We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Q: I’m starting off in woodworking and am confused by the number of squares available. Some look pretty sophisticated and are fairly pricey. What should I look for in a good, all-around shop square?

A: “My first choice for an essential kit of layout tools is a good square,” says John Economaki, president and CEO of Bridge City Tool Works (Portland, OR,www.bridgecitytools.com). Economaki notes that many established shops have a collection of squares, usually acquired one after the other, when the previous squares proved insufficiently accurate.

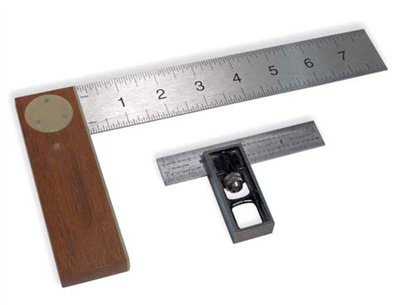

In our experience, it’s very useful to have one very precise square in your shop. You can rely on this square for machinery setup, such as setting your jointer fence and your tablesaw blade square to the table. It is possible to test your tools—and quite accurately, too—by cutting test pieces of wood, but it’s slow and cumbersome. A small, accurate square is much easier.

When choosing a square, Economaki says you should expect to spend $10 to $20 per inch of blade length for a good-quality square. Your very accurate square need not be large; between 3 and 6 in. is fine. It can be a combination model that has a 45 degree angle, or one that simply does 90 degrees. Watch out for “machinist’s squares” selling for very low prices—there’s nothing magical about the word “machinist’s,” nor are machinist’s squares necessarily more accurate. Most woodworkers also

have a larger, less precise (and less expensive) square for general use in checking their project parts. If you happen to drop it you’re not out $100.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.