We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

First a disclaimer: This is a recollection of impressions following the installation and test running of our new 6” Grizzly spiral Cutterhead jointer, that we bought at full price this fall.

First a disclaimer: This is a recollection of impressions following the installation and test running of our new 6” Grizzly spiral Cutterhead jointer, that we bought at full price this fall.

As many of you know, I teach woodworking at the Rudolf Steiner School in Manhattan. Our program is mainly geared towards hand tool work. To help us prepare stock for projects, shop furniture and to create projects for our Fall Fair workshop & sale, we have a few stationary woodworking machines on board. In our tiny basement shop, we house a Sawstop cabinet saw, two 14″ bandsaws, a drill press, a few sanders, a scroll saw and as of September, a jointer and a planer.

When I researched options for the jointer and planer I read a few articles, searched the web and relied on my own experience with woodworking machinery. Budget, performance and reliability ranked highest on my list of criteria. I don’t care much for how the machine looks and I am happy to spend some time installing and adjusting a machine if I can save our program a few bucks – rather than buying top-notch, spruced up machine and spend a premium.

There are times when we mill extremely hard woods such as eucalyptus and locust, and because I’ve witnessed the fabulous practicality of having carbide inserts on jointers and planers, I decided that we should buy a spiral cutterhead jointer. Working with some Grizzly machines over the years, including in craft schools and other woodworking programs, I decided to go with this brand. It was a long waiting period, as the specific Joiner we ordered was out of stock, but eventually, we got ours in early September. It took me a few hours to install and adjust it. Here are my observations.

- This Grizzly machine is greasy, but that is a good thing, as the grease protects it during shipping. Be ready to spend some time degreasing the infeed and outfeed tables, and other components including the fence.

- Hanging the motor correctly and tensioning the belt is finicky. This is the case with many woodworking machines, but still, I’m hoping for future improvements in this field. Trying to keep the motor dead horizontal while attempting to align its pulley arbor with the cutter head’s pulley, and at the same time put the proper tension on the belt is challenging. You need to work your way keeping them coplanar while tightening the mounting bolts, which is a trial and error process. Grizzly’s engineers need to come up with an easier alignment and belt tensioning mechanism that is more dependable. With the current system, someone with an anal retentive personality can be left with a frustrating feeling that the belt is over tensioned or that the pulleys are not perfectly co-planed.

- All the other mechanisms work very well. The tables and the fence are very flat and been precisely milled and surface ground. I really like the elevated on-off switch and the integral mobile base, which is very handy in a small shop like ours.

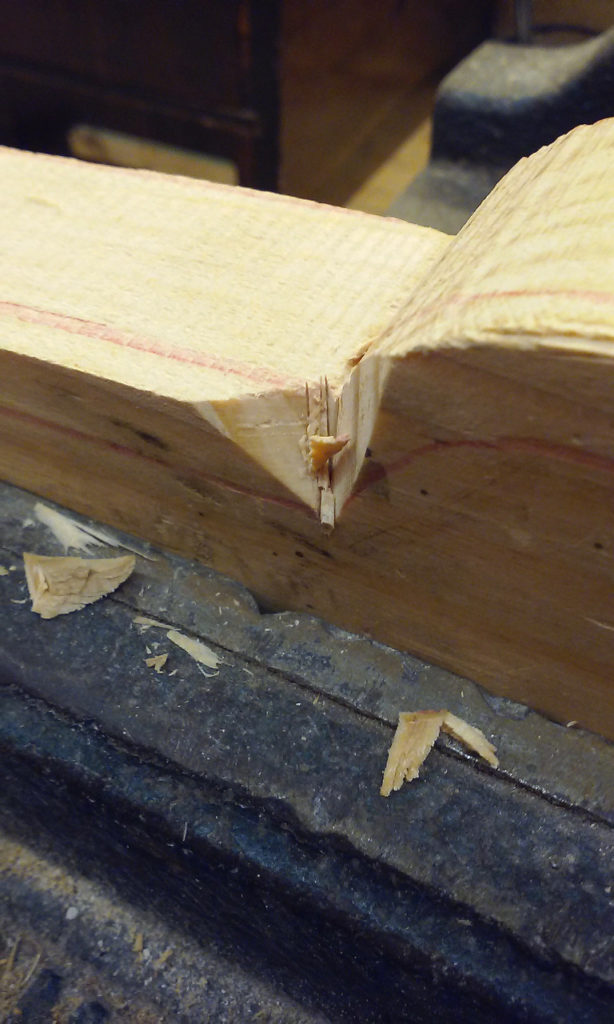

- The mobile base’s third wheel is one issue that new owners of the jointer need to take care of. If you move the machine and hit a raised spot or a dimple on the floor, the cam mechanism collapses and the jointer drops a quarter of an inch or so to the floor. I had experienced this with a Grizzly 8” jointer too. To prevent that I built a special wedge which I tuck behind the wheel’s cam lifter whenever the machine is in its “cruise mode”. It’s a tiny thing to fix and the grizzly people need to know about it.

- The manual is in general coherent, although I don’t recall seeing an entry about how to adjust and calibrate the fence to 90 degrees and 45 degrees. That’s said, it’s quite self-explanatory and straightforward for anybody who worked with stationary and power tools of that sort before. To adjust the fence you need to untighten a nut, then advance or retrieve a bolt, tighten back the nut and you’re good to go.

At a cost of around $900 the Grizzly 6” jointer is probably the best carbide cutterhead jointer in its class.

Our new jointer is now ready to rock and roll. It’s a nice addition to our program and I’m confident it’s going to serve us well for many years to come.

See below how I made the wheel cam wedge.

Power Tool Essentials: The Jointer & Planer

Power Tool Essentials: The Jointer & Planer

Straight, Flat & Parallel…No Problem!

Meet the dynamic duo of lumber preparation. The jointer makes boards straight and flat, then the planer finishes the process by machining a parallel board to an exact thickness. Doug Dale shares his years of experience with both so you get the best results.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Hi Yoav. This planer looks a lot like the old Delta x5 6″ jointer, a Taiwanese machine. Since the Grizzly is an import also is this your impression? What caught my eye was the silly motor alignment and belt tension arrangement.

Thanks,

Ray