We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Among the smoothing planes that Stanley Works made (which includes the Nos. 1 to 4), the company sold far more No. 4s than any other size, according to Stanley collectors.

That was my rationale for buying a No. 4 many years ago. I still think it’s a good size for a handplane, with a 9-1/2”-long sole and 2”-wide iron, which allows you to use the iron in the No. 5 jack in a pinch.

Like many late-20th-century woodworkers, I also tried for a time the No. 4-1/2, which is wider and longer than all the other smoothing planes. That tool wore me out. Not because of the extra weight per se, but because I had to smooth panels a lot more to get into the minute hollows and to remove tear-out there. Its big sole wants to ride the high points of a panel.

During the last few years, I have felt the pull of even smaller planes. I tried a No. 3. It was faster than my No. 4. Then I tried the No. 1, but it doesn’t have a lateral-adjust lever, a feature I am fond of.

So I’m working with a No. 2 now (here why and here’s how to set up its back iron).

And though you might think I’m a bit cracked, I think a lot of deceased woodworkers would agree with my approach. I first got this notion years ago during my first tour of John Sindelar’s tool collection. His once-immense collection had metallic and wooden-bodied planes from every era, from the 16th century to the present.

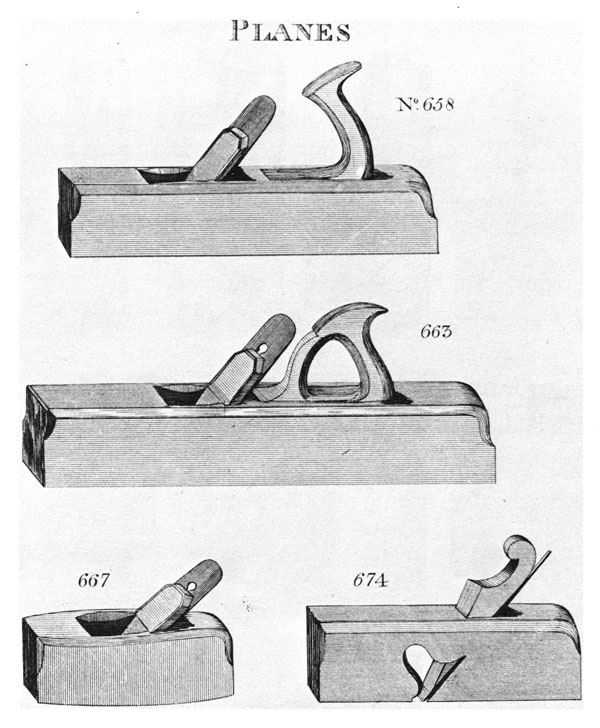

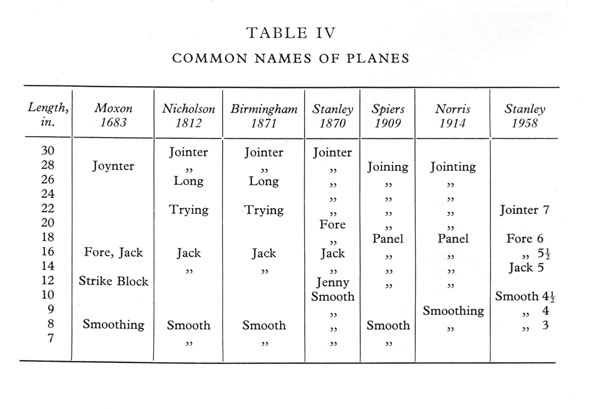

With so many hundreds of examples before me, I was struck by how small the early smoothing planes were (and how long the jointers were). A quick review of W.L. Goodman’s “The History of Woodworking Tools” confirms my suspicions, with early smoothing planes typically being 7” or 8” long.

Is there a difference in a plane that is 1” or 2” shorter and 1/2” narrower? I sure think so.

The other question I get about this approach goes something like this: “Wait, if you’ve used a jointer plane to flatten a panel, then shouldn’t any smaller plane immediately be able to plane all points on the surface?”

While that is generally a true statement, it doesn’t reflect how I work. I use a jointer plane on surfaces that have to be flat – edges of panels and the interiors of casework panels (that’s where the joinery goes). When it comes to the outside of a case piece or a tabletop, it has to only look flat – not be flat.

So I’ll go from a machine thicknesser straight to a small smoothing plane. This leap allows me to get a panel dressed and ready for finish in very few strokes.

Now I just need to modify the tote of my No. 2 to see if I can get it to work like the tote for a No. 2-sized plane from Millers Falls. That should allow me to hold the No. 2 with a variety of grips. I don’t have any cherry in my wood racks, so it looks like I’m going to be using some teak scraps for the tote and knob.

— Christopher Schwarz

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Chris:

I have a #3 Stanley that I’m beginning to love a lot.

By-the-way, Here in the U.P. we’re in Cherry and Curly Maple heaven. I just finished a large cabinet in Cherry and have several 2″ thick “cut offs” that would be perfect for tote handles. I’d be glad to send you one or two.

Back in my boating days I learned to hate Teak.

Ralph

I’m really looking forward to how using the No. 2 goes .. AND .. I’m so glad you’ve been writing about this because I’ve been struggling with this exact problem.

PS. See ya at Handworks!

what’s the advantage of a #2 over your Anderson small smoother?

Ditto on the sensitization. I used to use my bare right hand to process black & white photographic prints. After twenty plus years of doing so, I now have “contact dermatitis” in my right hand. If I go anywhere near a tray of Dektol with my right hand my cuticles blister and bleed within 24 hours.

Suffice to say, Chris, it could take years to become allergic. Take precautions. Avoid sanding whenever possible or do it outside with a fan keeping you upwind of all.

So, what’s so great about the Millers Falls plane’s tote ? And, if it’s good, why not just use it ? Don’t leave us hanging Chris !

thanks

stephan

Teak is listed as “irritant, sensitizer, rash, nausea” in “The Wood Database”. Is there some other wood that you might use rather than teak? You’re going to have your hands on the tote a lot – not just touching the wood occasionally while you make something else.