angle of 62 degrees for more of a scraping cut that reduces tearout on grained wood, such as bird’s-eye maple.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

The illustration says since the since the bevel is down the effective cutting angle is 45 degrees no matter what angle is ground on the bevel. This is true but what they fail to mention is that it’s easy to grind a bevel on the back of the iron to make whatever angle greater than 45 that you wish to have. You can’t go below 45 degrees but you can go higher than 45 quite easily. Craftsmen have used that trick for a really long time. The only advantage a bevel up plane has is going below 45. Even that is only at a normal 37 degrees, a mere 8 degree difference. It’s not a big advantage. A sharp iron, proper technique, and careful setup with a bevel down plane will usually take care of any planing situation that arises.