We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

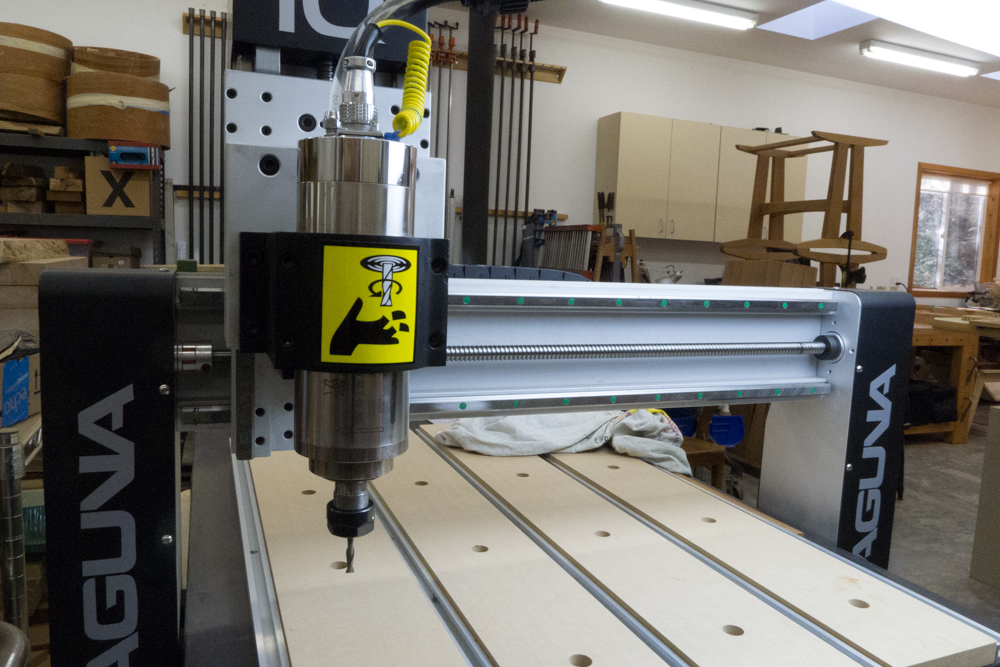

CNCs that fit This class of 2′ x 3′ and 2′ x 4′ machines is well designed for small shop woodworking tasks.

In Part One, I introduced a class of machines in this group of CNCs that fit and perform well in home and small professional shops. What they have in common is the 2’ x 3’ to 4’ size range, engineering, design, specifications and build quality. Let’s have a look at that list again.

Axiom Precision Pro Series

Laguna Tools

- Laguna IQ 24” x 36” & Laguna IQ L4F 24” x 36”

Powermatic Tools

- PM-2X4SPK 24” x 36”

Let’s Look at the Details

In the previous post, I pointed out that these machines are very similar in design, engineering, component selection, and features. Here are some of the details that make them a class unto themselves.

24’ x 36” to 24” x 48” Wide enough and long enough for many woodworking tasks. You could cut parts individually or in groups or sets of parts. In the above photo, I put together a collection of spare dining chair parts to give you an idea of what’s possible on a 2’ x 3’ bed. You could also easily fit most stool legs, carved chair seats, cabinet doors and guitar bodies and necks. With repositioning, these CNCs are also long enough for dining chair back legs — always a challenge to shape—usually involving a number of dedicated jigs

Z height of 6” or more This gives the user the ability to cut thicker pieces of wood. And, it’s enough height to make 3D carving of objects like bowls, geometric, or freeform vessels possible. It also is deep enough to cut or carve some assemblies like a glued up rocking chair seat, a dining chair back or a cabinet door.

