We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

“Safety first” is a good saying, but sometimes it’s tempting to believe that safety is just a box at the top of a mental checklist – the “check it off and move on” attitude. To the contrary, it’s best if you treat safety as a technique – an in-depth subject to revisit throughout your woodworking journey. I find that there is even more to learn about safety once I have tried a few things and possibly experienced a few mistakes.

Marc Adams, one of America’s premier woodworking instructors, has the gift of making power tool safety rules easy to remember. He also makes it a topic that all woodworkers can learn from, regardless of experience levels. Today I’m presenting just one of Marc’s three major factors in table saw safety – control. To get the other two – exposure and limitation – click here.

And to get all of Marc’s woodworking technique instruction in video format, buy the DVD collection from our store. It’s a fantastic value for the amount of knowledge these videos contain!

–Dan Farnbach

Table Saw Safety Rules, Part One – Control

by Marc Adams

The following is a list of six factors that are important to gaining better control of your work at the table saw.

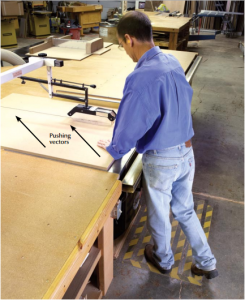

1. You must have a firm stance at the machine. Your starting position will vary depending on the size of material and type of cut being made. I definitely recommend that you stand to the left of the blade with a pushing vector toward the fence and away from the back of the blade. I like to firm up my stance by placing my hip against the saw itself; this gives me better support. Never stand directly in front of the blade or in direct line of potential kickbacks.

2. Maintain control while pushing the stock through the saw. Never cut freehand on a table saw – always use the control surfaces, such as the fence or miter gauge. When ripping wood, I dedicate my hands so that my right hand provides the forward push and my left hand pushes the wood against the fence – make sure to maintain 3″ of clearance from the guard with both hands. It is OK to stop feeding a board during the middle of a cut to reposition your right hand or to pick up a push stick, but you must never let go of the stock with your left hand during this transition. Once the cut is complete you need to make it a rule and habit to not reach over the saw blade to pick up the stock – even with the guard in place.

3. Maintain good eye contact. Learn to keep your eyes in tune with the fence and the guard (instead of the blade). Most people want to stare down the blade as it’s cutting the wood, but with the guard over the blade the cut is obscured and will tell you very little. Concentrate mostly on the control between the work and the fence. Visualize where the 3″ rule is and develop a good awareness of this zone.

4. Learn how to control oversized material. I know most shops are limited on space, but it sure is nice to have extra table surfaces around the sides and especially the back of the saw. If you have someone helping you with large stock, make sure you practice first and make sure you are in control of the cut. The helper should just act as a table extension. If a helper is not available, use a roller support.

5. Know the right feed rate. The rate you feed the stock in the cut can be affected by many factors including the differences between ripping and crosscutting, the type of blade being used and its sharpness, the type of material being cut, and the power of the saw. Sometimes just listening to the cut will tell you more than anything else. You should never force the cut to the point where the blade stalls. If the edges of your board are burning, try to speed the feed rate a bit. If that doesn’t improve the burning then the blade is probably getting dull or needs a good cleaning.

6. Understand the built-in controls on a table saw. To counter kickback, engineers have built in “control” as a way to manage the undesirable effects of the wood when it contacts the blade. The table itself, the fence, a miter gauge, standard guarding, specialty devices such as push sticks, feather-boards and hold-down devices, are all great ways to control the stock as it meets the point of contact on a rotating blade.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Many may not know this. But thanks for highlighting the importance of safety when using table saws. Well-written research. http://www.woodworkingbank.com