We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

A few weeks ago I was gifted an old wooden ammunition box that had one of its handles missing in action. The box also suffered from a few other structural issues, including a lengthy crack on one of its sides. Last weekend I decided to spend some time with the box and restore its structure and hardware.

A few weeks ago I was gifted an old wooden ammunition box that had one of its handles missing in action. The box also suffered from a few other structural issues, including a lengthy crack on one of its sides. Last weekend I decided to spend some time with the box and restore its structure and hardware.

After aligning and clamping the two split parts of the box’s damaged side, drilling pilot holes and counterbores (to accommodate the screws) I spread glue inside the crack and drove the securing screws home.

A closer look at rope handles

Rope handles used to be so ubiquitous in inexpensive furniture, in tranks, and in various boxes. The simplest form of a rope handle is a piece of rope that has been passed through two holes in the side of a box and then two knots were tied on both ends of the handle to secure it and prevent it from being pulled out of the holes.

I have used this technique many times but I never liked the bulbous knots that take up space in the box’s interior.

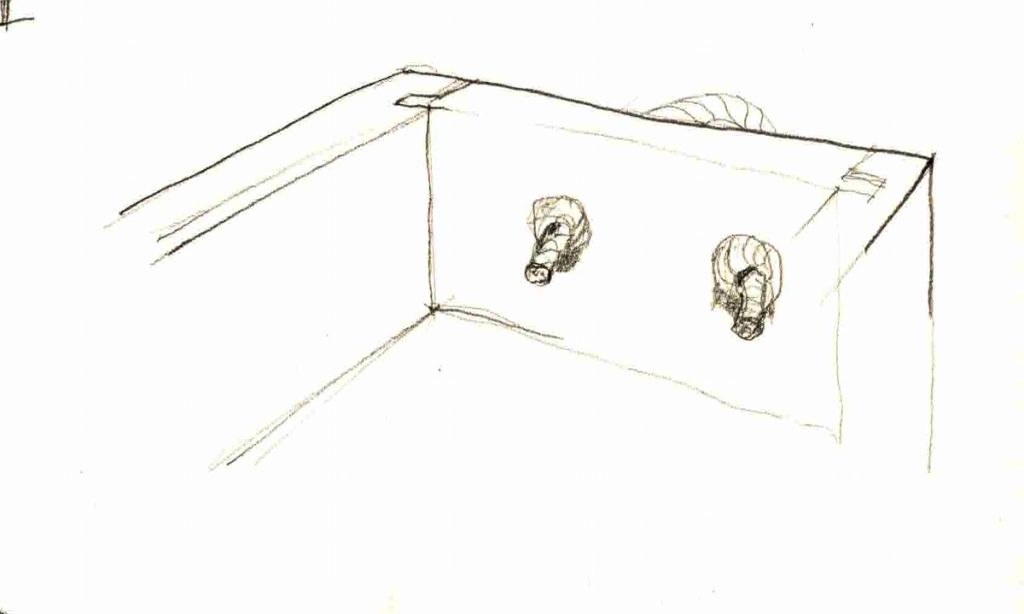

The box I repaired had a different kind of rope handle with no knots to disrupt its inside. Instead, the handles were encapsulated in the side’s middle batten which was connected to the panel with many clenched nails. A further examination of the two handles revealed that one of them had been nested in an undamaged batten while the other’s handle batten was damaged and its lower portion was broken.

The torn handle and its broken batten.

Removing the damaged batten and rebuilding it was out of the question as extracting all the clenched nails would have distorted the interior of the box, plus I was up for a quick repair and not for a museum-like conservation project.

As I tried to understand how the handles were nested and secured in place I discovered that the battens had been grooved and dadoed to allow the rope to nest inside. Two hefty clinched nails secured the rope via the batten and affixed it to the dados and the boxes panel while hidden nails secured the rope ends to the long groove at the bottom of the batten.

Replacing the handle

- First I remove the two clinched nails with a cat’s paw.

- Then I removed the secondary nails that connected the old rope’s ends to the batten’s groove.

- I glued some of the batten’s broken parts back with super glue and cut a new rope segment for the handle.

- I taped the ends of the rope and inserted them into the batten’s dados.

- After tucking the rope into the horizontal groove I secured it in place with “U” shape Double Point Staples. For lack of convenient hammer access, I used Knipex pipe plumbing pliers to press the staplers around the rope and into the soft pinewood of the batten. I was astonished by the amount of pressure that these pliers were able to produce.

- Then I hammer two long nails through the batten into the rope and out through the side of the box.

- Then I clinched the nails for extra security. To do this, I bent the nail’s tip with pliers and then hammered the nail to fold over the wood. To prevent the nail from retracing backward I used a handheld hammer-like block of steel and placed it against the nail head to provide counterforce as I hammered and bent the nail’s tip from the inside of the box.

- After regluing the broken batten part my triage repair was completed.

After learning how this compact and inexpensive handle was constructed I think that I will try to incorporate this design in future projects. I might use modern ropes or stick to traditional materials such as sisal or hemp. I might glue the rope into the batten instead of using nails or staples and I might even make the batten shape more elegant. It all depends on the project and where it will take me.

To learn more about how to clinch nails take a look at this video by Christopher Schwarz.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.