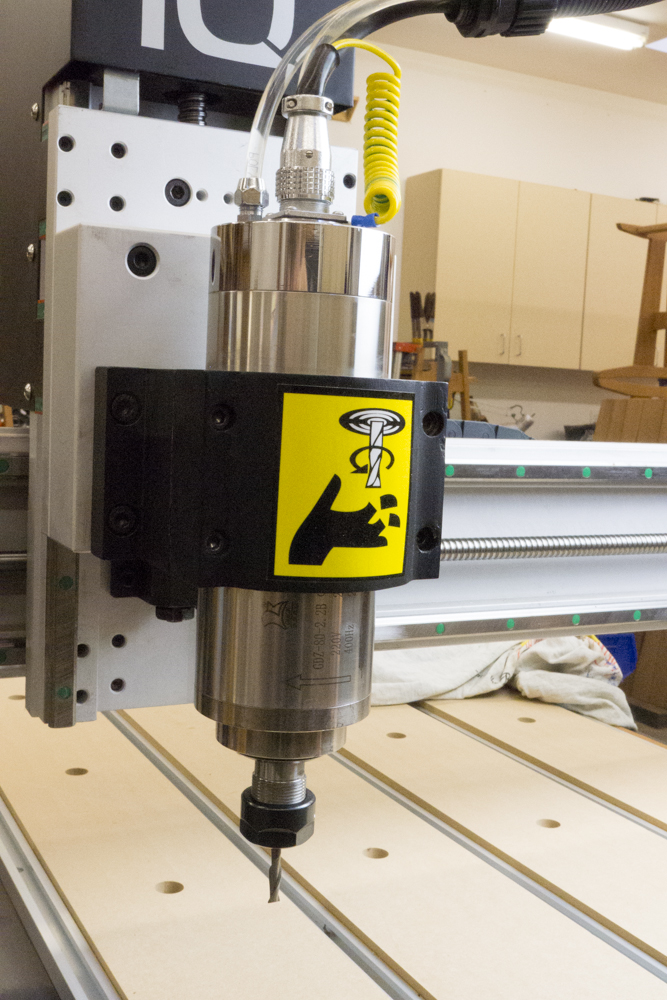

3hp Water cooled spindles have a lot of advantages over routers. For one thing, they’re much quieter. And, being forced cooled, they’ll last a lot longer than any router. Routers are typically run a few minutes at a time. But, it’s common to run CNCs for hours at a time and they are powerful for their size, infinitely speed adjustable and have high torque so they cut through hardwoods and aluminum easily.

Linear rails for guidance Precision linear rails keeps the machine accurately in line from one end of the table or gantry to the other; usually within a few thousands of an inch. The advantages are obvious: you get the exact results you were counting on in your drawings. Ball screws for precision motion Partnered with linear rails, ball screws keep the CNC movements smooth and accurate. Smooth motions are key to quality cutting. You really see the advantages of this combination when doing 3D carving. Pieces come out smooth to the touch.

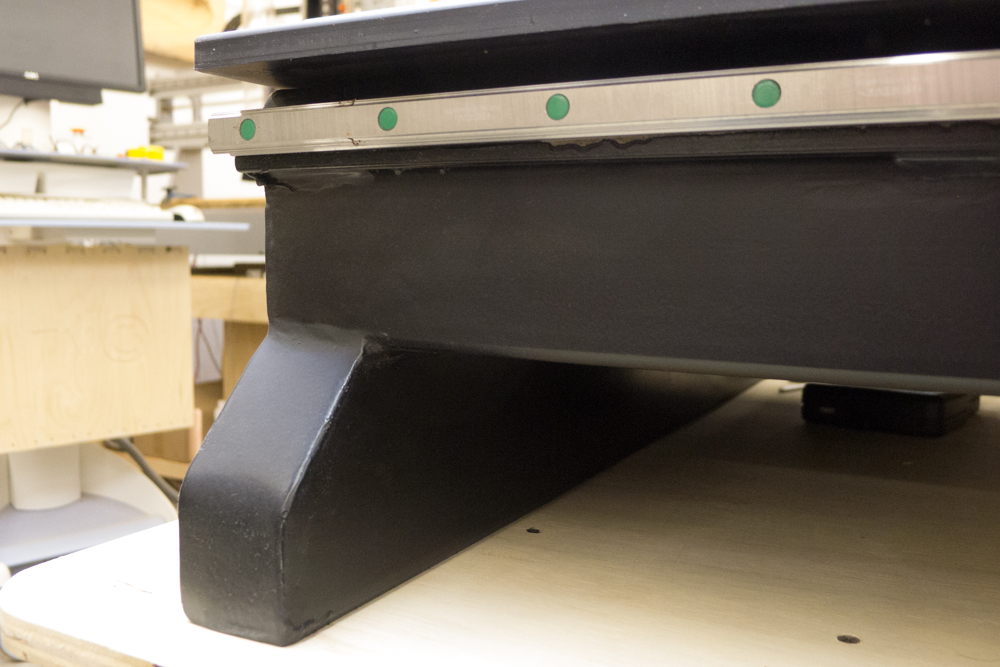

Stiff frame and gantry for strength and accuracy If you want the linear rails and ball screws to do their best then you need to put them on a strong foundation. Why? The weight of the gantry and spindle assembly pushes down at the center of the CNC’s bed. If the frame is weak then cuts in the center will not match the cuts at the ends. A stiff frame fixes all that. All these machines come with welded steel frames.

A simple pendant controller I like controlling my CNC with a dedicated computer but sometimes simple is better. Particularly for novices. All the CNCs in this class use the same RichAuto A11 controller and pendant set. You create your drawings on your computer, prepare them for machining and then generate the G code that all CNCs need to drive them. Load the file onto a thumb drive and plug it into the pendant. Once you set your Z height with the included touch-off block, just select the file and hit go. Simple.

What Can You Do With a CNC In This Class & Size Range

In the end, what matters most is what you can do with a machine of a given size or class. The 2′ x 3′ to 4′ size of these machines crosses the threshold from small specialty uses of smaller CNC machines into more general woodworking purposes like part cutting. The engineering, design and build quality of all these machines are high. Here’s a list of some of the things that you could do with a CNC of this size.

- Cut most small to medium furniture parts and with a few tricks even longer pieces.

- 3D carve cabinet or furniture details

- 3D carve sculptural objects and vessels up to 6″ deep

- Surface plane slabs up to 24” wide

- Make dedicated jigs, fixtures and clamping cauls for specific tasks

- Enough room to make multiple parts at the same time

- Stout enough to machine harder woods, aluminum, and hard plastics precisely.

- Enough clearance for milling sub-assemblies

- Enough clearance and precision for two-sided machining

- Precision joinery

- Plywood projects

Who are these digital tools are appropriate for? The kind of woodworker who’s likely pretty serious about their hobby or might be making a run as a small professional shop. They probably already have other good quality power tools and see a small CNC as a nice addition. But, they also make sense for newer woodworkers focused on hand tool woodworking and haven’t yet fully equipped a small shop and see a CNC machines as an alternative to some larger fixed tools.

There are other solutions in this size range. Including less expensive ones. We’ll look into those machines and others for those on a tighter budget later on. Though these CNCs start at $6000 and are certainly a considered purchase and may not for everyone, what makes this group so notable is the combination of select components, well thought out design and solid engineering. Measured against those factors and the much more expensive prices that we’ve had to pay until recently for this level of CNC, they are a good value. Plus, unlike most CNCs of this caliber which are usually 4′ x 4′ or larger, these fit nicely in many small shops.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

As someone viewing this from outside the USA I am surprised that you do not list Legacy amongst your small shop CNC machines given that unlike some mentioned I think you will find are not built in the USA.

Not only do Legacy build excellent machines but the also supply the thing that many people require training.

So why are they not in your list?

I’ve run 12 hours on my water cooled spindle on my 5 axis Legacy CNC.( https://lwmcnc.com ) Using an IR temp gun it showed no change in temperature. By my records after 3 years the spindle is still running the same temperature.

What happens if you run a water-cooled spindle for hours – doesn’t the water eventually heat up?